So fancied having a go at a knife but not having a surplus of readies decided to see what I could do for as cheaply as possible, and as an exercise in re-purposing.

I had an old cheapo stainless chefs cleaver that's never been out of the back of the kitchen drawer for about 5 years, so it became the metal donor and after marking a fulltang design onto it I set about it with an angle grinder (well after discovering that my sense of humour doesn't stretch to persevering with a hacksaw that is ! )

)

Which gets us to this point: (there is a rough bevel hidden under the tape too)

In the meanwhile I tracked down some burr elm for scales, and nickel silver tubing etc to make lanyard tube and mosaic pins.

Roughed out all the bits and after colouring Araldite with laser printer toner, glued and and clamped it until set. At this point even being kind it looked UGLY ! and lacking promise.

But after a a few minutes on the disc sander at work, things were looking up.

Now this is the point where you would either use a good rasp or, preferably, a belt sander. I have neither and have no access to any, but I do have a vice, a piece of sanding belt and Tesco Value new potatoes.................yes I did say Tesco Value etc etc

So after marking the desired handle shape with the combination of working through the grades with the erm 'spud drum sander' and hand sanding (lots and lots and LOTS of hand sanding) it was beginning to look almost like a knife (and I was beginning to feel less hateful towards it). There was a fair bit of trial and error with the handle thickness and a fair bit more wood was removed after the pics below.

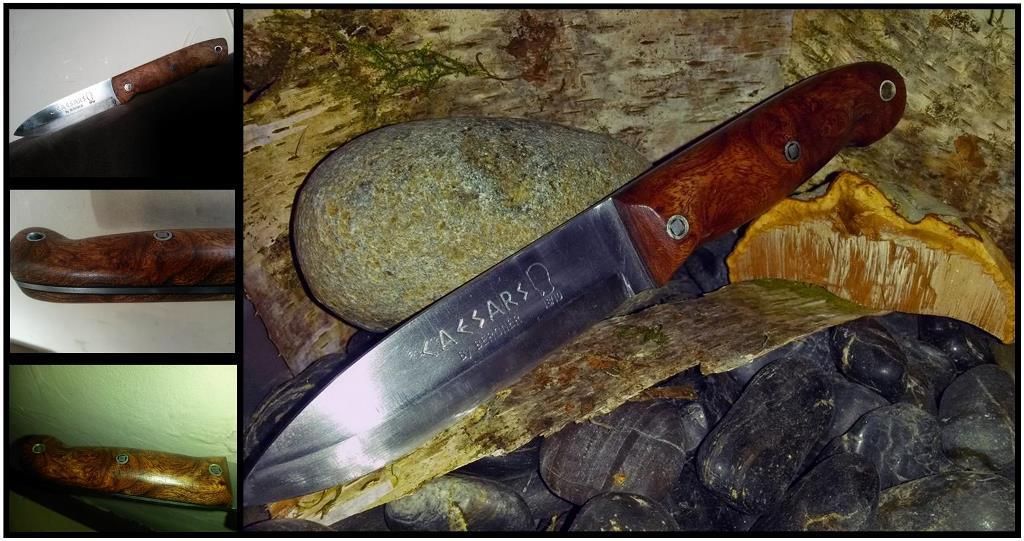

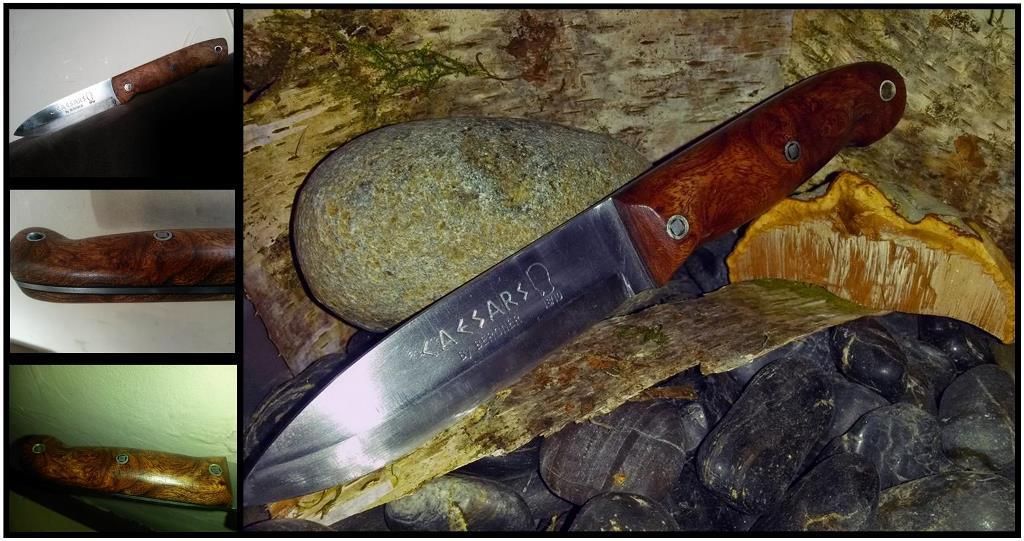

So after LOTS more sanding, then hand buffing with compound and a torn up bedsheet, I added half a dozen coats of teak oil and ended up with this:

Rough around the edges, and the bevel and plunge line is pooh but learnt loads in the process, and it is shaving sharp (surprisingly)......This knife making lark is addictive so it won't be my last.

At some stage I'll post the leather lanyard and hand turned lanyard bead (from same blank as the handle) and the dangler/not a dangler sheath I made too.

I had an old cheapo stainless chefs cleaver that's never been out of the back of the kitchen drawer for about 5 years, so it became the metal donor and after marking a fulltang design onto it I set about it with an angle grinder (well after discovering that my sense of humour doesn't stretch to persevering with a hacksaw that is !

Which gets us to this point: (there is a rough bevel hidden under the tape too)

In the meanwhile I tracked down some burr elm for scales, and nickel silver tubing etc to make lanyard tube and mosaic pins.

Roughed out all the bits and after colouring Araldite with laser printer toner, glued and and clamped it until set. At this point even being kind it looked UGLY ! and lacking promise.

But after a a few minutes on the disc sander at work, things were looking up.

Now this is the point where you would either use a good rasp or, preferably, a belt sander. I have neither and have no access to any, but I do have a vice, a piece of sanding belt and Tesco Value new potatoes.................yes I did say Tesco Value etc etc

So after marking the desired handle shape with the combination of working through the grades with the erm 'spud drum sander' and hand sanding (lots and lots and LOTS of hand sanding) it was beginning to look almost like a knife (and I was beginning to feel less hateful towards it). There was a fair bit of trial and error with the handle thickness and a fair bit more wood was removed after the pics below.

So after LOTS more sanding, then hand buffing with compound and a torn up bedsheet, I added half a dozen coats of teak oil and ended up with this:

Rough around the edges, and the bevel and plunge line is pooh but learnt loads in the process, and it is shaving sharp (surprisingly)......This knife making lark is addictive so it won't be my last.

At some stage I'll post the leather lanyard and hand turned lanyard bead (from same blank as the handle) and the dangler/not a dangler sheath I made too.