Hi Jojo

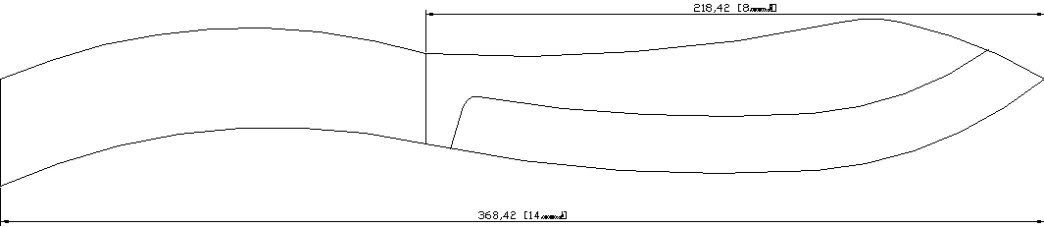

Now that Grohmann Survival inspired knife is a beaut', a definate improvement on the factory job!

I don't know if I'm inspired or depressed because anything I do will be a abomination compared to that!

ATB

Tom

On the vague note of knives, I've just refound the bloody great bronze magazine knife I won on ebay for no good reason. Maybe I should liquidize some of my pointless aquisitions and get the big nesse made?!

Maybe it will, but I doubt it. The hardest bit of making a knife is, wait for it.......rolls of drums....to actually start! Bit of a disappointment there!

What I do normally is to make a card template, (side of a cornflakes box type) then if I am happy with that, I make plywood template. It's all cheap and easier to cut than the steel. When you got a ply template you're happy with, make as soft wood handle for it, that helps you with getting a feel for what the knife will be like in reality, and helps give you some confidence.

If you can make a shape in cardboard, you can make a shape in ply. If you can make a shape out of ply, you can make a shape out of metal.

Then you can trace around your template on the steel, I tend to use a fine permanent marker for that.

I use a angle grinder to cut the blanks but you can also use a pillar drill to drill holes all the way around, it takes a bit longer and less likely to slip. If you are not used to the grinder, it work well too. Then use a big coarse file to get closer to your pattern, then finer ones.

Next step is to show us some pics of your progress! It will give you a great feeling of achievement when you've done your first knife.