Just a quick question for the Knife makers on here.

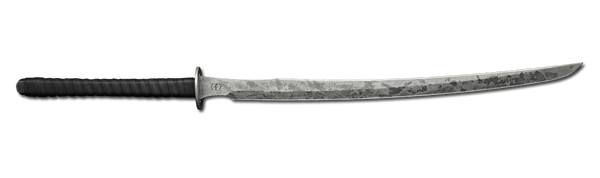

Is making a longer blade more difficult than a shorter one IE Does making a long Sword like blade pose different issues ( in a metallurgical ) sense than a short knife style blade , or is it purely an issue of dimensions and equipment - not many ovens I guess will take a long sword length of material.

I'm asking as I'd like a Sword ( for weird fantastical reasons... ) but I don't know if its anything I can get a maker from this forum to make or if I need to look elsewhere.

Is making a longer blade more difficult than a shorter one IE Does making a long Sword like blade pose different issues ( in a metallurgical ) sense than a short knife style blade , or is it purely an issue of dimensions and equipment - not many ovens I guess will take a long sword length of material.

I'm asking as I'd like a Sword ( for weird fantastical reasons... ) but I don't know if its anything I can get a maker from this forum to make or if I need to look elsewhere.