Check with a scrap yard or electrical contractor for copper. Ask about some large electrical panel BUSS BARS, or for some TERMINALS from transformers. I picked up two bars that measured 1 inch by 1 1/2 inches and 12 inches long! I also got a 9 inch long round bar 1 1/4 inches in diameter! That's a lot of copper! And many years ago, I traded for a small sheet of thick copper from a knife makers supply place. It was 1/4 inch thick, 1 3/4 inches wide, and 9 inches long. They were selling it for use in making the handle guards and butt caps.

Of course, this was all years ago before the scrap price of copper climbed through the roof! So copper won't be cheap these days. But a scrap yard might let you scrounge through their copper pile to see if something there will work for your forging. Yes, they will charge you lots for it, but at least you will be able to see and hold what you want before you buy it.

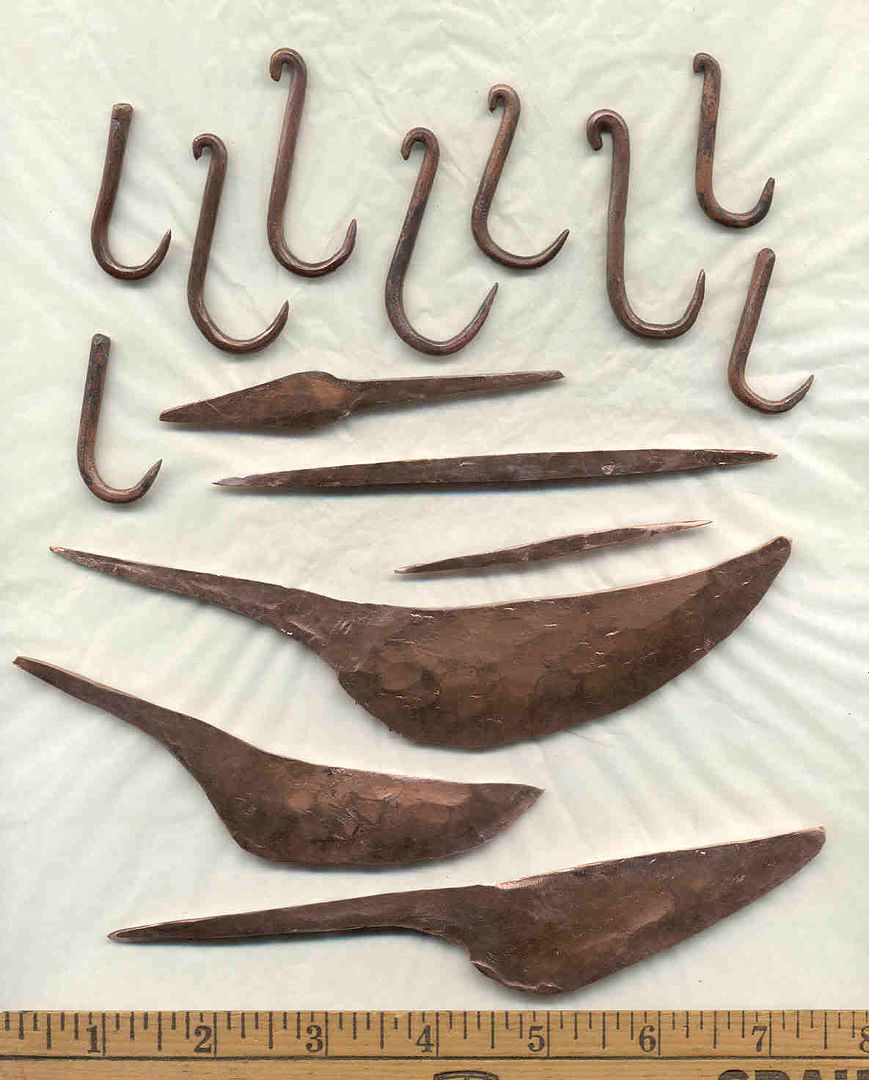

I posted this stuff below about some Copper Culture items I forged up last March. It was over on the Firecraft forum under the topic Wood Fired Smelter. It doesn't look like cut-n-paste grabbed the pic from the message, but I also put the pic that in my Photo Gallery, so check it out up there.

I'll be happy to help answer any questions if I can.

Mikey - yee ol' grumpy blacksmith out in the Hinterlands

---------------------------------------------------------------------------------------------------------------------------

Last summer I took a break from traditional blacksmithing, and I spent a couple days forging copper. I used all my normal blacksmithing tools and forge, but I started with copper. The hardest part is getting a big enough chunk of copper to start with. I scrounged up a copper wire, Lightning Rod aroung 9/16 inches round, and a big electrical Buss Bar 1 1/2 inch by 2 inches. I heated the copper up in my blacksmith forge. When it was glowing red, I then cut it into smaller chunks, and then forged those into the shapes I wanted.

I was making some replicas of some early Indian Copper Culture pieces for a park/museum up by the Great Lakes. The picture shows a group of fish hooks, a small tanged spear head, two awls, and several knife blades. I can't find the picture of the two big socketed spear heads.

I did the major forging/shaping with the copper hot - glowing red. I then finished each item by cold hammering them. The cold hammering hardens the copper, but too much makes it brittle and causes it to split/crack. Plus copper and brass heat-treat the opposite of steel. To heat-treat it hard, you let it air-cool. To soften it, you quench it in water.

Interesting little project. The pieces turned out pretty darn close to original artifacts. But it's is easy to tell the difference, since I started with modern refined copper. Now, I did pick up some raw copper nuggets to take it to the next level - work with the copper in it's original dug/found condition, and see how that works. These next pieces I better deeply mark - they would be too easy for someone to pass them off as originals. But forging copper is much harder than forging iron/steel. Copper absorbs the hammer blow, where iron/steel has some "rebound". So you have to work harder to bring the hammer back up after each blow. This will wear out your arm much much faster than you think it should.

So, I would advise you to find a bigger chunk of copper to start with to forge up your arrowheads. Big electrical junction boxes have copper Buss Bars in them. A scrap yard should have some scrap ones laying around. And they might have a copper grounding rod, also called a lightening rod - but make sure that it is solid copper and not just copper coated. You can buy new from an electric supply company, but you would end up paying a high price.

A wood fire will get copper hot enough to work - glowing red. Have a big enough wood fire with a good bed of coals. Adding a little extra air helps a lot. I have used a length of 1/4 inch pipe as a Blow-Tube to help the fire.

I hope this helps. Good luck on your adventure into working copper. But a word of warning. Blacksmithing is Addictive! And working copper is a close cousin!

yhs

Mike Ameling

) is after an Athame, and I was thinking of having a go at making one. Any suggestions? Somewhere to get round or square copper bar stock at a reasonable price? I know next to nothing about where to buy the stuff, other than pipes for plumbing. Earth rods used to be solid copper but all the ones I've found have been copper plated steel

) is after an Athame, and I was thinking of having a go at making one. Any suggestions? Somewhere to get round or square copper bar stock at a reasonable price? I know next to nothing about where to buy the stuff, other than pipes for plumbing. Earth rods used to be solid copper but all the ones I've found have been copper plated steel