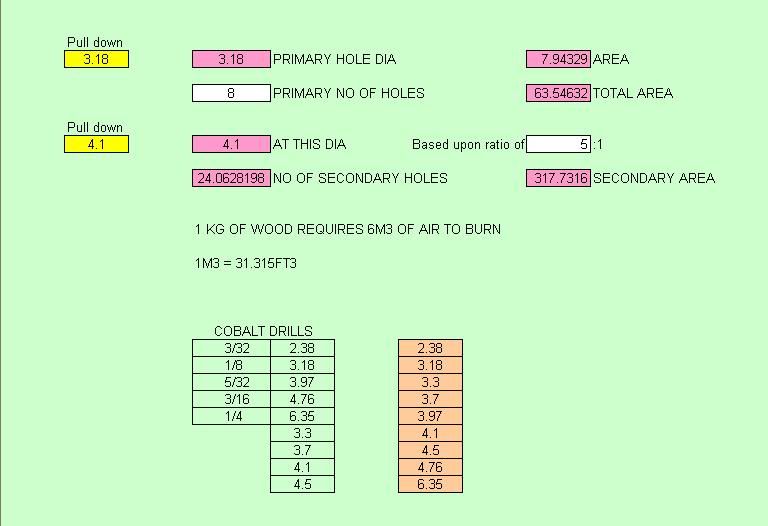

I think you'll find 6:1 is the stoichiometric ratio for wood,

That 6.1-1 ratio is mass, not volume-an easy error that had me flapping a bit

http://www.bioenergylists.org/stovesdoc/Anderson/GasifierLAMNET.pdf

It's in this doc, and quite a few others inc the tlud handbook.