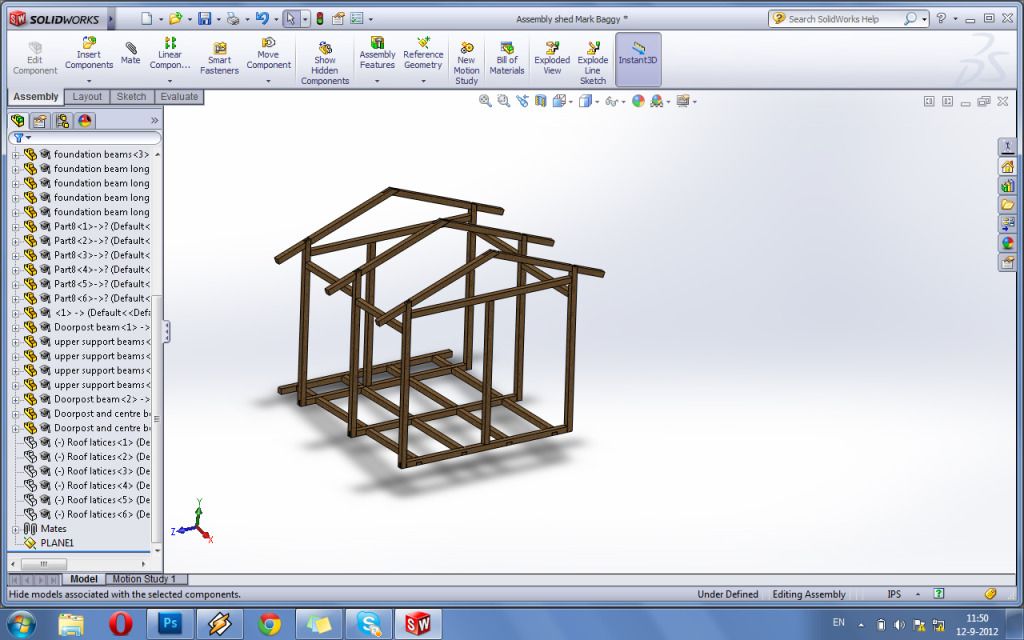

This is the Shed I designed for Mark Baigent, ( God I hope I write this correctly) by many more commonly known as Baggy

The Shed is 8 feet wide as requested and a little over 8 feet long the plan might you wanna build the shed are available, just send me a pm, and here as some snap shots of the frame.

it is constructed of 9 different types of beams, and can be secured either by screws or if you'dd want by simple peg connections, but enough talk lets show some pictures

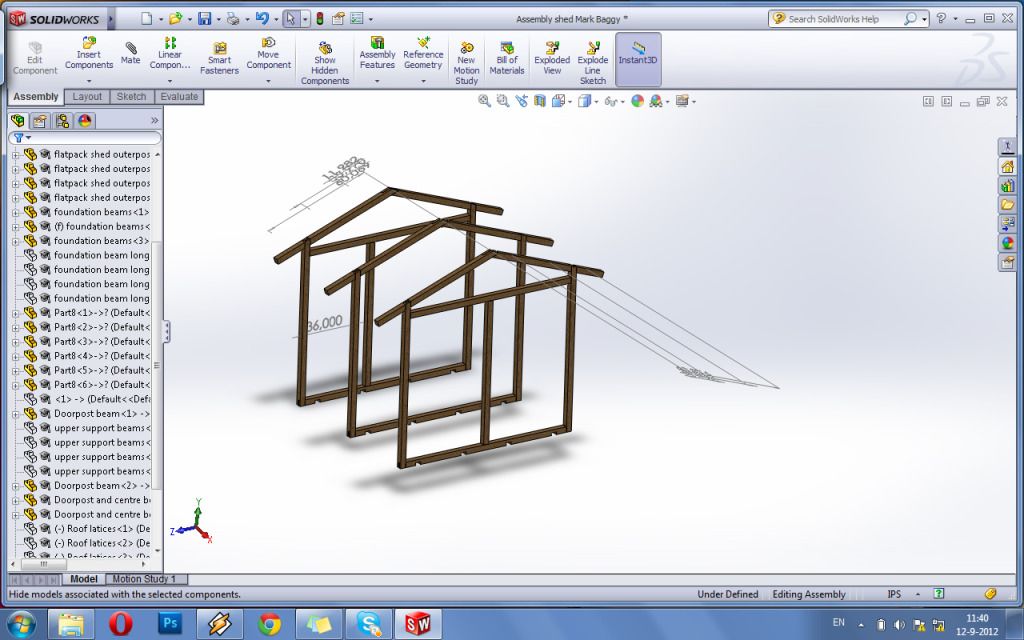

Here are the 5 steps of slotting the frame together.

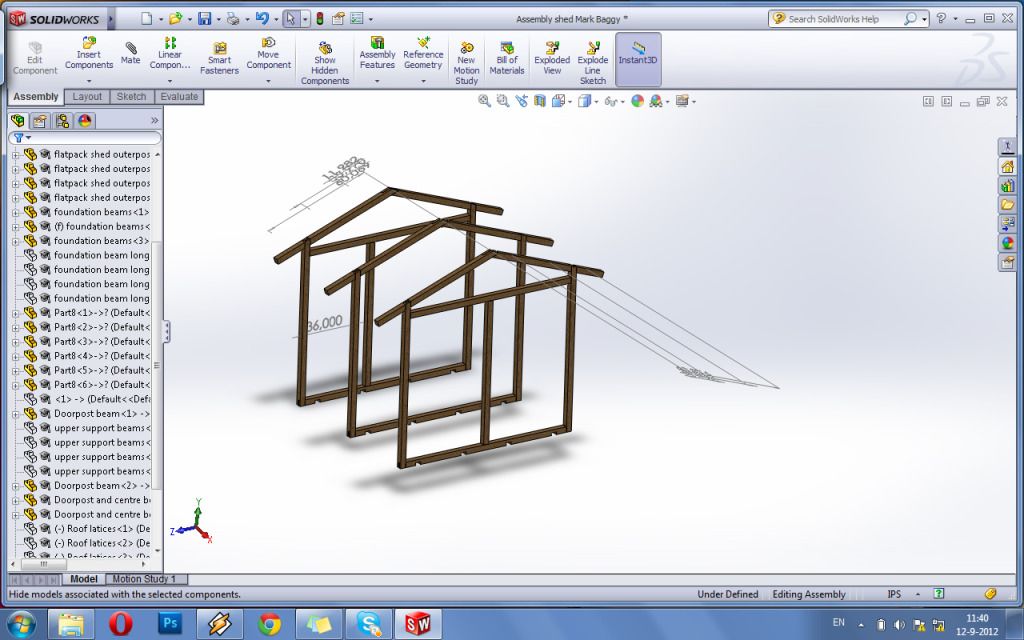

Step one: create the 3 house shaped frame pieces

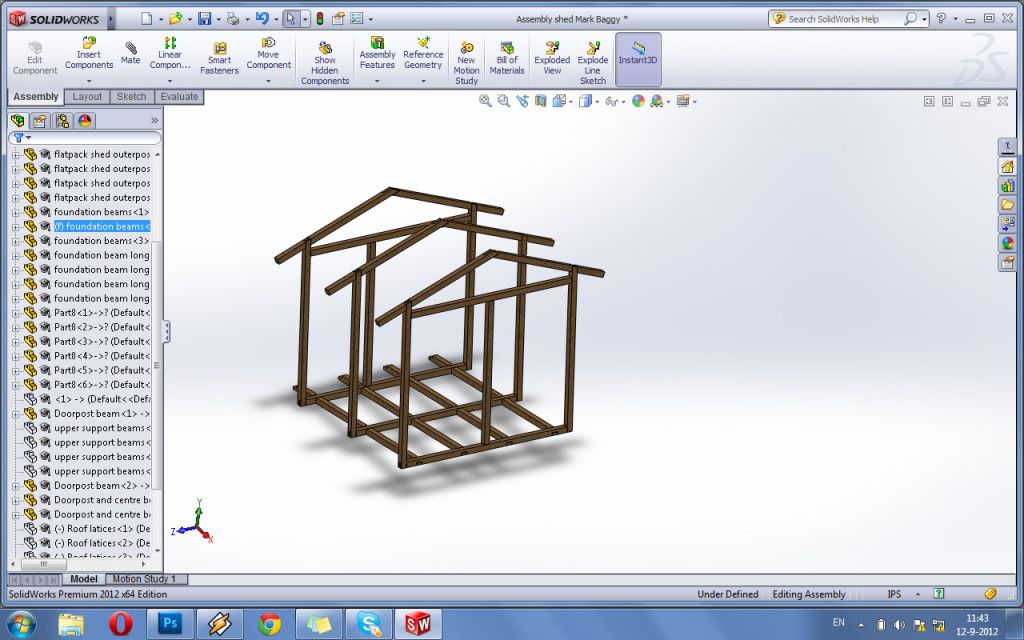

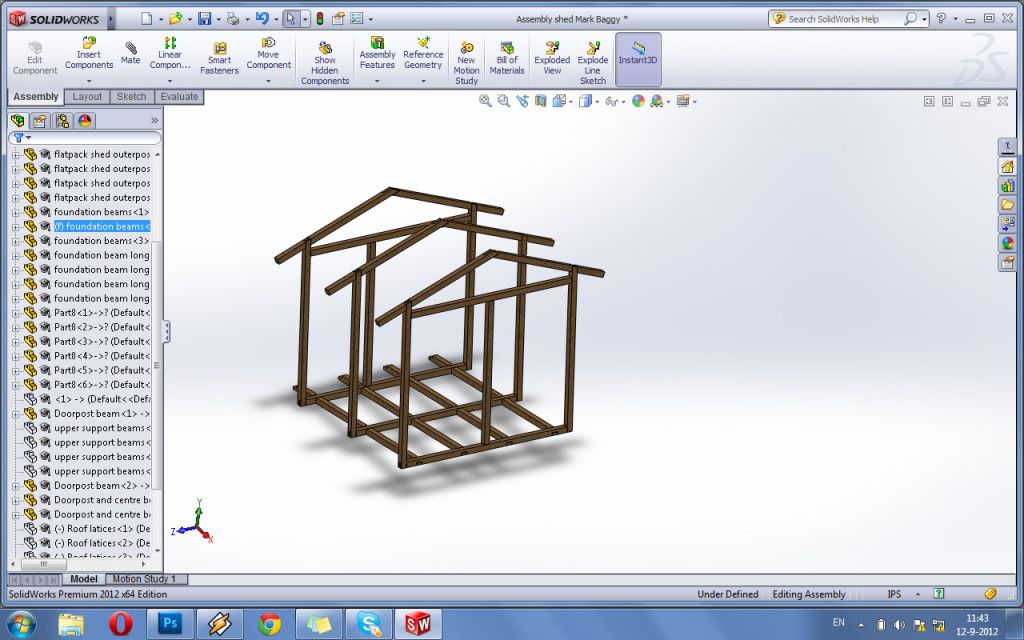

Step two: secure the foundation beams

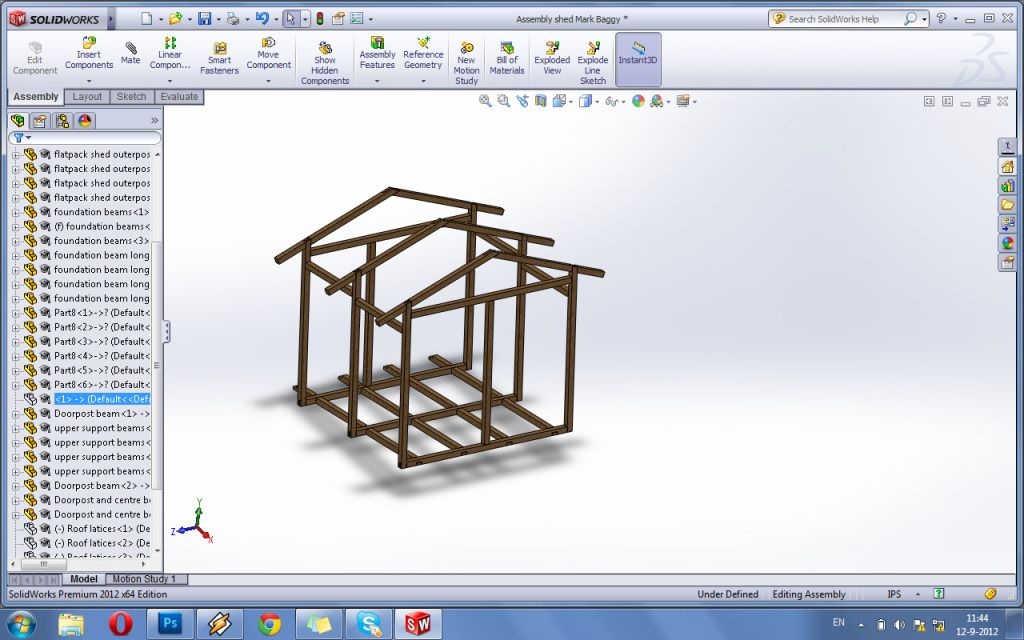

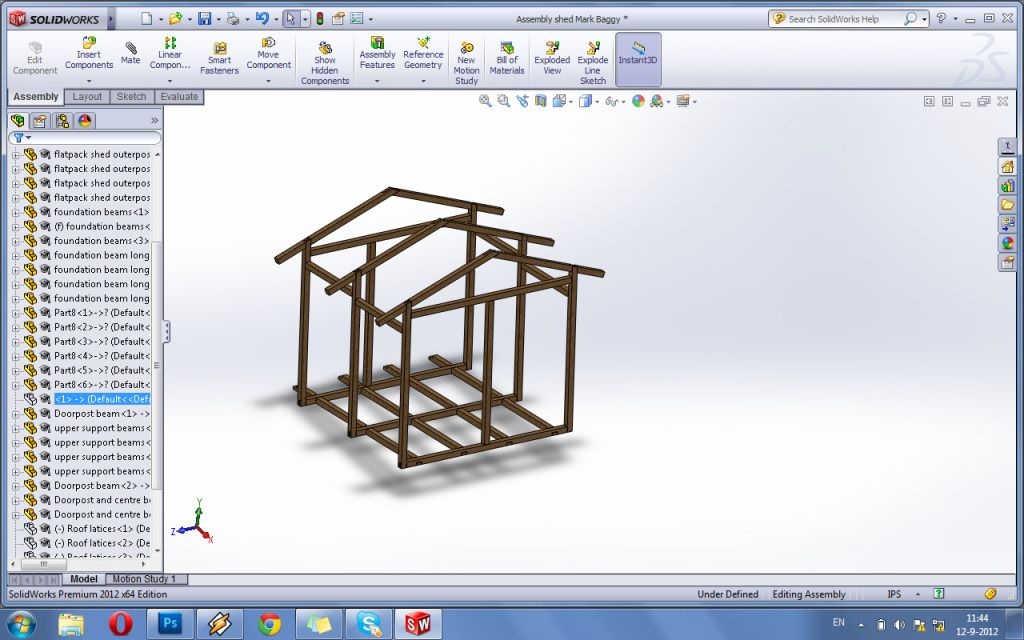

Step three: Secure the upper support beams

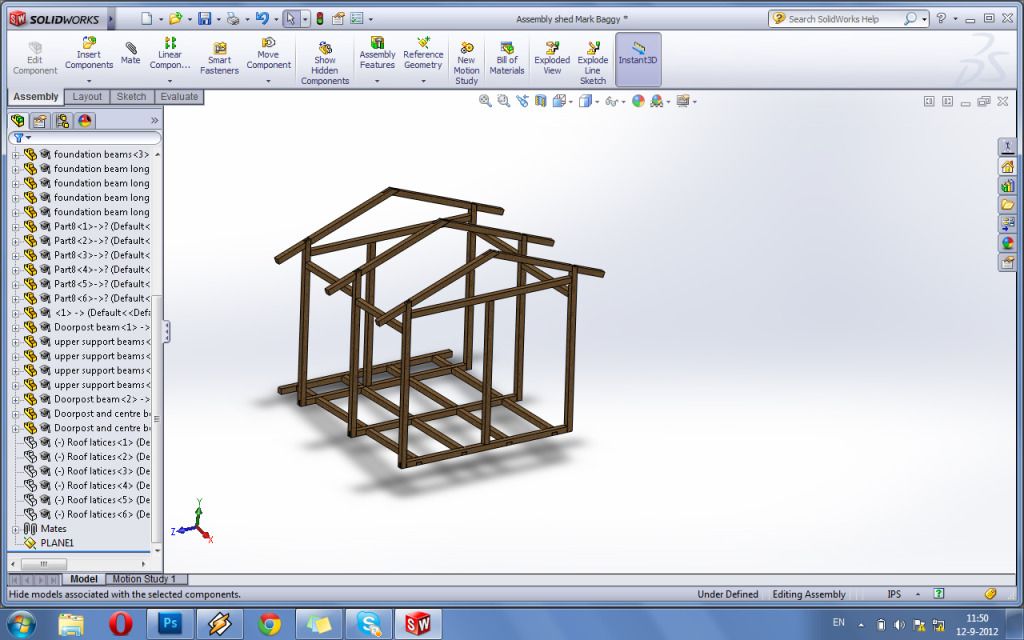

Step four: Add the End beam for the porch

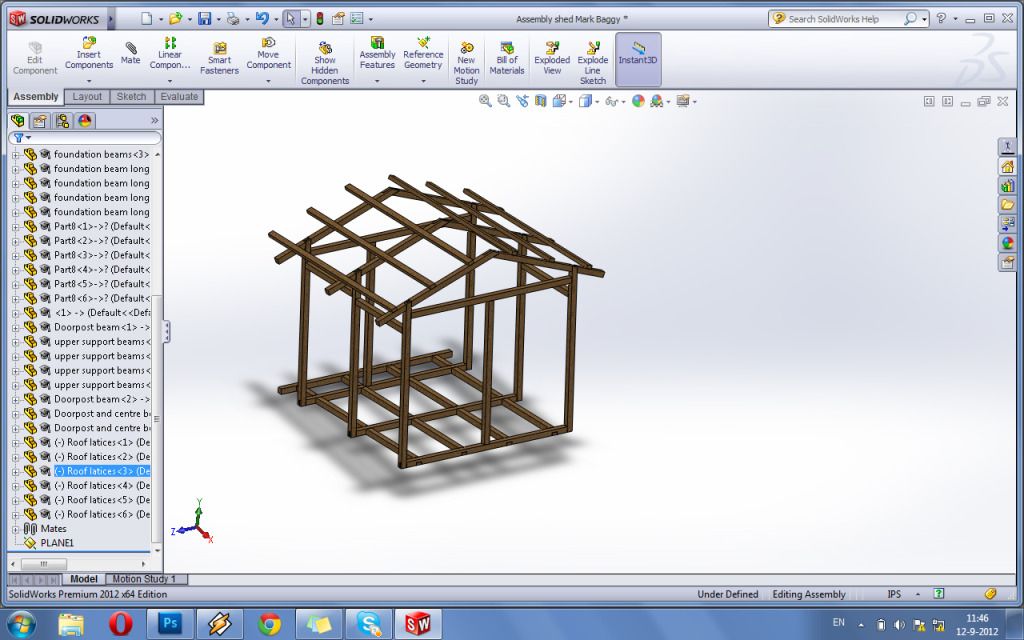

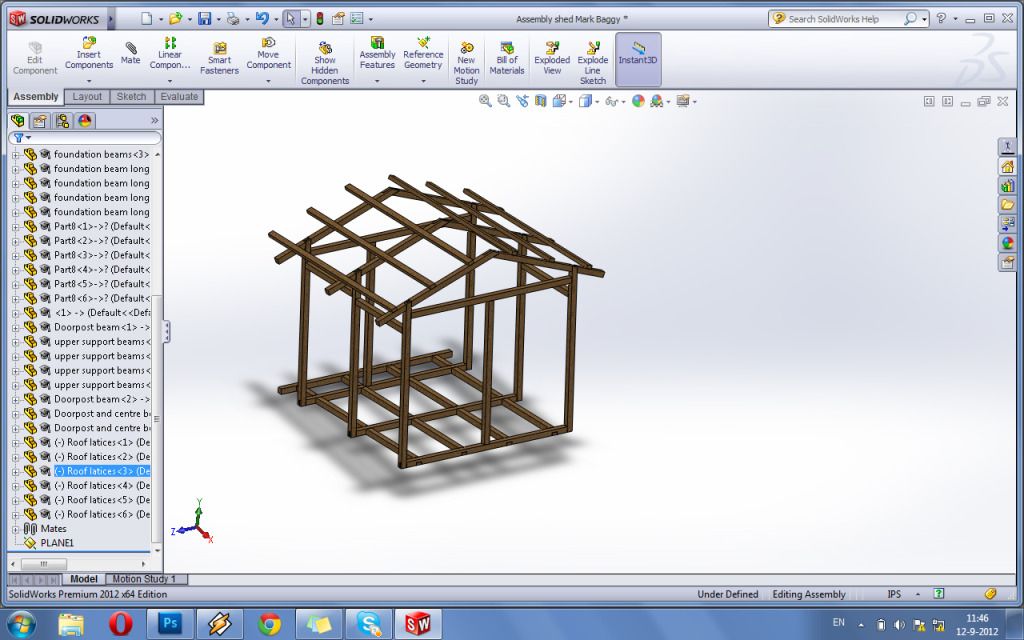

And Step 5: Add the Roof latices

and all you have to do now is add some cladding and some flooring

Yours sincerely Ruud

The Shed is 8 feet wide as requested and a little over 8 feet long the plan might you wanna build the shed are available, just send me a pm, and here as some snap shots of the frame.

it is constructed of 9 different types of beams, and can be secured either by screws or if you'dd want by simple peg connections, but enough talk lets show some pictures

Here are the 5 steps of slotting the frame together.

Step one: create the 3 house shaped frame pieces

Step two: secure the foundation beams

Step three: Secure the upper support beams

Step four: Add the End beam for the porch

And Step 5: Add the Roof latices

and all you have to do now is add some cladding and some flooring

Yours sincerely Ruud

Last edited: