I like Hammocks.

- Thread starter No Idea

- Start date

-

Come along to the amazing Summer Moot (21st July - 2nd August), a festival of bushcrafting and camping in a beautiful woodland PLEASE CLICK HERE for more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bad day.

Just went and got 6 sheets of 6mm 8 x 4 marine ply.

I was paying £18 inc for 9mm, but today they put the price up.

They charged me £20 per sheet + vat, £140 in all for the 6mm.

They said they have put the price of 9mm marine up to £25 a sheet.

This is going to seriously limit our building this coming year.

Does anyone know anywhere cheaper?

Just went and got 6 sheets of 6mm 8 x 4 marine ply.

I was paying £18 inc for 9mm, but today they put the price up.

They charged me £20 per sheet + vat, £140 in all for the 6mm.

They said they have put the price of 9mm marine up to £25 a sheet.

This is going to seriously limit our building this coming year.

Does anyone know anywhere cheaper?

Last edited:

Bad day.

Just went and got 6 sheets of 6mm 8 x 4 marine ply.

I was paying £18 inc for 9mm, but today they put the price up. They charged me £20 per sheet + vat, £140 in all.

THey said they have put the price of 9mm marine up to £25 a sheet.

This is going to seriously limit our building this coming year.

Does anyone know anywhere cheaper?

What makes normal ply into marine ply?

Is there a finishing process you can do to normal ply yourself?

Hi Bushwhacker

I wish!

The difference is apparently in the glue they use to bind the layers of wood together, the quality of those layers and no voids.

When they make the sheets, there are gaps between the strips of wood they lay down to press into the sheets. These gaps will soak up water and blow the board apart. In marine ply these voids as they are called are filled.

Because of the sharpness of the curves in the front of some hulls, the ply would actually crack if you bent it to shape as is.

You can build a steamer, which is simply a box with a steam source leading into it, which you leave the ply in for up to one hour before bending to fit the hull. When the sheet cools, it actually settles to shape and stays there. A marine ply sheet must be of good enough quality to take that hour.

You can see this has been used in the backs of some plywood chairs.

Also, for at least one of the projects Im involved with, the timber has to be passed to the British Standard for Marine ply for the boat to be accepted. It needs about 10 sheets of 9mm. A £120 price hike is a hell of a lot to absorb.

I wish!

The difference is apparently in the glue they use to bind the layers of wood together, the quality of those layers and no voids.

When they make the sheets, there are gaps between the strips of wood they lay down to press into the sheets. These gaps will soak up water and blow the board apart. In marine ply these voids as they are called are filled.

Because of the sharpness of the curves in the front of some hulls, the ply would actually crack if you bent it to shape as is.

You can build a steamer, which is simply a box with a steam source leading into it, which you leave the ply in for up to one hour before bending to fit the hull. When the sheet cools, it actually settles to shape and stays there. A marine ply sheet must be of good enough quality to take that hour.

You can see this has been used in the backs of some plywood chairs.

Also, for at least one of the projects Im involved with, the timber has to be passed to the British Standard for Marine ply for the boat to be accepted. It needs about 10 sheets of 9mm. A £120 price hike is a hell of a lot to absorb.

Last edited:

It just reminded me of the time when a company I worked for made a standard product but these same products also went for AQD (Aviation quality) the only difference being the paper trail that went with the part (accountability). Same part, more paperwork.

If you need marine grade stainless steel shackles and screws, it really pays to buy them by the stainless steel code from a fastener stockist, rather than from a chandlery as its usually well under half price.

Normal outside quality ply and marine ply are very different beasts though, unfortunately.

Normal outside quality ply and marine ply are very different beasts though, unfortunately.

It had tried to snow.

Several times, but hadnt really put its back into it.

It definitely had the temperature low enough though.

We had a few hours to kill, nowhere to go and nothing to do....

Well, nothing we really wanted to do...

Except eat and sleep, of course...

Several times, but hadnt really put its back into it.

It definitely had the temperature low enough though.

We had a few hours to kill, nowhere to go and nothing to do....

Well, nothing we really wanted to do...

Except eat and sleep, of course...

Thought about clearing an area of leaves.

Discovered they were frozen solid like bits of plastic and decided they wernt that likely to burst into flames without something specatcular and left them alone.

Found a little branch of twigs, thinner than my little finger, well, a lot thinner as my little finger isnt that thin.

Found a log for the hobo to sit on nice and close to some hammock trees ive used before...

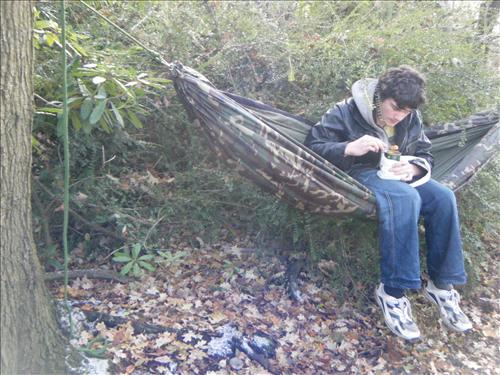

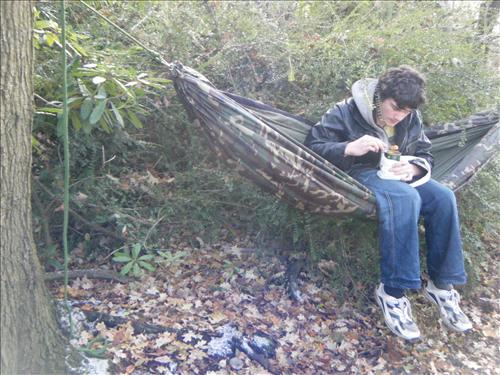

Just got set up and biggest kid nicked the warm spot!

Discovered they were frozen solid like bits of plastic and decided they wernt that likely to burst into flames without something specatcular and left them alone.

Found a little branch of twigs, thinner than my little finger, well, a lot thinner as my little finger isnt that thin.

Found a log for the hobo to sit on nice and close to some hammock trees ive used before...

Just got set up and biggest kid nicked the warm spot!

I like it here.

He nearly let it go out

I had thought of producing a culinary masterpiece...

...and gave up.

How come he managed to grab the first one and leg it?

I always pass the first one on.

Need to learn something from him

...or teach him some manners.

He nearly let it go out

I had thought of producing a culinary masterpiece...

...and gave up.

How come he managed to grab the first one and leg it?

I always pass the first one on.

Need to learn something from him

...or teach him some manners.

Last edited:

Now my tins is on, the fire has practically gone out.

Pigging kid.

Still, I suppose there are worse places to wait for lunch to cook

Im pretty sure its died.

How come his hammock suddenly shot up and mine almost ended up on the ground as soon as I sat in it?

On second thoughts...dont answer that.

Still.....

Making sure I conserve energy so I dont pass out from hunger while it cooks.

Yep

Pretty sure its out.

Oooh! Sunshine!

Not sure but I think they are silver birch...

I need some more bark.

Pigging kid.

Still, I suppose there are worse places to wait for lunch to cook

Im pretty sure its died.

How come his hammock suddenly shot up and mine almost ended up on the ground as soon as I sat in it?

On second thoughts...dont answer that.

Still.....

Making sure I conserve energy so I dont pass out from hunger while it cooks.

Yep

Pretty sure its out.

Oooh! Sunshine!

Not sure but I think they are silver birch...

I need some more bark.

This place is well below freezing - even though its 2.30 pm.

Hmmm....

Wonder if I can nick his...

I like it here.

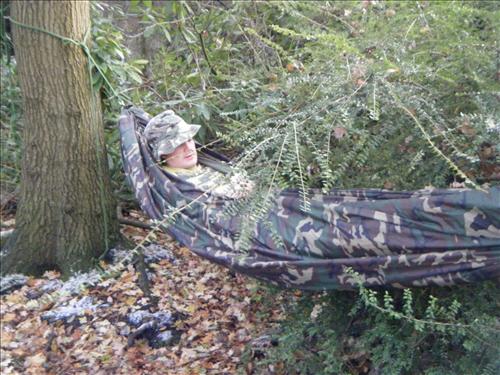

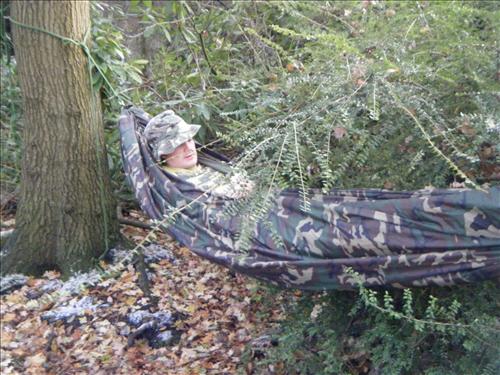

My kid got creative with this shot....

lol

He managed to hang his hammock in a privvet bush

You can tell its - 3C.

Thats why he took his coat off.

Too hot.

Hmmm....

Wonder if I can nick his...

I like it here.

My kid got creative with this shot....

lol

He managed to hang his hammock in a privvet bush

You can tell its - 3C.

Thats why he took his coat off.

Too hot.

Listening to all the birds and watching the squirrels

Wsnt quick enough with the camera though.

Fire site all packed up ready to go.

We disturbed a few leaves and took off a little of the frost and ice, but other than that...

No sign we were there.

Just as it should be.

Wsnt quick enough with the camera though.

Fire site all packed up ready to go.

We disturbed a few leaves and took off a little of the frost and ice, but other than that...

No sign we were there.

Just as it should be.

evening chap. i've got a feeling that now-a-days, there is no difference between marine ply and standard ply ( not shuttering ply ) may be worth checking specs if you can.

As for price, have you thought about setting up a trade account with a local builders merchant, you get a bit of discount when you do that. ( you don't need to be a builder to set up an account ) Could also be useful if you need to buy tools or work wear etc.

Robbi

As for price, have you thought about setting up a trade account with a local builders merchant, you get a bit of discount when you do that. ( you don't need to be a builder to set up an account ) Could also be useful if you need to buy tools or work wear etc.

Robbi

Have you subscribed to the song of the paddle? Maybe the guys over there are able to come up with a cheaper alternative that you can use or a cheaper supplier.

Good Luck, sorry I cant help you there

Ness

Good Luck, sorry I cant help you there

Ness

Thank you Friend Robbi

Will investigate them on Monday..

My kids just managed to surprise me.

Doesnt happen very often.

Seems they have used all the cutlery, sooooo.....

They are using jaffa cakes as spoons to eat pot noodles.

Will investigate them on Monday..

My kids just managed to surprise me.

Doesnt happen very often.

Seems they have used all the cutlery, sooooo.....

They are using jaffa cakes as spoons to eat pot noodles.

Similar threads

- Replies

- 2

- Views

- 404