Tom, You have had a real Bargain buy with that draw knife. You are hard pushed to find one on ebay for under £20.

More carboot tools

- Thread starter tombear

- Start date

-

Come along to the amazing Summer Moot (21st July - 2nd August), a festival of bushcrafting and camping in a beautiful woodland PLEASE CLICK HERE for more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oh aye, not often it happens but when it does, a real bargain that is, it's very good for morale.

got to a boot today despite herself being away at scout first aid training, the bus was remarkably conveniant for once, didn't get much relevant stuff, I'll spare you the pottery etc but what I got was all dirt cheap.

Wm. Whitehouse Atlas Forge Made in England double ball pain planishing hammer, nice small heads £2. Been after one for a while

2 seiger type can openers 33p each, the best condition one , the silver is marked "Clou" "foreign" I've tarted up to go in the collection. The black I've cleaned as a user. You can still get them new for about 12 quid.

2 church key can openers, 10p each, ones Guiness, the others Scotish and Newcastle Breweries.

Beech rolling pin pin for turning, 50p

Sheffield made sharpening steel 33p

box of 14 boxwood clay sculpting tools and 8 home made steel ones £2

cleaned everything except the boxwood tools.

not a huge haul but all dirt cheap!

ATB

Tom

got to a boot today despite herself being away at scout first aid training, the bus was remarkably conveniant for once, didn't get much relevant stuff, I'll spare you the pottery etc but what I got was all dirt cheap.

Wm. Whitehouse Atlas Forge Made in England double ball pain planishing hammer, nice small heads £2. Been after one for a while

2 seiger type can openers 33p each, the best condition one , the silver is marked "Clou" "foreign" I've tarted up to go in the collection. The black I've cleaned as a user. You can still get them new for about 12 quid.

2 church key can openers, 10p each, ones Guiness, the others Scotish and Newcastle Breweries.

Beech rolling pin pin for turning, 50p

Sheffield made sharpening steel 33p

box of 14 boxwood clay sculpting tools and 8 home made steel ones £2

cleaned everything except the boxwood tools.

not a huge haul but all dirt cheap!

ATB

Tom

Aye, I've made myself a little leather sandbag thing, need to score some sheet copper or something, and a book about beating metal! I've a blowtorch for anealing.

atb

Tom

atb

Tom

Well I didn't have any suitable tubing for collars so the handles will be a bit more fragile than I'd have liked but they are on and a good fit to my hands. I used a carboot rolling pin for the wood, a convenient source of round section seasoned beech. I only pick them up when they are under a quid.

I've put six coats of linseed oil on them so far. I filled the gaps with araldite and riveted the washers onto the ends of the tangs so the handles are well fixed on. Now to put a final edge on it. I'll do a cover for it over the weekend.

i've recently tried out oxcillic acid for derusting but except for cases where there's chrome ( which ox' does not effect ) I've gone back to Citric acid for general use. It seams to work better on deep rust and is much cheaper and less toxic. Ok the nasty black residue it leaves behind needs to cleaned off but a wide wire brush on a bench grinder sorts that quick enough. Best to have a light touch for that if there's cutting edges to preserve.

Solution strength? Well a heaped tablespoon per quart of boiling water is what I normally use and a soak of under a hour. More and longer if it needs it. Once out of the solution I dunk it in boiling water to heat the metal up and pat it dry with rags, the heat of the metal will finish the drying of any crevices. After getting rid of the residue that forms I oil the item and buff that off with more rags then lightly oil it again before sharpening or what ever else needs doing.

ATB

Tom

In the end I took three grades of diamond stones down to superfine on the back of the blade then gave the edge a quick wipe with a ceramic rod. It's pretty sharp but the angles not as low as on my others so I may need to lower it.

Thanks for the feedback on solution strength and duration - that's really helpful.

Knocked up a edge guard for the latest drawknife. Took a piece of scrap pine, put in a 10 inch lline of 1/4 inch holes in withe the morticer, one inch down to make the slot for the blade. Trimmed the wood so there was a inch each side and half a inch on the bottom, used a gents saw and 1/4inch chisel to clear out where the shoulders of the blade needed to go so there's about a 1/16 th of a inch clearance on the inside so the cutting edge isn't in contact with the bottom of the slot, gave it a quick sand to take the corners down, gave it a rub with linseed oil, pilot drilled and tacked on two straps cut from scrap leather, screwed on a pair of male awning presstuds, marked the leather with the knife in place , made holes and hammered on the female parts of the presstuds.

OK it's nowt to look at but it will do the job fine.

ATB

Tom

OK it's nowt to look at but it will do the job fine.

ATB

Tom

Well I forgot about this one to the extent that the steel bits where left in the citric for three days. They cleaned up fine anyway. The thin blades are fairly useless, the nominally metal cutting one needs shortening to where the chips are.

Stiil, for a quid it ain't bad, semi disposable. No markings, not even "Foreign".

Stiil, for a quid it ain't bad, semi disposable. No markings, not even "Foreign".

Just a small haul today, Burnley flea and Colne charity shops

Donor rolling pin, 50p

4 old school packs of quality UK made needles £1 the lot.

Made in England Stanley Yankee drill with 8 different as new drill bits ( made my day that one ) £2

8 x 100gm balls of chunky pure new wool £1.20 a pop

so its worth looking!

atb

tom

Donor rolling pin, 50p

4 old school packs of quality UK made needles £1 the lot.

Made in England Stanley Yankee drill with 8 different as new drill bits ( made my day that one ) £2

8 x 100gm balls of chunky pure new wool £1.20 a pop

so its worth looking!

atb

tom

I'm downsizing now = a good clearout!

The charity shops and Freegle are benefiting - but it does make me wonder if all these "bargains" were really worthwhile...

True, I've done lots of repairing, upcycling, making, and projects, but I can see already that with minimal kit, & NO retail therapy, I'll be bushing more!

The charity shops and Freegle are benefiting - but it does make me wonder if all these "bargains" were really worthwhile...

True, I've done lots of repairing, upcycling, making, and projects, but I can see already that with minimal kit, & NO retail therapy, I'll be bushing more!

Couldn't get to the flea on Saturday as was planting all morning then Sunday it was the Scouts St George's Day parade and service which meant my chaufeurs and 2 out of three bearers were not available, it also rained on and off so I stayed at home making stuff.

Anyroad I swanned off to get some bits I needed from the excellent Fletchers Hardware in the valley and since I was out carried on to do a tour of the local towns. It was a bit truncated as in one charity shop I got pretty much a whole Denby dinner service for £25 but as ever I digress.

Being rather knee knee deep in all wool blankets I turned my nose up at one of two ( cream, good nick but I've a dozen like it ) all wool blankets but I liked the colour ( is darker in real life ) of the other and blew a whole fiver on it ( as of about 1 today the other for the same price, was in the RSPCA shop in Accington, 90 inch wide, Moderna, ).

The three drills cost me £2 the lot from the bargain bin in the same low end antique shop I got the other. The two all metal ones are marked Hobbies MADE IN ENGLAND , no markings on the other. They should all respond well to TLC and I'll load them with different sized drills, or maybe make a tiny ring and dot maker to fit one.

RV, I think I have a match box like pack of the small flat bits you describe, somewhere. I need to find the bag of not worth restoring files anyway so I'll see if they are in the junk box. I did let someone have one of these drills a few years back so they may have gone with those. Mind like you said, easy enough to make some. I've found this sort of drill very good for working bone and horn, putting in holes for quite small. Needles and such.

ATB

Tom

Anyroad I swanned off to get some bits I needed from the excellent Fletchers Hardware in the valley and since I was out carried on to do a tour of the local towns. It was a bit truncated as in one charity shop I got pretty much a whole Denby dinner service for £25 but as ever I digress.

Being rather knee knee deep in all wool blankets I turned my nose up at one of two ( cream, good nick but I've a dozen like it ) all wool blankets but I liked the colour ( is darker in real life ) of the other and blew a whole fiver on it ( as of about 1 today the other for the same price, was in the RSPCA shop in Accington, 90 inch wide, Moderna, ).

The three drills cost me £2 the lot from the bargain bin in the same low end antique shop I got the other. The two all metal ones are marked Hobbies MADE IN ENGLAND , no markings on the other. They should all respond well to TLC and I'll load them with different sized drills, or maybe make a tiny ring and dot maker to fit one.

RV, I think I have a match box like pack of the small flat bits you describe, somewhere. I need to find the bag of not worth restoring files anyway so I'll see if they are in the junk box. I did let someone have one of these drills a few years back so they may have gone with those. Mind like you said, easy enough to make some. I've found this sort of drill very good for working bone and horn, putting in holes for quite small. Needles and such.

ATB

Tom

There are a few examples of Inuit (Nunavut) bow drill kits in the UBC/MOA online collection. Animal rib for the bow, leather for the cord. The drills appear to be bone with a simple iron nail(?) for the bit and a vertebra bone for the bearing cap.

I can easily adapt my fire-making bow drill to drilling holes in stone/bone. I have some Inuit soapstone carvings, several details appear to have been drilled.

"Hobbies." Somewhere recently, I've seen pictures of the entire "Hobby" kit which included the drill that you illustrate. Quite sure that my drill is all that remains of my Father's hobby kit of tools. If my memory serves, some of the drill bits had square shanks in the style of sewing machine needles.

I can easily adapt my fire-making bow drill to drilling holes in stone/bone. I have some Inuit soapstone carvings, several details appear to have been drilled.

"Hobbies." Somewhere recently, I've seen pictures of the entire "Hobby" kit which included the drill that you illustrate. Quite sure that my drill is all that remains of my Father's hobby kit of tools. If my memory serves, some of the drill bits had square shanks in the style of sewing machine needles.

Didn't find the pack of bitts but they may still be somewhere, possibly inside one of the innumerable 2oz tobacco tins that are floating about. We did find another drill, must have been in a job lot, a bit rough wood wise but nowt I can't copy if needs be.

Also so policed up about enough bits of horn, bone and antler to fill a shoe box. I've bought a new pack of dust masks so may have a go at making some more stuff from it.

atb

Tom

Also so policed up about enough bits of horn, bone and antler to fill a shoe box. I've bought a new pack of dust masks so may have a go at making some more stuff from it.

atb

Tom

Last edited:

The "slider", shall I call it, was metal with a ribbed rim at each end. Nice to see such diversity in what must have been a functionally useful design.

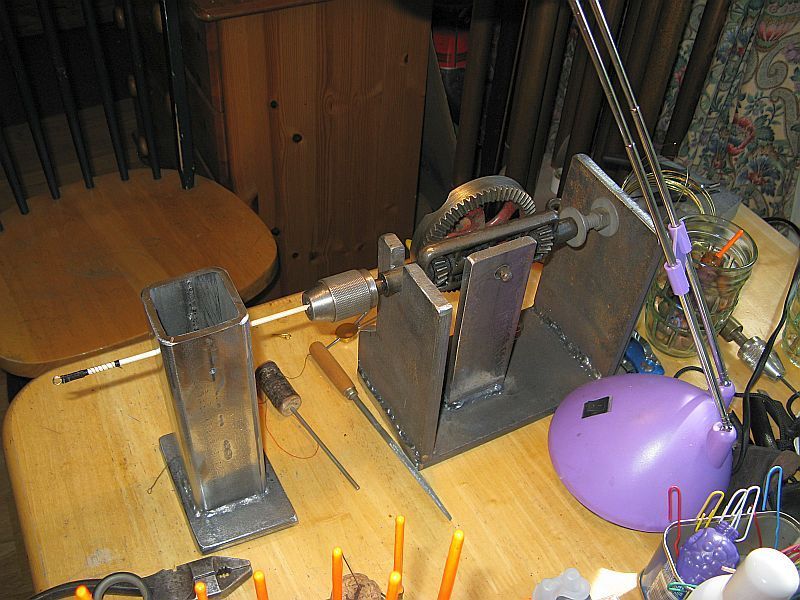

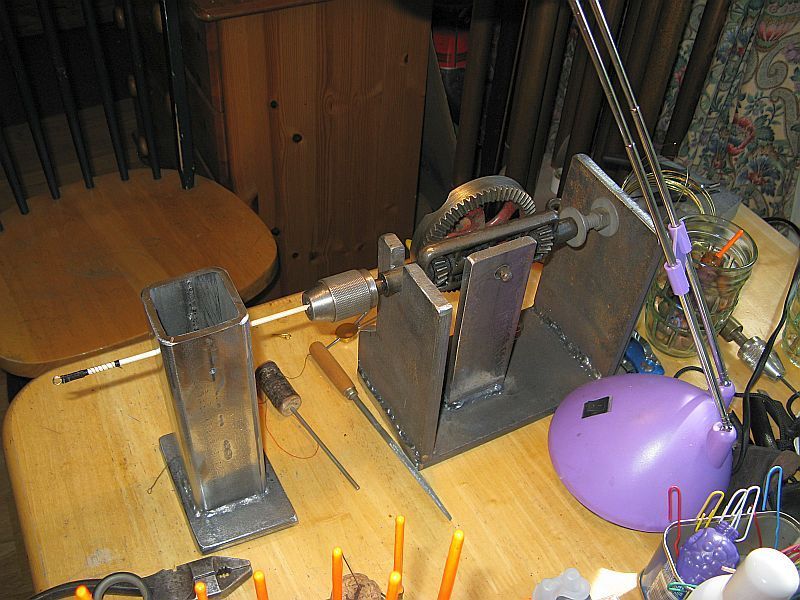

Wanting a 'hand drill' I visited Toms' Tool Guy on Colne market and on explaining what I wanted it for he came up with one from his 'parts' bin for £2

back to the Shed and the 'it'll come in handy one day' junk/scrap pile it was out with the Aldi welder

and being used to make Fishing Floats http://http://www.bushcraftuk.com/forum/showthread.php?t=139509

it also winds bobbins for my Singer sewing machine

back to the Shed and the 'it'll come in handy one day' junk/scrap pile it was out with the Aldi welder

and being used to make Fishing Floats http://http://www.bushcraftuk.com/forum/showthread.php?t=139509

it also winds bobbins for my Singer sewing machine

That's excellent! A lot like some old jewelers lathes I've seen.

I really need need to get a stockpile of metal made, and get a welding rig!

I take it it you mean the guy on the indoor market? There's a guy who did do the outdoors one on a Saturday as well but wasn't there the last Sat we went.

It's a a bit of a haul from here to Colne but there's a good chippy on the street down the right side ( going in ). Only place I know that has a bowl of chopped up onion in a strong vinegar on the counter for customers to help themselves to. The butchers inside the market hall still sells big oval thrown oatcakes, both soft and dried. Only place I know that does them dried to cater for grannies who still like to crumble them into stews and alike.

atb

tom

I really need need to get a stockpile of metal made, and get a welding rig!

I take it it you mean the guy on the indoor market? There's a guy who did do the outdoors one on a Saturday as well but wasn't there the last Sat we went.

It's a a bit of a haul from here to Colne but there's a good chippy on the street down the right side ( going in ). Only place I know that has a bowl of chopped up onion in a strong vinegar on the counter for customers to help themselves to. The butchers inside the market hall still sells big oval thrown oatcakes, both soft and dried. Only place I know that does them dried to cater for grannies who still like to crumble them into stews and alike.

atb

tom

Last edited:

You could no doubt adapt one or more of your hand drills into a ready made fire making bow drill too!

Tom.

Tom.

Oddly enough I once started a thread asking if anyone had tried using a Yankee screwdriver instead of a bow drill. I may give it a go although I can't see anyone ever taking one out into the sticks!

atb

tom

atb

tom

Between times I've cleaned up the other 4 drills, now all running smoothly.

Went for another wander yesterday, mainly to get some knackered old files to use as stock when the mini forge is up and running, which I failed to do much to my surprise but did come back with 1.5Ks worth unpainted Games Workshops minitures and stuff which will be going on eBay to fund my tool fetish! Well I'll be keeping the case with 75 odd paints and inks, tools etc and the youngest has had the two special suitcase things to put his Necrons and undead armies in, but all the rest will go, pile em high and sell em cheap!

Atb

Tom

Went for another wander yesterday, mainly to get some knackered old files to use as stock when the mini forge is up and running, which I failed to do much to my surprise but did come back with 1.5Ks worth unpainted Games Workshops minitures and stuff which will be going on eBay to fund my tool fetish! Well I'll be keeping the case with 75 odd paints and inks, tools etc and the youngest has had the two special suitcase things to put his Necrons and undead armies in, but all the rest will go, pile em high and sell em cheap!

Atb

Tom

Last edited:

Similar threads

- Replies

- 15

- Views

- 831

- Replies

- 11

- Views

- 1K

- Replies

- 10

- Views

- 1K