If I was to change the handle on something like an Opinel cos it didn't suit me I'd have to change the blade steel as well.

The other half - Handles.

- Thread starter Pattree

- Start date

-

Come along to the amazing Summer Moot (21st July - 2nd August), a festival of bushcrafting and camping in a beautiful woodland PLEASE CLICK HERE for more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Putting a bit of oil on a wooden handle isn’t really maintenance, nobody mentioned resin. Regarding steel, any carbon steel will start to oxidise after a while, and there are specialist products to protect blades in storage.Nope.

At least not since 1966. The drawer isn’t damp but then I find the idea of using resin because the knife is badly stored a bit odd.

Edited to add:

Weren’t the blades rusty as hell in an environment that rotted wood?

Many knife makers are very well experienced with what works in terms of handle shape for a particular knife and its intended usage, hence the coke bottle shape on most bushcraft knives. Most knives are not hard use, or intended for all day use, so handle shape is of little importance.

No, I wouldn’t have bought that knife.But do you adapt or change the shape of a handle that didn’t suit you?

This is interesting, thanks for the response.

To me, the blade is the working tool. It simply performs a range of functions in a specific way. Many of you are happy to change a blade shape or grind to suit the knife function. Some of you require complex steels to cut whatever it is that you cut. I understand that. My needs are different from yours. I can do everything that I require of a knife with a simple mass produced Sandvic stainless steel blade. Our requirements are individual; our blades perform to our requirements.

So much for blades.

Are handles different?

To me, the handle is much more personal. It is the tool holder and the bridge between me and the tool. Off the shelf is fine if I use it for a few minutes at a time but wherever it is practical I would still want to create something just for me. Is a symmetrical cross section always a good idea? I can’t do much with the plastic handle of my Explore but my other #12’s allow me to make my knives personal.

I an truly surprised that I seem to be alone.

To me, the blade is the working tool. It simply performs a range of functions in a specific way. Many of you are happy to change a blade shape or grind to suit the knife function. Some of you require complex steels to cut whatever it is that you cut. I understand that. My needs are different from yours. I can do everything that I require of a knife with a simple mass produced Sandvic stainless steel blade. Our requirements are individual; our blades perform to our requirements.

So much for blades.

Are handles different?

To me, the handle is much more personal. It is the tool holder and the bridge between me and the tool. Off the shelf is fine if I use it for a few minutes at a time but wherever it is practical I would still want to create something just for me. Is a symmetrical cross section always a good idea? I can’t do much with the plastic handle of my Explore but my other #12’s allow me to make my knives personal.

I an truly surprised that I seem to be alone.

Last edited:

Think the only handle mods i have ever done was to remove the finger guard on a Hultafors HVK and old style Mora 511 as I found they got in the way for the tasks i was performing (i like to choke up on the blade when carving).

Generally and as mentioned above in Nice65's post, the manufacturers, be that a stand alone maker or a mass manufacturer like Mora or Hults know what does and doesn't work and in 99.99% of daily use, the handles they produce are perfectly fine, certainly bar the above cases mentioned, i can't think of where i have ever modified a handle on any tool or felt the need to do so.

Generally and as mentioned above in Nice65's post, the manufacturers, be that a stand alone maker or a mass manufacturer like Mora or Hults know what does and doesn't work and in 99.99% of daily use, the handles they produce are perfectly fine, certainly bar the above cases mentioned, i can't think of where i have ever modified a handle on any tool or felt the need to do so.

So:

A question for knife makers:

Are you ever commissioned to make a knife?

If so, do you ever tailor that knife to customer requirements?

Do you always create a symmetrical cross section?

This last item is something I’ve thought about for years and am (slowly) coming back to!

A question for knife makers:

Are you ever commissioned to make a knife?

If so, do you ever tailor that knife to customer requirements?

Do you always create a symmetrical cross section?

This last item is something I’ve thought about for years and am (slowly) coming back to!

Yes.So:

A question for knife makers:

Are you ever commissioned to make a knife?

If so, do you ever tailor that knife to customer requirements?

Do you always create a symmetrical cross section?

This last item is something I’ve thought about for years and am (slowly) coming back to!

Yes - that's the point of a commission

Not always but most of the time.

My DIY project back in 2009 - a bushcraft blade from recycled vintage sawblade. The wooden handle had been put on at the time, but after having been stored in the garden shed for 10++ years, the wood had gone bad with the damp, disintegrated from the blade and fallen off.

Will just wrap around para cord, and give some clean and light sharpening for reusing. It is very handy blade for prying, digging, shaving and cutting. Not good at chopping.

Will just wrap around para cord, and give some clean and light sharpening for reusing. It is very handy blade for prying, digging, shaving and cutting. Not good at chopping.

Last edited:

Thanks for asking. Gave me the opportunity to (kind of unsuccessfully) clean up a couple of these Spydercos. The Ironwood Delica is in the middle. Unfortunately, I gave it a wipe of teak oil, and that has rather hidden the pattern in the wood a bit; at least for now. I think these must be all the same vintage, around 2009-2010.I’d like to see a Desert Ironwood Delica.

Nice. That Urban looks great for being used, and it’s been an age since I saw the Danish Pen Knife. Sal Glesser really did everyone proud with his company’s knives didn’t he? You just had to ask, present some numbers and a sound design, and he’d make them.Thanks for asking. Gave me the opportunity to (kind of unsuccessfully) clean up a couple of these Spydercos. The Ironwood Delica is in the middle. Unfortunately, I gave it a wipe of teak oil, and that has rather hidden the pattern in the wood a bit; at least for now. I think these must be all the same vintage, around 2009-2010.

First, I think that a good handle is as important as a good blade. Having said that, one of my favorite blades is a Terava puukko 80 (or mini puukko as it was called when I bought it), in the bare tang version, and I kept it that way...- What do you look for in the handle of your knife?

- How important is it when you are purchasing?

- Do you modify knife handles?

- Pic?

I prefer a handle to be relative simple without too many deep finger choils, knobs and whatnot. Tangs, for me, are better hidden in the handle than visible (think electrocution or in winter, freezing your hands to the steel). Oval cross section if possible, so I can feel how I'm holding the knife, unlike with a pure cylinder shape. Not too skinny as I have fairly large hands (XL+, long fingers). Doesn't have to be wood or a 'noble' material like micarta, for everyday work knives hard plastic or rubber is fine. A handle should not hurt my hand when I use the knife for a long time or when I need to grip it firmly, and OTOH should let me hold it in a three-finger grip for quick chopping flicks (more important with a larger knife that could actually be used for chopping, but even with a lightweight blade one can wrist-flick through say green bramble vines hanging over a trail).

I have modified several handles on knives or machetes in my modest arsenal - like the handle on my Tramontina bolo, the one on my Skrama 240 (I hated the knob that separates the two grip positions, it hurt my hand so I got rid of it), the too-agressive ribs on the hard rubber handle of a Peltonen Ranger, and a full replacement of the very cheapo plastic handle scales on an old no-name surplus machete, with beech wood scales that made it useable again after many years. So yes, I sometimes do modify handles as I do blades/grinds. All that within reason.

Pic... have not tried that yet, not a full membership.

Tramhandle_strip01 by Frank Schweppe, on Flickr

Tramhandle_strip01 by Frank Schweppe, on FlickrOK, works... modified Tramontina handle. Rounded off, tang flushed with the scales, lanyard hole added. Very comfortable now, I can work with it for hours on end without any hotspots.

As an aside, in the whole package, sheaths are also important. At least the one provided by the manufacturer should hold the blade in and protect it, as well as protect the wearer from the blade. It does not have to be beautiful, just functional. An otherwise good knife with a very bad sheath makes an unattractive package.

I’m working on a handle for one of my knives, really to make it useable for me.

Why do knife makers almost universally make small knives with small handles? Whether I’m using a little Opinel #8 or my usual #12 I’m using the same sized hand to operate it!

Why do knife makers almost universally make small knives with small handles? Whether I’m using a little Opinel #8 or my usual #12 I’m using the same sized hand to operate it!

I am with you on this. I prefer wood and I can’t remember ever maintaining the wood handle on my main knife. Short of wiping it on my coat or something. I can’t remember what wood it is, but it’s dark and fine grained, it was just a block in my brothers (cabinet maker) off cut pile that I pinched. Might be walnut.Nope.

At least not since 1966. The drawer isn’t damp but then I find the idea of using resin because the knife is badly stored a bit odd.

Edited to add:

Weren’t the blades rusty as hell in an environment that rotted wood?

It's quite easy to put new scales on a SAK, I made a post about mine some years ago. In retrospect I would have used micarta, but the wood lover in me got the upper hand.Sorry for double post but this is a totally different question:

How possible might it be to put scales on a Swiss Army Knife that are double the thickness of the off the shelf versions?

I’ve done it with a Big Swede but they just bolt on.

- crosslandkelly

- Replies: 30

- Forum: DIY and Traditional crafts

That’s a great job. It’s neat and looks much more comfortable.

I think that wood was a good choice, particularly that wood. It gives the tool a more alive look.

I think that wood was a good choice, particularly that wood. It gives the tool a more alive look.

PRESENTING:

Please may I have a note for the wife to explain why I didn’t tidy up the drive and spent the afternoon in my workroom.

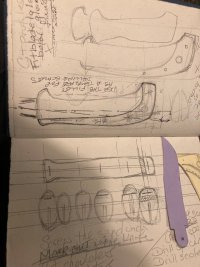

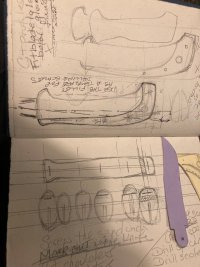

This is just a plywood mock up of a knife handle that I shall probably make in oak.

There are no prizes for guessing the inspiration for the handle shape.

I have two damaged fingers on my working hand. This shape helps the grip on both push and pull strokes.

It started with a lot of pencil sucking.

My intention was just to rough it out to see if a sandwich construction would work. (Opinels are usually a single piece of wood with a slot cut in the front. I have not been successful making the slot neatly.)

Then I got carried away and started to shape the handle. Ridiculous as it will probably end up in the skip. Birch ply is far too soft for a tool handle.

This is getting picture heavy.

Part two to follow.

THE ENORMOUS TURNIP.

First: @FerlasDave

Please may I have a note for the wife to explain why I didn’t tidy up the drive and spent the afternoon in my workroom.

This is just a plywood mock up of a knife handle that I shall probably make in oak.

There are no prizes for guessing the inspiration for the handle shape.

I have two damaged fingers on my working hand. This shape helps the grip on both push and pull strokes.

It started with a lot of pencil sucking.

My intention was just to rough it out to see if a sandwich construction would work. (Opinels are usually a single piece of wood with a slot cut in the front. I have not been successful making the slot neatly.)

Then I got carried away and started to shape the handle. Ridiculous as it will probably end up in the skip. Birch ply is far too soft for a tool handle.

This is getting picture heavy.

Part two to follow.

THE ENORMOUS TURNIP part 2.

After a lot of filing and sanding I got a shape that works for me. This is the raw wood. The blade and lock fitted after a few life lessons.

Then it got two coats of tea.

That wasn’t too bad but then I had to go and experiment with enonising.

Now it looks dirty, maybe sooty or a bit burned.

So now the blade and lock go back onto the Opinel #12 pullsaw handle that they live on.

So what did I learn.

Patience!

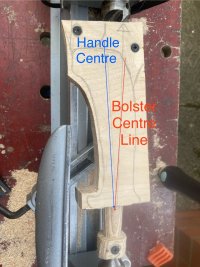

That the Viroblock (steel bolster and locking swivel) is too long for this style of knife. It’s like an extended ricasso.

I have also learned enough confidence that I may make my own lock with a unique engineering advantage.

That there are a number of asymmetries in the Opinel design:

The bolster isn’t in line with the handle:

This drops the point of the blade and presents the edge to its work optimally.

The pivot pin for the blade is forward of the diameter of the bolster by a millimetre. It has quite an effect further along the blade. I think this is to move the blade forward so that the nail-nick can be accessed when the knife is closed. They did this in 2000 when they introduced stainless steel and a lock that held the blade closed.

My handle encloses the blade completely as was the original design. (but still locks closed)

So what now?

A break from handle making while I think.

I’m keen to attempt my own swivel lock.

I might, just might make a blade from another tool blade.

Ahhhhh! Home sweet home!

pee ess.

Dunno what happened to the font.

No I haven’t but I’ve tried a Dremel and a router and I’m not very happy with it.Very nice.

Do you have an oscillating multi tool? That could be useful for cutting the slot…

I rather like this laminated construction. I may go for an ebonised oak handle with a brass spine/spacer.

Similar threads

- Replies

- 27

- Views

- 2K