I love scavenging and making useful stuff from the free junk I find. Recently I explored a short stretch of highway and found a piece of leaf spring and a piece of juniper wood lying close to each other. I decided to combine them into a "highway knife." I roughed the handle out with an adze and knife.

Article: The Highway knife

- Thread starter forginhill

- Start date

-

Come along to the amazing Summer Moot (21st July - 2nd August), a festival of bushcrafting and camping in a beautiful woodland PLEASE CLICK HERE for more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yeah, that's brill,  , I'll pin that up as an article.

, I'll pin that up as an article.

Can you tell us a bit more about process you undertook to get such a great little knife...

, I'll pin that up as an article.

, I'll pin that up as an article.Can you tell us a bit more about process you undertook to get such a great little knife...

Lovely piece of work and like Tony I would be interested in reading a bit more on the process at each stage.

Cheers

George

Cheers

George

That's a cracking knife and I love the ethos behind it. Be good to see hear the whole process like has been suggested.

Funny too, I think this is the only place on the net where someone could call another member a Womble and it's meant & taken as a compliment.

Quality work and cheers for sharing.

Sent via smoke-signal from a woodland in Scotland.

Funny too, I think this is the only place on the net where someone could call another member a Womble and it's meant & taken as a compliment.

Quality work and cheers for sharing.

Sent via smoke-signal from a woodland in Scotland.

Thanks for the enthusiastic feedback, mates!

Tom, we have lots of roadkill, and I hadn't thought of that. I'll have to take on that messy project!

Tony, I'll add a few thoughts.

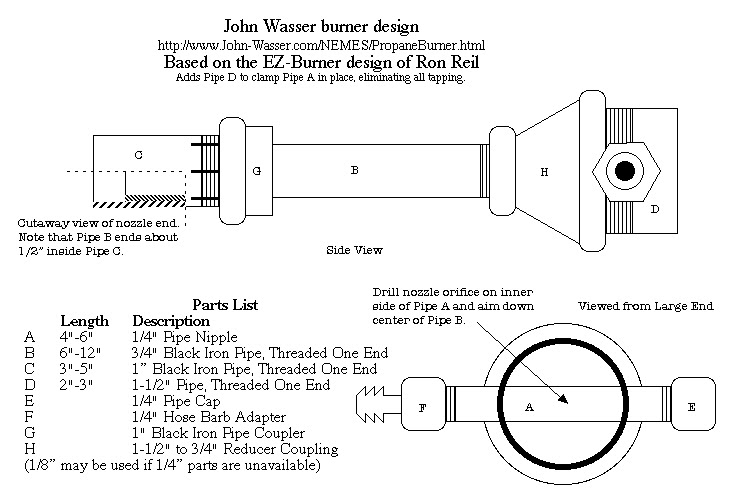

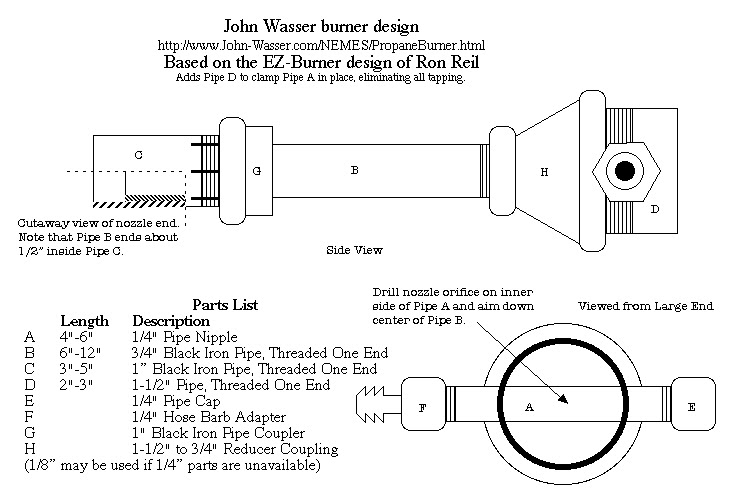

I use a homemade coffee can propane forge most of the time. I have a proper coal forge, but I don't use it too much because fuel is hard to get and it's not as convenient. I'll post the plan for the forge I use and the link to a short video of it. I'll also post a video that I made going through the basic forging process I use.

I like to take my blade to very near its final edge. For heat treating I close the choke on the burner to get a reducing fire, which is really low pressure. This gives me lots of control, and I don't have any problem with a decarbonized surface on the edge. I normalize the blade three times and quench it three times in canola oil. A metallurgist told me it is almost the equivalent of the high price fast commercial heat treating oils.

For this one I cut some notches in the tang and just epoxied it into the handle. I am an avid carver, and I carve lots of hard wood. I've never had this system fail on me. I've destroyed a few knives on purpose to see how secure they were. It took some beating with a hammer just to get the handle off. Epoxy is wonderful stuff and saves the knife maker a lot of trouble and work. Though the pins and such are nice to look at.

Recycling materials is more than half the fun for me. I get a real thrill out of it. I'll wear the label "Womble" proudly. Didn't know what they were until now.

Didn't know what they were until now.

Here is the video of the process I generally follow to make a smaller blade like this.

[video]https://youtu.be/ALSL-82ec6g[/video]

Here is a short video of my forge.

[video]https://youtu.be/BI9qz55Qv6s[/video]

Here are the plans for the forge burner. Easy to make and cheap. I did not make up these plans. I found them on the internet.

Have fun recycling!

Tom, we have lots of roadkill, and I hadn't thought of that. I'll have to take on that messy project!

Tony, I'll add a few thoughts.

I use a homemade coffee can propane forge most of the time. I have a proper coal forge, but I don't use it too much because fuel is hard to get and it's not as convenient. I'll post the plan for the forge I use and the link to a short video of it. I'll also post a video that I made going through the basic forging process I use.

I like to take my blade to very near its final edge. For heat treating I close the choke on the burner to get a reducing fire, which is really low pressure. This gives me lots of control, and I don't have any problem with a decarbonized surface on the edge. I normalize the blade three times and quench it three times in canola oil. A metallurgist told me it is almost the equivalent of the high price fast commercial heat treating oils.

For this one I cut some notches in the tang and just epoxied it into the handle. I am an avid carver, and I carve lots of hard wood. I've never had this system fail on me. I've destroyed a few knives on purpose to see how secure they were. It took some beating with a hammer just to get the handle off. Epoxy is wonderful stuff and saves the knife maker a lot of trouble and work. Though the pins and such are nice to look at.

Recycling materials is more than half the fun for me. I get a real thrill out of it. I'll wear the label "Womble" proudly.

Here is the video of the process I generally follow to make a smaller blade like this.

[video]https://youtu.be/ALSL-82ec6g[/video]

Here is a short video of my forge.

[video]https://youtu.be/BI9qz55Qv6s[/video]

Here are the plans for the forge burner. Easy to make and cheap. I did not make up these plans. I found them on the internet.

Have fun recycling!

Last edited:

I should add the dimensions of the highway knife. Overall length is 8 inches. Blade is 3 5/8 inches. Thickest part of the spine is about 3.5 mm. It tapers to a point. I have a semi flat, semi convex bevel. Trying to get the best of both worlds.

And here is the adze I used to rough out the handle. Very effective tool.

And here is the adze I used to rough out the handle. Very effective tool.

Last edited:

I should add the dimensions of the highway knife. Overall length is 8 inches. Blade is 3 5/8 inches. Thickest part of the spine is about 3.5 mm. It tapers to a point. I have a semi flat, semi convex bevel. Trying to get the best of both worlds.

And here is the adze I used to rough out the handle. Very effective tool.

Great work and that adze should be called the "ibis",

Similar threads

- Replies

- 17

- Views

- 575

- Replies

- 19

- Views

- 1K

- Replies

- 10

- Views

- 791