I have been on and off trying leather work for years and years now, pretty much since about 2008/09 since I discovered my grandfather (died before I was born) was a leather worker after his WW1 Service.

These are the first two things I ever made, very crude and naive as I didn’t know then the first thing about proper saddle stitching, how to punch holes, cut squarely or finish edges! But I am quite fond of them and use them for storing leather tools to this day.

These are the most recent few items I have made in the past month, mostly in the evenings after work. The stitching is quite different now! I really like the

headspace it gives me and enjoy the process of experimenting and learning.

Here are some notebooks covers and my first go at a possibles pouch with some basket weave stamping!

A note book cover I made for my sister-in-law, and a couple valet trays, a golf ball holder and a couple of minimalist wallets for some Christmas presents.

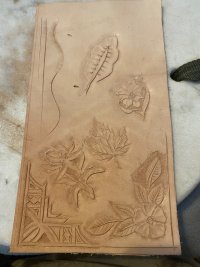

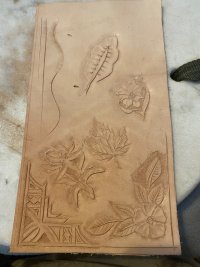

I have also recently tried learning tooling but after being given a whole boxful of tools, and it is *hard* but again I like the process. Can’t do it in the evenings as the ‘tappety-tap-tap’ drives the rest of the family nuts!

I don’t get out as much as I used to for various reasons, but would like to post projects and items I make here in lieu

Ed

These are the first two things I ever made, very crude and naive as I didn’t know then the first thing about proper saddle stitching, how to punch holes, cut squarely or finish edges! But I am quite fond of them and use them for storing leather tools to this day.

These are the most recent few items I have made in the past month, mostly in the evenings after work. The stitching is quite different now! I really like the

headspace it gives me and enjoy the process of experimenting and learning.

Here are some notebooks covers and my first go at a possibles pouch with some basket weave stamping!

A note book cover I made for my sister-in-law, and a couple valet trays, a golf ball holder and a couple of minimalist wallets for some Christmas presents.

I have also recently tried learning tooling but after being given a whole boxful of tools, and it is *hard* but again I like the process. Can’t do it in the evenings as the ‘tappety-tap-tap’ drives the rest of the family nuts!

I don’t get out as much as I used to for various reasons, but would like to post projects and items I make here in lieu

Ed