Hi this is my restoration thread on restoring and tweaking this axe

it's been a long time coming for me to be able to find the time to get it done due to one thing or another but it's done now.

Here's a link to the backstory http://www.bushcraftuk.com/forum/showthread.php?t=124832&p=1557719#post1557719

Ill apologise now for the many bad pictures

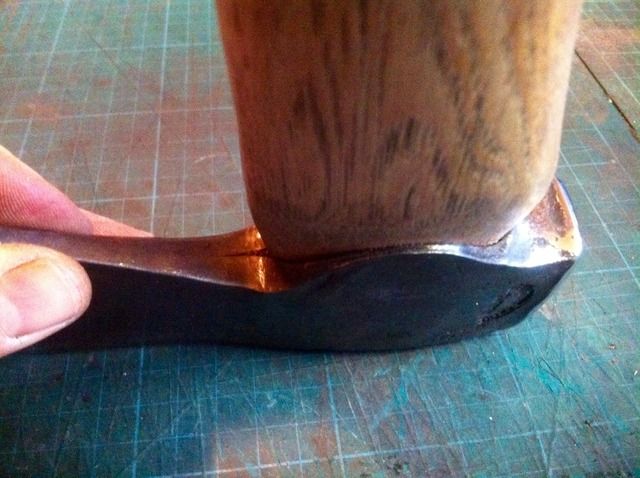

First job was to saw off the old knackered handle near to the head

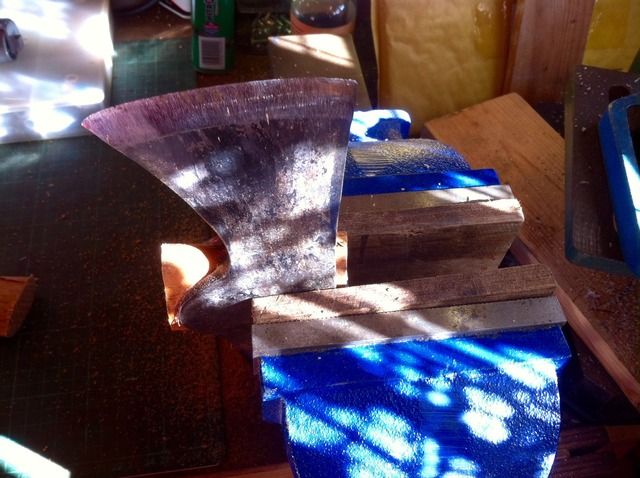

job done if you notice I use scrap wood as soft jaws for my vice saves chewing up things

next step swap vices this ones for my pillar drill time to drill the wedge out

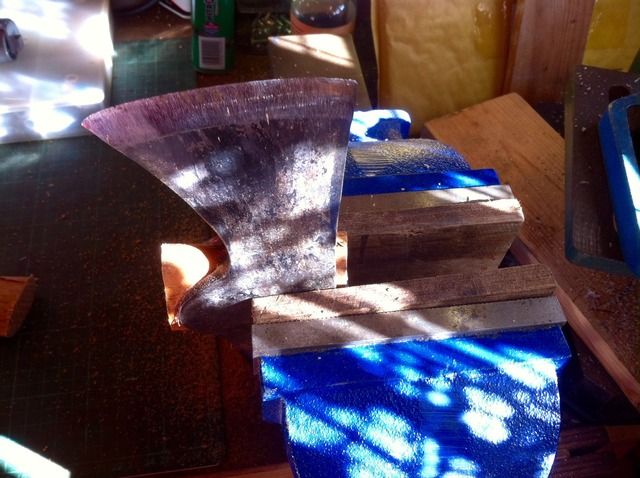

time to persuade the metal wedge to come out I had mislaid my rubber mallet so improvised

it's been a long time coming for me to be able to find the time to get it done due to one thing or another but it's done now.

Here's a link to the backstory http://www.bushcraftuk.com/forum/showthread.php?t=124832&p=1557719#post1557719

Ill apologise now for the many bad pictures

First job was to saw off the old knackered handle near to the head

job done if you notice I use scrap wood as soft jaws for my vice saves chewing up things

next step swap vices this ones for my pillar drill time to drill the wedge out

time to persuade the metal wedge to come out I had mislaid my rubber mallet so improvised