Hi weaver

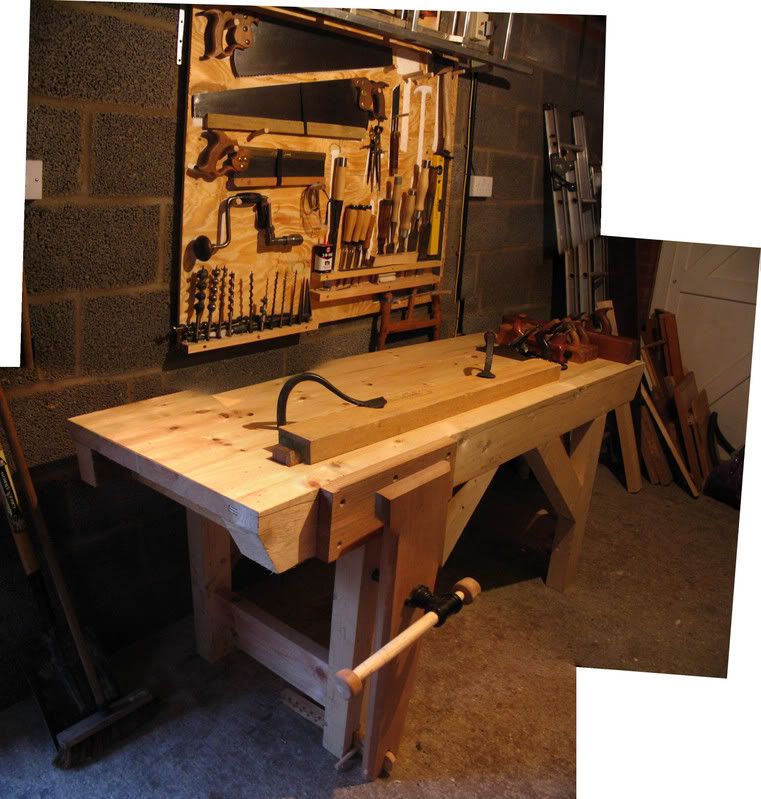

Thanks for your kind comment's about the bench. I've had to wait 15 or 16 years to be in a place where I could finally set up my own bench. It took me 2 "days" (IE about 8 hours) to build, plus an afternoon to flat the top with 2xstabila level's, smoothing, jack and jointer plane's. The frame is 6x4 and 4x3, the end stretchrs are 8x2, the top is made of 8x2's biscuit jointed with a 6x4 front and back apron to give additional solid support for chopping mortice's. I drew out the design full size on plywood and took all the positions for joints from that (French scribe lay out method-fast simple and fool proof, I dont like to mess with tapes its too easy to make expensive error's

If the drawing is right the job will come out right) It was draw-pegged together with 3/4 inch diam cleft oak pegs, no glue was used except to lanimate the 6x2's on the top. I added the iron hold fast's (made by a ocal blacksmith) and drilled 3/4 inch holes to acomodate them. There is a 2 inch square oak planing stop at the vice end it can be dropped down below bench suface when not being used. The bench is as solid as a rock, the diagonal braces (unusual for a bench) are extremely efficient at resisting the racking forces you get when planing, even when scrub planing boards that have been chain sawed. The gap underneath makes a convenient spot to store saw horses etc

Post vice's are greatly under rated (because they appear so simple I reckon, the "tool industry" wants us to pay for complex tail vice's and so on)

The great thing about it is it has phenomenal gripping power compaed to a regular joiner's vice. You can fit a board up to about 12 or 13 inches wide without snagging on the vice screw. Also the jaw's "give" slightly to grip slightly uneven or taper'd piece's, useful when shaping chair parts. The downside is having to bend down and adjust the peg on the bottom adjuster to acomodate different widths of stock. If I made another I'd make the front jaw thicker (say 1 1/2 or 1 3/4 inches instead of an inch for this one, it flexes a little sometimes, but its still solid. I saw a device in the workbench book (scott Landis) where a bloke who carved duck decoy's used a post vice but with a simple but effective cam lock to clamp the vice shut rather than a slower bench screw. Theres some great ideas in that book. I love the sabotier's benches in the links, low tech, no mechanical parts, easily repaired, or modified. A good carving or hewing bench doesnt necessarily have to be big, just solid and heavy. The old metods and devices seem crude initially, but theres a lot of sense in there designs, developed over many hundreds or even thousand's of years of pracical hands on experience

PS, I didnt make the small frame saw (its a marples one) but I have made other bigger ones from modified old disston saw blades.

Cheers Jonathan

The great thing about it is it has phenomenal gripping power compaed to a regular joiner's vice. You can fit a board up to about 12 or 13 inches wide without snagging on the vice screw. Also the jaw's "give" slightly to grip slightly uneven or taper'd piece's, useful when shaping chair parts. The downside is having to bend down and adjust the peg on the bottom adjuster to acomodate different widths of stock. If I made another I'd make the front jaw thicker (say 1 1/2 or 1 3/4 inches instead of an inch for this one, it flexes a little sometimes, but its still solid. I saw a device in the workbench book (scott Landis) where a bloke who carved duck decoy's used a post vice but with a simple but effective cam lock to clamp the vice shut rather than a slower bench screw. Theres some great ideas in that book. I love the sabotier's benches in the links, low tech, no mechanical parts, easily repaired, or modified. A good carving or hewing bench doesnt necessarily have to be big, just solid and heavy. The old metods and devices seem crude initially, but theres a lot of sense in there designs, developed over many hundreds or even thousand's of years of pracical hands on experience

The great thing about it is it has phenomenal gripping power compaed to a regular joiner's vice. You can fit a board up to about 12 or 13 inches wide without snagging on the vice screw. Also the jaw's "give" slightly to grip slightly uneven or taper'd piece's, useful when shaping chair parts. The downside is having to bend down and adjust the peg on the bottom adjuster to acomodate different widths of stock. If I made another I'd make the front jaw thicker (say 1 1/2 or 1 3/4 inches instead of an inch for this one, it flexes a little sometimes, but its still solid. I saw a device in the workbench book (scott Landis) where a bloke who carved duck decoy's used a post vice but with a simple but effective cam lock to clamp the vice shut rather than a slower bench screw. Theres some great ideas in that book. I love the sabotier's benches in the links, low tech, no mechanical parts, easily repaired, or modified. A good carving or hewing bench doesnt necessarily have to be big, just solid and heavy. The old metods and devices seem crude initially, but theres a lot of sense in there designs, developed over many hundreds or even thousand's of years of pracical hands on experience