Designing a Shed

- Thread starter grey-array

- Start date

-

Hey Guest, Early bird pricing on the Summer Moot (29th July - 10th August) available until April 6th, we'd love you to come. PLEASE CLICK HERE to early bird price and get more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hey Guys,

Wow what a massive response let me recollect myself ^^

Dear demographic,

I see exactly what you mean now, and yes I had thought about it but figured it to being a wee 4 by 4 feet shed it wouldnt need additional cross bracing,

but then again I'm only 20 springs young with zero knowledgeable people around me if it comes to anything wood, so have to figure that out on my own, I figured it to be strong enough and didn't think it would shift that much seeing the shed would be a semi open shed, as the left side of the shed was going to be clad so that there would be an inch gap between each board, this was an Idea of Baggy to have more air displacement in the shed to dry firewood and such. the humidity, and because of this open system the humidity would be the same outside as inside, which is usually the factor that makes most structures shift their shapes I figured it to be no problem, but then again experience is one of the best teachers so thanks for sharing that knowledge with me. might you ever want to talk some experience into me, my skype name is wcblokhoudertje.

Dear Lee,

I would be happy to help you with the design, and feel honored that you ask

yet I might have to put it on hold for a few weeks, as the coming 6 weeks are rushhour with my school

but after that I'd gladly do the deeds.

Dear sir Fish

The program

I'm using is indeed Solidworks 2012, which I'm used to, being a Industrial product Design student, and though not free software it is easily accessible through the torrent site of pirates ^^, a great ISO on there, which was a dream to install, Thank you SolidSquad ( the team that made free access possible)

Dear Roy,

Yeah cladding in sheet speeds up the process, but what also is the thing with multiplex is it doesnt shrink as it´s grain is turned 90 degrees each sheet, and held to gether with glue, this makes it almost un-hygroscopic meaning it is not affected by humidity. and in this case one side could be clad in that manner but the other because of the planned gaps is not.

And then here we go Mousey, prepare for thee answers ^^

Yes it does have a little porch, which could accommodate your more often used tools for easy access or perhaps a nice chair ^^

No windows but that is mainly because of the one inch gaps on the left wall of the shed and the rather large Door opening, which will not accommodate a door, it will stay open at all times.

The door has a hight of 78 inches, and is 36 inches wide

The sides of the shed are approximately 90 inches high and the apex of the roof 106 inches and a bit

I have no fully clad pictures as I did this as a friendly favor, and already had a bit of a tight schedule for myself ( I know I'm a terrible business man, had classes from Wayne ^^ right Wayne)

And an approximate amount of material phew lets see 4, 5 foot beams 5, 4 foot beams 6, 3+ footers, 6, 2,5 footers and they are all 3 by 3's

and then there are 6 5 foot beams from 2 by 3 or 2 by 4's

So about 80 to 90 foot of 3 by 3 beams and 30 foot of 2 by 4's

And you do the math on the cladding ^^

Ps Solidworks is a really easy to learn program with allot of tutorial videos available videos, though not really necessary for basic designs.

And Mister Squiders,

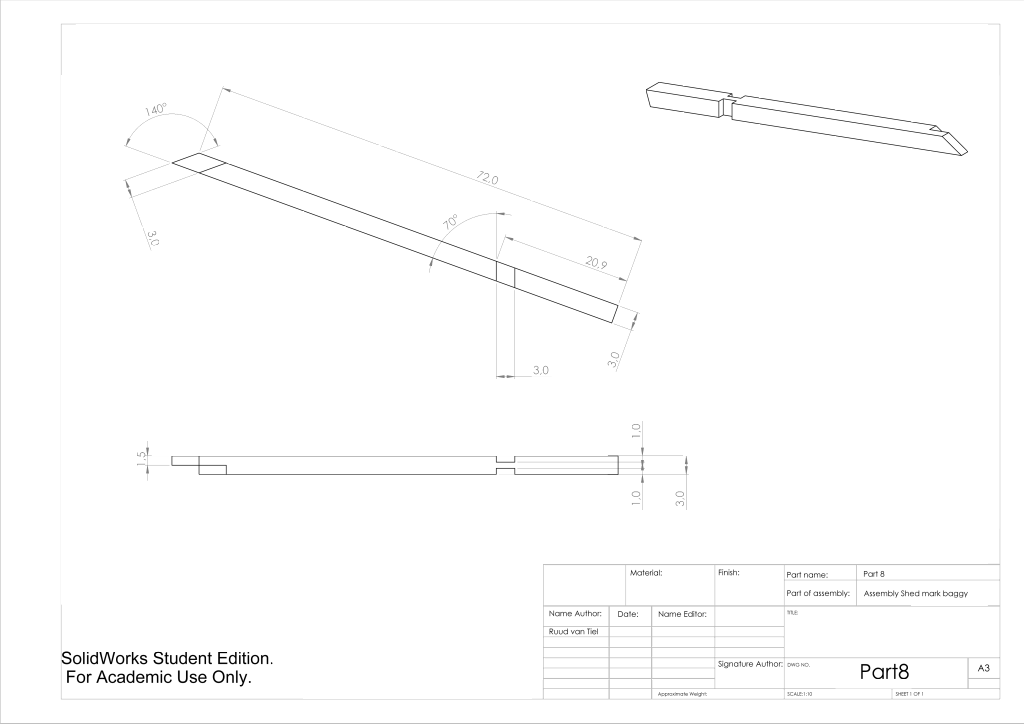

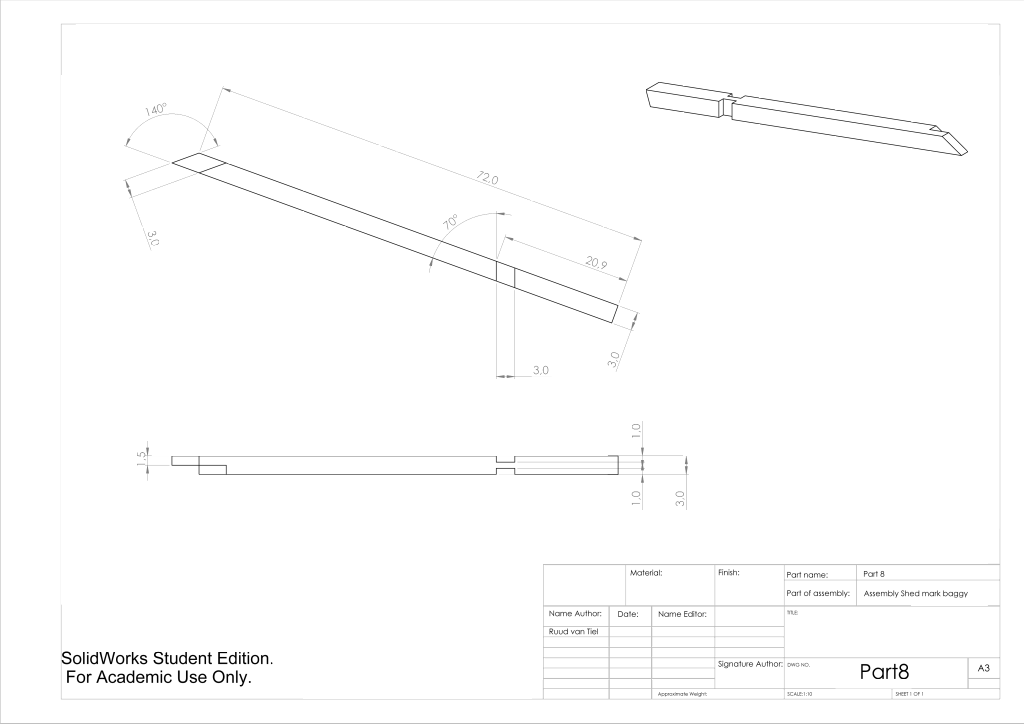

I made something of a hidden brace in the top which will give it more then enough strength

but I will post some pictures of the drawings which will display that more clearly

in the next post that will be

And Colin,

Perhaps you're right but hey what worth doing is worth overdoing right.

And to all the rest of you guys Thanks for the responses ^^

really appreciated

Yours sincerely Ruud

Wow what a massive response let me recollect myself ^^

Dear demographic,

I see exactly what you mean now, and yes I had thought about it but figured it to being a wee 4 by 4 feet shed it wouldnt need additional cross bracing,

but then again I'm only 20 springs young with zero knowledgeable people around me if it comes to anything wood, so have to figure that out on my own, I figured it to be strong enough and didn't think it would shift that much seeing the shed would be a semi open shed, as the left side of the shed was going to be clad so that there would be an inch gap between each board, this was an Idea of Baggy to have more air displacement in the shed to dry firewood and such. the humidity, and because of this open system the humidity would be the same outside as inside, which is usually the factor that makes most structures shift their shapes I figured it to be no problem, but then again experience is one of the best teachers so thanks for sharing that knowledge with me. might you ever want to talk some experience into me, my skype name is wcblokhoudertje.

Dear Lee,

I would be happy to help you with the design, and feel honored that you ask

yet I might have to put it on hold for a few weeks, as the coming 6 weeks are rushhour with my school

but after that I'd gladly do the deeds.

Dear sir Fish

The program

I'm using is indeed Solidworks 2012, which I'm used to, being a Industrial product Design student, and though not free software it is easily accessible through the torrent site of pirates ^^, a great ISO on there, which was a dream to install, Thank you SolidSquad ( the team that made free access possible)

Dear Roy,

Yeah cladding in sheet speeds up the process, but what also is the thing with multiplex is it doesnt shrink as it´s grain is turned 90 degrees each sheet, and held to gether with glue, this makes it almost un-hygroscopic meaning it is not affected by humidity. and in this case one side could be clad in that manner but the other because of the planned gaps is not.

And then here we go Mousey, prepare for thee answers ^^

Yes it does have a little porch, which could accommodate your more often used tools for easy access or perhaps a nice chair ^^

No windows but that is mainly because of the one inch gaps on the left wall of the shed and the rather large Door opening, which will not accommodate a door, it will stay open at all times.

The door has a hight of 78 inches, and is 36 inches wide

The sides of the shed are approximately 90 inches high and the apex of the roof 106 inches and a bit

I have no fully clad pictures as I did this as a friendly favor, and already had a bit of a tight schedule for myself ( I know I'm a terrible business man, had classes from Wayne ^^ right Wayne)

And an approximate amount of material phew lets see 4, 5 foot beams 5, 4 foot beams 6, 3+ footers, 6, 2,5 footers and they are all 3 by 3's

and then there are 6 5 foot beams from 2 by 3 or 2 by 4's

So about 80 to 90 foot of 3 by 3 beams and 30 foot of 2 by 4's

And you do the math on the cladding ^^

Ps Solidworks is a really easy to learn program with allot of tutorial videos available videos, though not really necessary for basic designs.

And Mister Squiders,

I made something of a hidden brace in the top which will give it more then enough strength

but I will post some pictures of the drawings which will display that more clearly

in the next post that will be

And Colin,

Perhaps you're right but hey what worth doing is worth overdoing right.

And to all the rest of you guys Thanks for the responses ^^

really appreciated

Yours sincerely Ruud

Last edited:

Don't worry, I'm not trying to pull this to bits here and many sheds are built without that cross bracing (the ones you buy for 200 quid from B&Q certainly don't have it).

The problem is that so many of them do end up slumping over away from the prevailing wind and as its so easy and cheap to sort out I personally feel that its worth the little extra effort.

Its not a big redesign, just a small tweak to the existing.

You're doing fine, keep it up.

The problem is that so many of them do end up slumping over away from the prevailing wind and as its so easy and cheap to sort out I personally feel that its worth the little extra effort.

Its not a big redesign, just a small tweak to the existing.

You're doing fine, keep it up.

Thanks Demo,

I think the second I will go over 4 feet I will start adding cross braces, or when I want it to last for more then 20 years

and indeed the redesign would be real easy, So Mark Baigent, or baggy. it is your call what you say?

Yours sincerely Ruud

I think the second I will go over 4 feet I will start adding cross braces, or when I want it to last for more then 20 years

and indeed the redesign would be real easy, So Mark Baigent, or baggy. it is your call what you say?

Yours sincerely Ruud

Dear mister Squiders

Here is the mystery drawing of the joint made in the Roof beams

Yours sincerely Ruud

Here is the mystery drawing of the joint made in the Roof beams

Yours sincerely Ruud

Don't worry, I'm not trying to pull this to bits here and many sheds are built without that cross bracing (the ones you buy for 200 quid from B&Q certainly don't have it).

The problem is that so many of them do end up slumping over away from the prevailing wind and as its so easy and cheap to sort out I personally feel that its worth the little extra effort.

Its not a big redesign, just a small tweak to the existing.

You're doing fine, keep it up.

And as has been said, if your cladding with sheet material, totally unneccessary.

Similar threads

- Replies

- 4

- Views

- 568