Right, lets assume you have your bevel filed right...just make sure it is right!

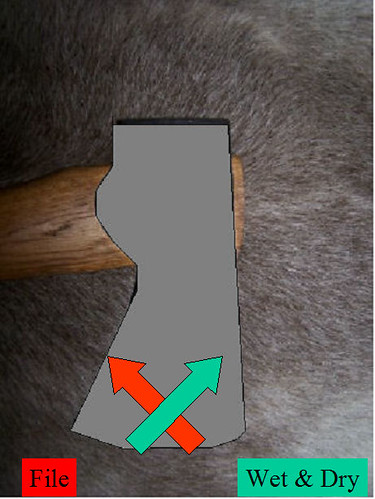

Now, the next stage is to use your coarsest wet and dry paper to smooth the bevel out. Start with nothing finer than about 240 grit. We need to change direction (whilst still removing metal from bit to poll). You therefore change the angle to 90 degrees from your original angle and are filing bit to poll, heel to toe - like this.

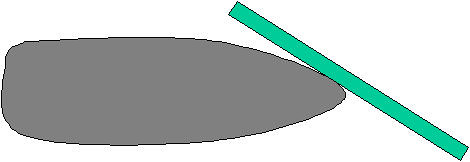

You need to use your coarsest grade until you have sanded out all the file marks - this will take some time. I use a diamond file before switching down, but you are limited in tools and this will work fine - it'll just take a bit longer. You do have a problem though. If you wrap your wet and dry over something flat, you will make contact on a tiny area - like this

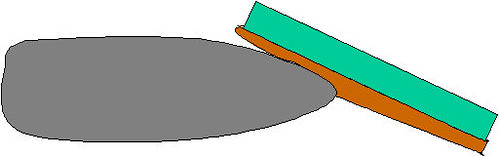

This means that it will take ages to do and will tend to sand the convex bevel flat, however much you "roll your wrist". What you need to do is put something soft between your board and the wet and dry and then push down as you push back. This will bring a lot of wet and dry into contact with the bit and will also preserve the convexing. It will look more like this

How I achieved this into a handy package is as follows.

I took two bits of credit card sized thick plastic and glued them together just in the middle - it looked like this

I stock a bit of mousemat on top with glue (thick leather or anything "spongy" will do

I cut the wet and dry to size and stuck the ends between the boards

This is how it looks

Now you dont need to make this - a bit of wood, some felt and some sticky tape will do, but you get the idea!

You need to change wet and dry as it wears down and keep going until

all the file marks in the original direction are gone.

When this is done, change to 400 grit and switch back to the first direction until all the lines from the 240 grit have gone. Then change direction and switch to 600 grit until the 400 grit lines have gone.

Then stick some more photos on!

Red

. We all give advice all though - thats what the site is all about surely

. We all give advice all though - thats what the site is all about surely