Restoring a Mangle

- Thread starter British Red

- Start date

-

Come along to the amazing Summer Moot (21st July - 2nd August), a festival of bushcrafting and camping in a beautiful woodland PLEASE CLICK HERE for more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oh I had stuffed up the post above showing the "key" - so here it is - a little loose rectangle of steel that locks the cog onto the axle

Retaining key on cog / handle by British Red, on Flickr

Retaining key on cog / handle by British Red, on Flickr

Its a long old job - particularly when I lack all mechanical skill  Hopefully it'll get there in the end though!

Hopefully it'll get there in the end though!

Sorry to be an engineering pedant, but a woodruff key is semicircular shaped. A plain rectangular one as far as I recall doesn't have a specific name other than 'key'.A great "Lazarus" thread and an interesting read............I think the little key is properly known as a Woodruff key

I'll do a longer post when I have the time - but I got a finish coat of varnish on the table top today so I thought we would have our first "before and after" shot

Before

Mangle closed with lid down by British Red, on Flickr

After

IMG_1555 by British Red, on Flickr

On an allied subject, does anyone know the proper name for the thing at the bottom left in this picture?

Partially Stripped Cogs by British Red, on Flickr

Its a round collar with a grub screw that slides over a pivot to hold things in place. Feels like it should have a fancy term!

Before

Mangle closed with lid down by British Red, on Flickr

After

IMG_1555 by British Red, on Flickr

On an allied subject, does anyone know the proper name for the thing at the bottom left in this picture?

Partially Stripped Cogs by British Red, on Flickr

Its a round collar with a grub screw that slides over a pivot to hold things in place. Feels like it should have a fancy term!

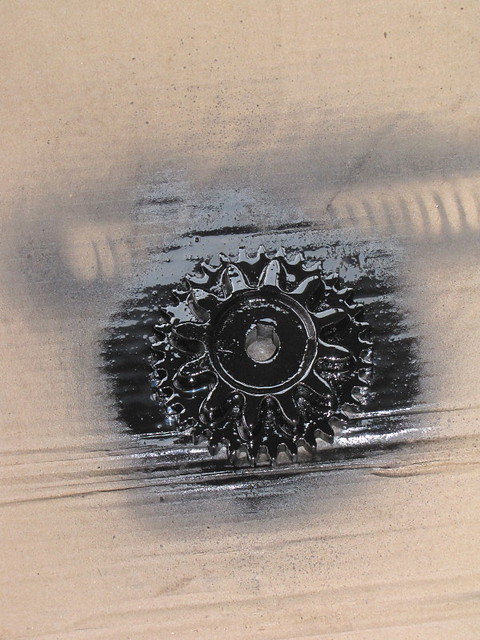

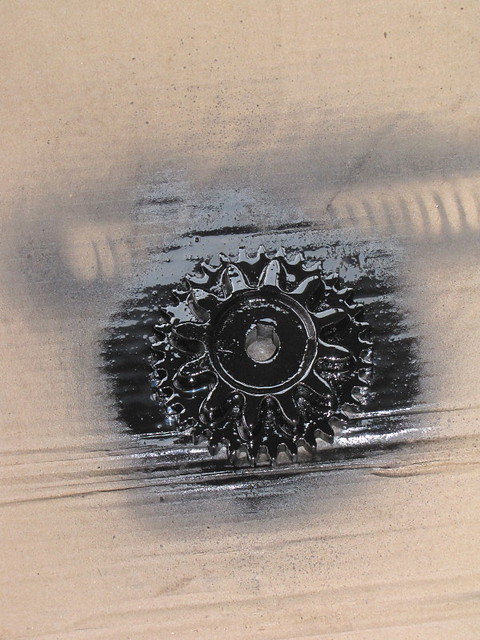

Well I started today off with completing the stripping of the parts I broke down earlier in the week and then got a first sprayed coat of metal paint on them

Sprayed Cog by British Red, on Flickr

Mangle wheel sprayed by British Red, on Flickr

I then hit a point where I needed to continue the disassembly. This meant breaking down the frame of the mangle. So I needed the big socket set

Socket set by British Red, on Flickr

Step 8 - Disassembling the Mangle Frame

Having got all smug about having the large sockets - it was inevitable that the first nut I tried to remove from the axle / pivot that allows the mangle to rotate beneath the table, I had no socket to fit

I do however have a very large adjustable spanner. I don't need it often - but I'm glad to have it when I do

Large adjustable spanner by British Red, on Flickr

Having been pleased with myself on that score, the nut on the other end of the pivot was completely siezed. I broke out the blow torch to loosen it - and was careful not to be smug. I'm not sure if it was burning paint, shifting rust or expanding the metal that released the nut, but release it did.

Heating siezed nut with blow torch by British Red, on Flickr

Remove nut holding mangle pivot axle by British Red, on Flickr

Having got the outer bolt off - I noticed there is also an inner nut

Spacer nut on mangle assembly pivot axle by British Red, on Flickr

Even with both nuts removed, I could not slide out the pivot - there were collars with grub screws at each end of the pivot preventing it from sliding in either direction. You can see the collar at the bottom right

Mangle assembly pivot axle by British Red, on Flickr

The grub screw had a weird square head - but fortunately a pair of mole grips released it

Retaining washer with grub screw loosened. by British Red, on Flickr

Even with the collars released, the axle was held in place by the end panels of the mangle frame. So I decided to remove the other bars holding the two sides together.

Cog retained by cotter pin by British Red, on Flickr

First I pulled the cotter pin and took off the upper cog

Cog removed by British Red, on Flickr

The "Oil" lubrication spot made me smile - its been a long time since this saw any oil!

Cog and cotter pin gone by British Red, on Flickr

Having removed that, I unbolted the catch that secures the mangle assembly and prevents it from turning down under the table

Unbolt mangle retaining catch by British Red, on Flickr

Having removed the catch, there was still a cross member holding the two sides together

Two nuts still in place by British Red, on Flickr

I unbolted this

Unbolt cross member by British Red, on Flickr

Then I took the big cast iron stretcher off the bottom

Unscrew coach bolts from stretcher by British Red, on Flickr

Stretcher removed from Mangle Frame by British Red, on Flickr

Only the pivot secured the two sides now. There was also a strannge bolt shown centrally locking the cog against the frame side

Coach bolt retaining cog and axle by British Red, on Flickr

I removed this

Remove Coach bolt securing cog on mangle assembly axle by British Red, on Flickr

I then found that this cog was actually threaded onto the axle - a vice was needed to remove it

Unscrew cog from axle by British Red, on Flickr

That removed the last of the small parts

Partially Stripped Cogs by British Red, on Flickr

and the large parts were fully broken down for stripping and re-finishing

Disassembled Mangle Frame by British Red, on Flickr

So there we are - the whole mangle is now broken down into the individual cast pieces. I will need to take a while now to strip, clean and re-finish each part. Then we can see if all these photos and notes helps me put it back together again

Sprayed Cog by British Red, on Flickr

Mangle wheel sprayed by British Red, on Flickr

I then hit a point where I needed to continue the disassembly. This meant breaking down the frame of the mangle. So I needed the big socket set

Socket set by British Red, on Flickr

Step 8 - Disassembling the Mangle Frame

Having got all smug about having the large sockets - it was inevitable that the first nut I tried to remove from the axle / pivot that allows the mangle to rotate beneath the table, I had no socket to fit

I do however have a very large adjustable spanner. I don't need it often - but I'm glad to have it when I do

Large adjustable spanner by British Red, on Flickr

Having been pleased with myself on that score, the nut on the other end of the pivot was completely siezed. I broke out the blow torch to loosen it - and was careful not to be smug. I'm not sure if it was burning paint, shifting rust or expanding the metal that released the nut, but release it did.

Heating siezed nut with blow torch by British Red, on Flickr

Remove nut holding mangle pivot axle by British Red, on Flickr

Having got the outer bolt off - I noticed there is also an inner nut

Spacer nut on mangle assembly pivot axle by British Red, on Flickr

Even with both nuts removed, I could not slide out the pivot - there were collars with grub screws at each end of the pivot preventing it from sliding in either direction. You can see the collar at the bottom right

Mangle assembly pivot axle by British Red, on Flickr

The grub screw had a weird square head - but fortunately a pair of mole grips released it

Retaining washer with grub screw loosened. by British Red, on Flickr

Even with the collars released, the axle was held in place by the end panels of the mangle frame. So I decided to remove the other bars holding the two sides together.

Cog retained by cotter pin by British Red, on Flickr

First I pulled the cotter pin and took off the upper cog

Cog removed by British Red, on Flickr

The "Oil" lubrication spot made me smile - its been a long time since this saw any oil!

Cog and cotter pin gone by British Red, on Flickr

Having removed that, I unbolted the catch that secures the mangle assembly and prevents it from turning down under the table

Unbolt mangle retaining catch by British Red, on Flickr

Having removed the catch, there was still a cross member holding the two sides together

Two nuts still in place by British Red, on Flickr

I unbolted this

Unbolt cross member by British Red, on Flickr

Then I took the big cast iron stretcher off the bottom

Unscrew coach bolts from stretcher by British Red, on Flickr

Stretcher removed from Mangle Frame by British Red, on Flickr

Only the pivot secured the two sides now. There was also a strannge bolt shown centrally locking the cog against the frame side

Coach bolt retaining cog and axle by British Red, on Flickr

I removed this

Remove Coach bolt securing cog on mangle assembly axle by British Red, on Flickr

I then found that this cog was actually threaded onto the axle - a vice was needed to remove it

Unscrew cog from axle by British Red, on Flickr

That removed the last of the small parts

Partially Stripped Cogs by British Red, on Flickr

and the large parts were fully broken down for stripping and re-finishing

Disassembled Mangle Frame by British Red, on Flickr

So there we are - the whole mangle is now broken down into the individual cast pieces. I will need to take a while now to strip, clean and re-finish each part. Then we can see if all these photos and notes helps me put it back together again

Just a quick post today - most of these posts are a "photographic map" so that I can remember how to reassemble the mangle. Given disassembly is now complete, I will be spending a good while stripping and re-finishing the major components. Each will go through a similar process to the smaller parts - paint strip, scrape, wire brush, spray

I did the stretcher today and some of the last of the smaller parts

Stretcher stripped of paint by British Red, on Flickr

First coat on stretcher by British Red, on Flickr

Each piece needs to be sprayed. left to dry, turned, repeated on the back. Then start again on the next coat. I won't bore people with that happening on every piece . I will show anything interesting like the re-finish on the rollers when I get to that and eventual re-assembly

. I will show anything interesting like the re-finish on the rollers when I get to that and eventual re-assembly

Red

I did the stretcher today and some of the last of the smaller parts

Stretcher stripped of paint by British Red, on Flickr

First coat on stretcher by British Red, on Flickr

Each piece needs to be sprayed. left to dry, turned, repeated on the back. Then start again on the next coat. I won't bore people with that happening on every piece

Red

Section 7 - Restoring the rollers

All the major parts have now been cleaned and repainted, so its time to address the rollers

There are a couple (literally) of woodworm holes

Woodworm in roller by British Red, on Flickr

So two coats of woodworm treatment before it goes any further

Woodworm treatment painted on by British Red, on Flickr

Then I filled the holes and ribbed down - notice how the paint came off?

Filler by British Red, on Flickr

After filling I applied a liberal coat of wood hardener to stabilise a couple of soft patches. Notice how shiny the wood is (the hardener is dry)

Wood Hardener by British Red, on Flickr

At this point I got all scientific. I wanted waterproofed grippy rollers. So one of these latex or rubber paints must be ideal

Latex Paint by British Red, on Flickr

On it goes - quite streaky and thin on the first coat

First Coat by British Red, on Flickr

Second coat will improve it no doubt

Second coat by British Red, on Flickr

Wrong!

I think either it could not adhere to the hard smooth rollers - or reacted with one of the many chemicals on them.

It had to go

Scraping Off by British Red, on Flickr

The rollers are now finished in a more traditional tough varnish

Varnish Rollers by British Red, on Flickr

Ahh well - something had to go wrong

All the major parts have now been cleaned and repainted, so its time to address the rollers

There are a couple (literally) of woodworm holes

Woodworm in roller by British Red, on Flickr

So two coats of woodworm treatment before it goes any further

Woodworm treatment painted on by British Red, on Flickr

Then I filled the holes and ribbed down - notice how the paint came off?

Filler by British Red, on Flickr

After filling I applied a liberal coat of wood hardener to stabilise a couple of soft patches. Notice how shiny the wood is (the hardener is dry)

Wood Hardener by British Red, on Flickr

At this point I got all scientific. I wanted waterproofed grippy rollers. So one of these latex or rubber paints must be ideal

Latex Paint by British Red, on Flickr

On it goes - quite streaky and thin on the first coat

First Coat by British Red, on Flickr

Second coat will improve it no doubt

Second coat by British Red, on Flickr

Wrong!

I think either it could not adhere to the hard smooth rollers - or reacted with one of the many chemicals on them.

It had to go

Scraping Off by British Red, on Flickr

The rollers are now finished in a more traditional tough varnish

Varnish Rollers by British Red, on Flickr

Ahh well - something had to go wrong

Section 8 - Restoring the Fasteners

Having done all the hard work of cleaning and stripping and grinding and spraying and painting and sanding and varnishing....

I really didn't want to put the mangle back together with these

Rusty fastenings by British Red, on Flickr

I probably could get imperial sized replacements, but the metal is sound - just surface rust. So out with an abrasive wheel

Abrasive Wheel in drill press by British Red, on Flickr

They cleaned up quite well

Cleaned bolt by British Red, on Flickr

A quick spray to ensure they don't rust again

Spraying fasteners by British Red, on Flickr

The screws though, I'm not prepared to put back - the heads and threads are too far gone. I have measured them

Micrometer measuring screw by British Red, on Flickr

and will replace with correctly sized imperial screws -

Having done all the hard work of cleaning and stripping and grinding and spraying and painting and sanding and varnishing....

I really didn't want to put the mangle back together with these

Rusty fastenings by British Red, on Flickr

I probably could get imperial sized replacements, but the metal is sound - just surface rust. So out with an abrasive wheel

Abrasive Wheel in drill press by British Red, on Flickr

They cleaned up quite well

Cleaned bolt by British Red, on Flickr

A quick spray to ensure they don't rust again

Spraying fasteners by British Red, on Flickr

The screws though, I'm not prepared to put back - the heads and threads are too far gone. I have measured them

Micrometer measuring screw by British Red, on Flickr

and will replace with correctly sized imperial screws -

...and is finished

Completed Mangle as table by British Red, on Flickr

Completed Mangle by British Red, on Flickr

Completed Mangle in Laundry Mode by British Red, on Flickr

Completed Mangle as table by British Red, on Flickr

Completed Mangle by British Red, on Flickr

Completed Mangle in Laundry Mode by British Red, on Flickr

Similar threads

- Replies

- 12

- Views

- 389

- Replies

- 7

- Views

- 221

- Replies

- 7

- Views

- 572

- Replies

- 8

- Views

- 339

- Replies

- 2

- Views

- 146