Helle use 12c27 stainless sandwiched between 304 or 18/8, and 01 sandwiched between mild steel. Helle knives are really good, and often the brand that Ray Mears has been know to gift

- 40 years in engineering, about 10 of those as an instrument maker actually making things, I used a lot of 01 lathe tool bits to machine a lot of very varied materials. I still find it works well enough for carving a few bits of wood and striking a ferro rod.

- I don't know what precise steels Helle use, but whatever it is my Eggen has superb edge retention. Pity it doesn't do the trick with the ferro rod though.

- The laminates used in the Frost/Mora 106 and 120 I also like a lot.

Your top 3 steels and why?

- Thread starter gra_farmer

- Start date

-

Hey Guest, Early bird pricing on the Summer Moot (21st July - 2nd August) available until March 31st, we'd love you to come. PLEASE CLICK HERE to early bird price and get more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

While I accept that some steels are definitely better for some applications the effect of processing and heat treatment are so large that generalizations of this type are somewhat meaningless. On some Am. boards a continuous reason for fights, over nothing really.

On the third hand one can easily state with good reason that some manufacturer/maker has succeeded on certain material/model.

On the third hand one can easily state with good reason that some manufacturer/maker has succeeded on certain material/model.

Thanks for that. The 304 outer would explain the poor performance with ferro rods, it's quite soft for a stainless.Helle use 12c27 stainless sandwiched between 304 or 18/8, and 01 sandwiched between mild steel. Helle knives are really good, and often the brand that Ray Mears has been know to gift

I agree that standardisation is difficult to draw conclusions, but thanks to friends lending mainly spydercos, 30 of the different steels trialled were the same brand....and mainly Delicas and PM2's.While I accept that some steels are definitely better for some applications the effect of processing and heat treatment are so large that generalizations of this type are somewhat meaningless. On some Am. boards a continuous reason for fights, over nothing really.

On the third hand one can easily state with good reason that some manufacturer/maker has succeeded on certain material/model.

Knifenerds articles are quite informative though not always covering quite everything - as he himself admits. I like his style of writing.

Revisiting this thread, I have been handling more of the mid range steels and have gotten a real application for 14c28n and 154cm.

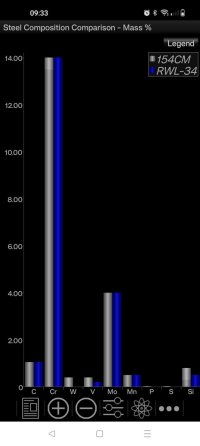

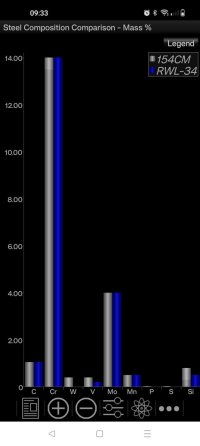

I am coming across more 154cm steel, for a steel that was first developed in the 1970's I am quite pleased with it. It is almost a completely the same as RWL34.

Reading around the forums, most compare 154cm as the stainless version of O1....in relation to edge retention I feel at a similar hardness 154cm is far better.

I am coming across more 154cm steel, for a steel that was first developed in the 1970's I am quite pleased with it. It is almost a completely the same as RWL34.

Reading around the forums, most compare 154cm as the stainless version of O1....in relation to edge retention I feel at a similar hardness 154cm is far better.

RWL is better as it is a powder steel ( actually so is CPM come to think of it, confused it with 154CM). Smaller/cleaner grain structure, looks like porcelain when heat treated correctly. Not used CPM to make something, but used it on other knives. I do prefer RWLRevisiting this thread, I have been handling more of the mid range steels and have gotten a real application for 14c28n and 154cm.

I am coming across more 154cm steel, for a steel that was first developed in the 1970's I am quite pleased with it. It is almost a completely the same as RWL34.

View attachment 82475

Reading around the forums, most compare 154cm as the stainless version of O1....in relation to edge retention I feel at a similar hardness 154cm is far better.

Last edited:

I think that I understand this interest in the various steels but have no understanding of the metallurgy. It’s something that has never crossed my mind before reading this thread. I do vaguely remember being told in the 70’s that a Puma knife was so hard it was unusable.

If my knife does what I ask of it that’s enough for me. It’s the task that matters.

Thinking back over this summer outdoors:- I’ve cut guyline, prepped and eaten food and shaved wood flakes for post-tinder. I’ve scraped a ferrocerium and a couple of fox pelts (both with the back edge) and done the odd bit of whittling. All with an Opinel. You can tell me what steel they use. I dunno.

Couple of swipes with a carborundum puck and carry on.

Genuine intrigue - do some of you folk select from or carry a range of different steel knives for the tasks you anticipate on a trip?

Now- I accept that I am talking about using knives.

You guys who forge knives are a different matter altogether. That’s magic and alchemy.

However I don’t know how to make bricks or what my house is actually made of. They’ve done their job for a hundred years and thus far, I’m happy.

This is an interesting thread, I shall look back and continue to read it. As I said, I’m intrigued but it’s not my world.

If my knife does what I ask of it that’s enough for me. It’s the task that matters.

Thinking back over this summer outdoors:- I’ve cut guyline, prepped and eaten food and shaved wood flakes for post-tinder. I’ve scraped a ferrocerium and a couple of fox pelts (both with the back edge) and done the odd bit of whittling. All with an Opinel. You can tell me what steel they use. I dunno.

This.^^^^^^^.The ones I kept were fully usable. Just had to sharpen them before each use.

I think that is what people had to do before the invention of modern steel production.

Couple of swipes with a carborundum puck and carry on.

Genuine intrigue - do some of you folk select from or carry a range of different steel knives for the tasks you anticipate on a trip?

Now- I accept that I am talking about using knives.

You guys who forge knives are a different matter altogether. That’s magic and alchemy.

However I don’t know how to make bricks or what my house is actually made of. They’ve done their job for a hundred years and thus far, I’m happy.

This is an interesting thread, I shall look back and continue to read it. As I said, I’m intrigued but it’s not my world.

Difficult to choose only three but here is my 3.

MagnaCut: Almost stain proof. Despite my best effort, I was not managed to put stain on it with normal use. Best edge retention and toughness balance given the stainless property. Great edge stability. Requires diamond/CBN to get best out of it. Prefer it on small to medium sized knives (sub 6 inches) at 62-64 HRC depending on the use.

AEBL: Decent corrosion resistance better than Magnacut for extremely fine edges or larger knives that would be used very toughly. Gets wicked edge easily with any decent stone. Prefer is 60-62 HRC depending on use.

CruWear: Get incredible edge offer the best combination of everything. As a bonus, it is a semi-stainless knife. Will require diamond/CBN for best edge results. Would shine at 61-62 for though use knife, but would be great at 63-64 as well for thin slicers.

MagnaCut: Almost stain proof. Despite my best effort, I was not managed to put stain on it with normal use. Best edge retention and toughness balance given the stainless property. Great edge stability. Requires diamond/CBN to get best out of it. Prefer it on small to medium sized knives (sub 6 inches) at 62-64 HRC depending on the use.

AEBL: Decent corrosion resistance better than Magnacut for extremely fine edges or larger knives that would be used very toughly. Gets wicked edge easily with any decent stone. Prefer is 60-62 HRC depending on use.

CruWear: Get incredible edge offer the best combination of everything. As a bonus, it is a semi-stainless knife. Will require diamond/CBN for best edge results. Would shine at 61-62 for though use knife, but would be great at 63-64 as well for thin slicers.

I’ve liked 14C28N done by QSP and Morakniv. Edge retention is good, so is its ease to get sharp again (both not too dissimilar to a well treated VG-10), corrosion resistance is very good but where it really excels is it’s stability and impact resistance even at low geometries. It does well at 59-60 HRC. A high performance none CPM steel.

I have continued my mission to try as many steels as possible, and been joining in on a few challenges on multi tool.org

What I am finding is that I am really enjoying the simple steels, with good heat treatments. I carried a SAK classic for a month, and didn't touch another knife the whole time. The same is for the current opinel challenge, and I am renewing a long lost bond.

So my revised list is as follows:

Stainless: M390 and X55CrMo14 (SAK stainless steel). However, I am often finding 154CM in rotation, it's a good low/mid range stainless steel that is very forgiving. I am yet to really trial 14c28n..... I'll look at what I have....

Toolsteel: Between CPM 3v and CPM M4/Vanadis 23 - mainly for fixed blades.

A recent purchase of a M4 folder is quite exciting, and need to review a tool steel in a folder.

Carbon Steel: 01 the favourite of all, but I am enjoying 1095 and 1075 in some pukkos, but often usually run too soft for my taste. The C70 in the carbon opinels has been fun to rediscover.

What I am finding is that I am really enjoying the simple steels, with good heat treatments. I carried a SAK classic for a month, and didn't touch another knife the whole time. The same is for the current opinel challenge, and I am renewing a long lost bond.

So my revised list is as follows:

Stainless: M390 and X55CrMo14 (SAK stainless steel). However, I am often finding 154CM in rotation, it's a good low/mid range stainless steel that is very forgiving. I am yet to really trial 14c28n..... I'll look at what I have....

Toolsteel: Between CPM 3v and CPM M4/Vanadis 23 - mainly for fixed blades.

A recent purchase of a M4 folder is quite exciting, and need to review a tool steel in a folder.

Carbon Steel: 01 the favourite of all, but I am enjoying 1095 and 1075 in some pukkos, but often usually run too soft for my taste. The C70 in the carbon opinels has been fun to rediscover.

I saw a YouTube clip where they “scienced” the heck out of the Damascus effect (self sharpening micro serrations). It is there, but it depends on the pattern and the combination of materials, but they did have a few really surprising outcomes. I’ll try and post a link here later.My 1095 izula performed different to the Damascus,the Damascus had a nice toothy edge which suited me more in some applications.

Similar threads

- Replies

- 27

- Views

- 1K

- Replies

- 2

- Views

- 718

- Replies

- 1

- Views

- 369

- Replies

- 1

- Views

- 411

- Replies

- 53

- Views

- 6K