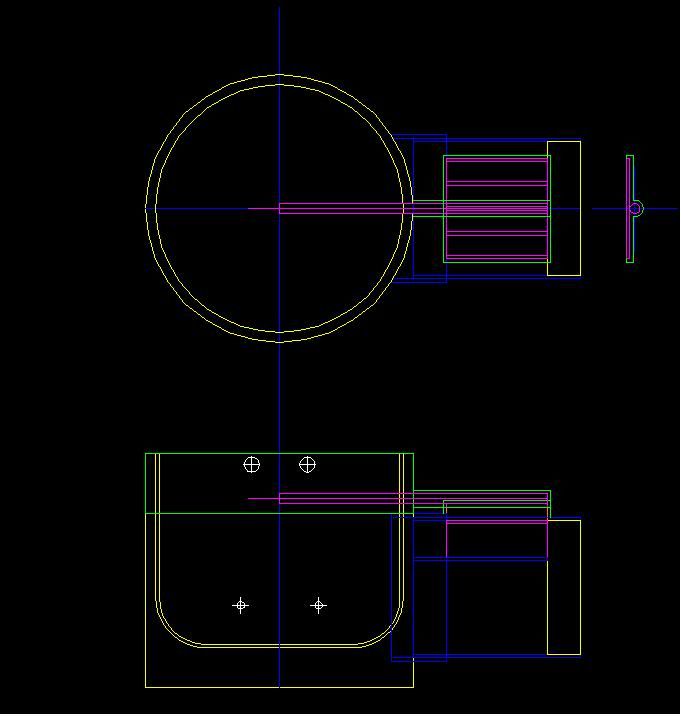

I had a chance to start on the TLUD this afternoon, its based on the 1L model so it will be bigger, the cup is 74 Dia by 60 tall. I used the datasheet to work out my primary and secondary, 10x 2.38 primary, 14x4.5 secondary which will give me slightly over 5:1.

I tried using the base as the outside and the cup holder, it worked but not after cutting away a lot of metal from the bottom, aren't Dremels wonderful.

Anyway, loose fitted the cup to the base, (after peening over the edge) and added two handfuls of wood pellets, wax and paper to start it, and sat the whole thing on top of my woodgas stove to add a fan source. Worked very well, no blue flames but a nice long burn. Next step the cut out and adding the fan, I need to order a couple of those Sunon fans, I'll use a 12v evercool I have until I get them.

I tried using the base as the outside and the cup holder, it worked but not after cutting away a lot of metal from the bottom, aren't Dremels wonderful.

Anyway, loose fitted the cup to the base, (after peening over the edge) and added two handfuls of wood pellets, wax and paper to start it, and sat the whole thing on top of my woodgas stove to add a fan source. Worked very well, no blue flames but a nice long burn. Next step the cut out and adding the fan, I need to order a couple of those Sunon fans, I'll use a 12v evercool I have until I get them.

races to £stretcher * .................."Fill my van with £2.99 flasks!"

races to £stretcher * .................."Fill my van with £2.99 flasks!"