Titanium is always worth adding! Very cool!

If its thin guage, it will lessen jthe amount of heat conducted to the fan cowling, and in theory make the stove produce gas at a more consistent rate, increase the amount of heat conducted to the pot and lessen the thermal mass of the stove.

I'm thinking about a paintable coating for the combustion chanmber. Ive researched zirconium basd refractory paints, but it they coast too much. I am thinking that a slurry of ground vermiculite, sawdust and fire cement may be easy to make up and test. I sauspect it will crack off, but may stick well to the mica paper. When I fitted the mica, I treated it like wall paper and made multiple slits. It was loose till it had done a couple of burns-it then stuck fast with the tar.

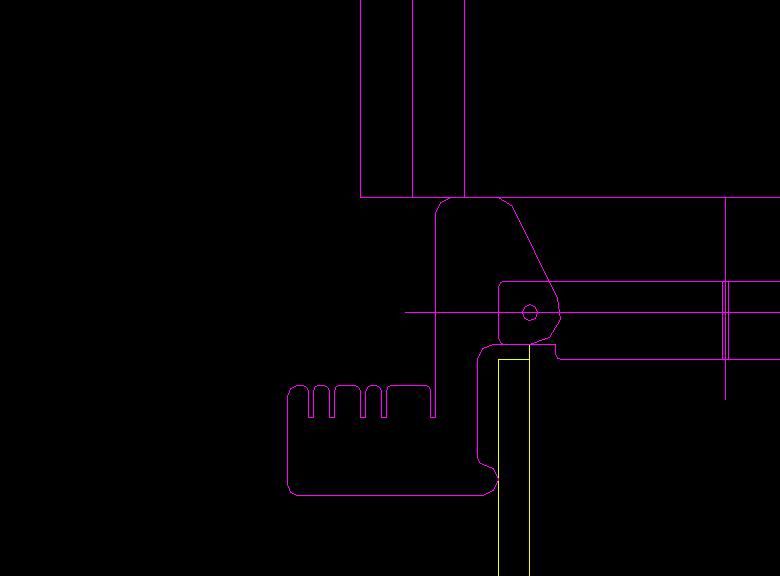

I'm looking forward to seeing what you come up with for the pot stand-the crossed stainless is a bit of a pain. Something that attaches permanetly to the outer wall would be better i think.

If its thin guage, it will lessen jthe amount of heat conducted to the fan cowling, and in theory make the stove produce gas at a more consistent rate, increase the amount of heat conducted to the pot and lessen the thermal mass of the stove.

I'm thinking about a paintable coating for the combustion chanmber. Ive researched zirconium basd refractory paints, but it they coast too much. I am thinking that a slurry of ground vermiculite, sawdust and fire cement may be easy to make up and test. I sauspect it will crack off, but may stick well to the mica paper. When I fitted the mica, I treated it like wall paper and made multiple slits. It was loose till it had done a couple of burns-it then stuck fast with the tar.

I'm looking forward to seeing what you come up with for the pot stand-the crossed stainless is a bit of a pain. Something that attaches permanetly to the outer wall would be better i think.