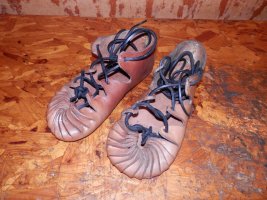

I have several times made felted shoes but so far I haven't figured out how to make a good sole for them. Leather only lasts so long and I'm growing wheat right now to try braided soles as a replaceable option but thought I'd ask here.

What is a good way to make a sole for a home made shoe?

What is a good way to make a sole for a home made shoe?