I would like to share with you the evolution of my "Bushknife".

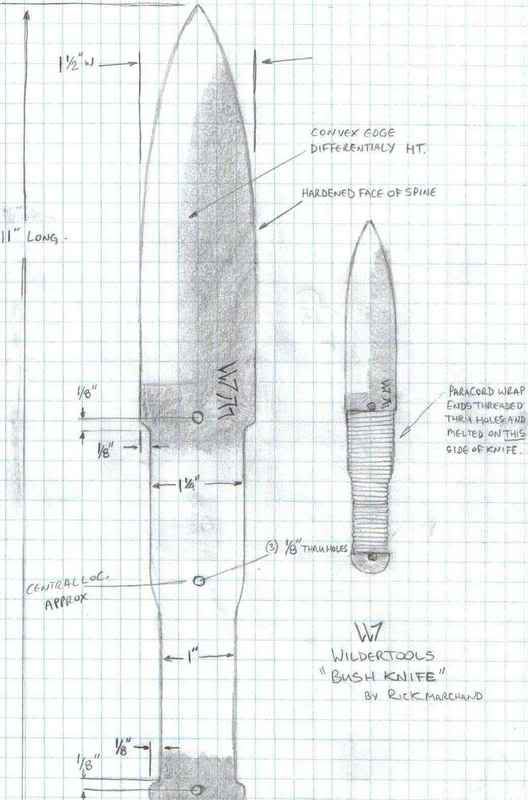

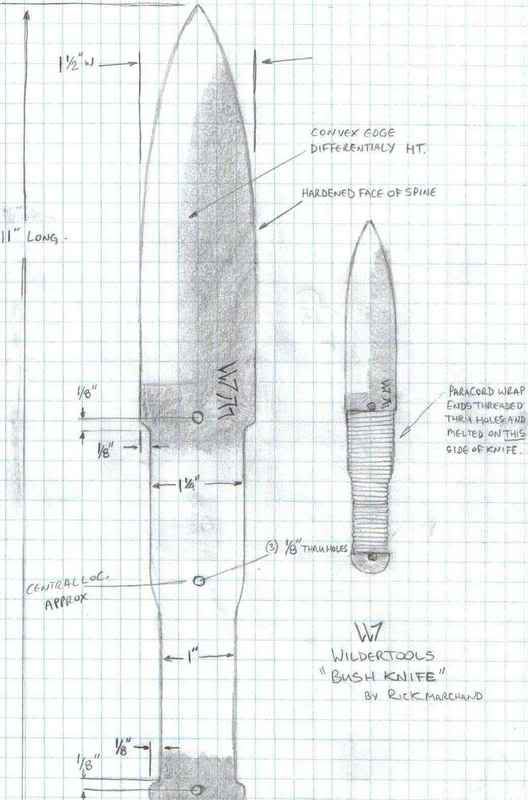

The descision to make my own Bushknife started out as a few drawings. I wanted it to be a little beafy but not too clunky. Eventually, I cut out a blank to get the feel for the knife...

Unhappy with the flow of the knife I decided to blend the lines in and make it more organic. It was at this point that I made the descision to go with a cord wrapped handle. This was going to be a survival knife and I wanted every component to have multiple uses. It was going to be my carver, chopper, prybar, digger, thrower and striker for traditional "flint and steel".

My first intention was to harden the spine of the knife for use with flint and steel... but because it needed to te strong and flexible I had to change my design and incorporate the striker into the butt of the handle. This way I could fully draw back the hardness on the spine to make it felxible and tough as nails. The cord wrap was slipping after heavy use and a few throws and since glueing would render the cord useless for survival scenarios... It was back to the drawing board....

I made a handle channel for the wrap to seat itself and get locked into position. I also included a palm swell toward the front of the handle to improve grip. The ends of the cord would be fed through the holes and melted in place. With the help of Master Bladesmith and new found friend, Wally Hayes, I forged the knife and began what I hope to be the final design for the Buskknife..... we'll see.

Here are some pics of the sheath I made for the knife... After lots of measuring, cutting, dyeing, glueing, sewing and riveting... I totally SCREWED IT UP when I applied the hot wax dip ... Yes.... I had the mixture WAY to hot and the sheath shriveled up like a raisin ... You learn from your mistakes... That was the first time that ever happened to me.... snif, snif.

So here I am now... knife heat treated and ready for finish grinding... NEW improved sheath made (totally riveted) including a successful hot dip... whew...

Here is a pic with the handle wrapped... the residue in between the windings is beeswax... I soaked the handle in melted beeswax to improve grip in wet conditions and it helps keep your hand from chaffing during heavy use. I put it through some tests yesterday... carving, chopping, splitting, scraping, prying, and flint and steel firestarting.... I like it.

Rick

The descision to make my own Bushknife started out as a few drawings. I wanted it to be a little beafy but not too clunky. Eventually, I cut out a blank to get the feel for the knife...

Unhappy with the flow of the knife I decided to blend the lines in and make it more organic. It was at this point that I made the descision to go with a cord wrapped handle. This was going to be a survival knife and I wanted every component to have multiple uses. It was going to be my carver, chopper, prybar, digger, thrower and striker for traditional "flint and steel".

My first intention was to harden the spine of the knife for use with flint and steel... but because it needed to te strong and flexible I had to change my design and incorporate the striker into the butt of the handle. This way I could fully draw back the hardness on the spine to make it felxible and tough as nails. The cord wrap was slipping after heavy use and a few throws and since glueing would render the cord useless for survival scenarios... It was back to the drawing board....

I made a handle channel for the wrap to seat itself and get locked into position. I also included a palm swell toward the front of the handle to improve grip. The ends of the cord would be fed through the holes and melted in place. With the help of Master Bladesmith and new found friend, Wally Hayes, I forged the knife and began what I hope to be the final design for the Buskknife..... we'll see.

Here are some pics of the sheath I made for the knife... After lots of measuring, cutting, dyeing, glueing, sewing and riveting... I totally SCREWED IT UP when I applied the hot wax dip ... Yes.... I had the mixture WAY to hot and the sheath shriveled up like a raisin ... You learn from your mistakes... That was the first time that ever happened to me.... snif, snif.

So here I am now... knife heat treated and ready for finish grinding... NEW improved sheath made (totally riveted) including a successful hot dip... whew...

Here is a pic with the handle wrapped... the residue in between the windings is beeswax... I soaked the handle in melted beeswax to improve grip in wet conditions and it helps keep your hand from chaffing during heavy use. I put it through some tests yesterday... carving, chopping, splitting, scraping, prying, and flint and steel firestarting.... I like it.

Rick