A few days ago i had the hankering to build a new knife, so i ordered myself a Lauri 85 blade from Moonraker Accessories down in Wiltshire.

yesterday morning and into the early afternoon, saw me cutting birch bark (collected from my woods) and leather squares and then punching a hole in each one so it slid over the tang, i also spent a bit of time with some needle files getting a good fit on the brass bolster, once everything had been cut out and i had the required number of leather & birch layers, it was out with the epoxy resin and everything was layered up

Once it was all on and in position, i clamped it all up and left it overnight to ensure the epoxy had set, this morning, all was sound, so i spent a good amount of time cutting, shaping and sanding the handle to get from the squared section to a more refined and comfortable handle shape.

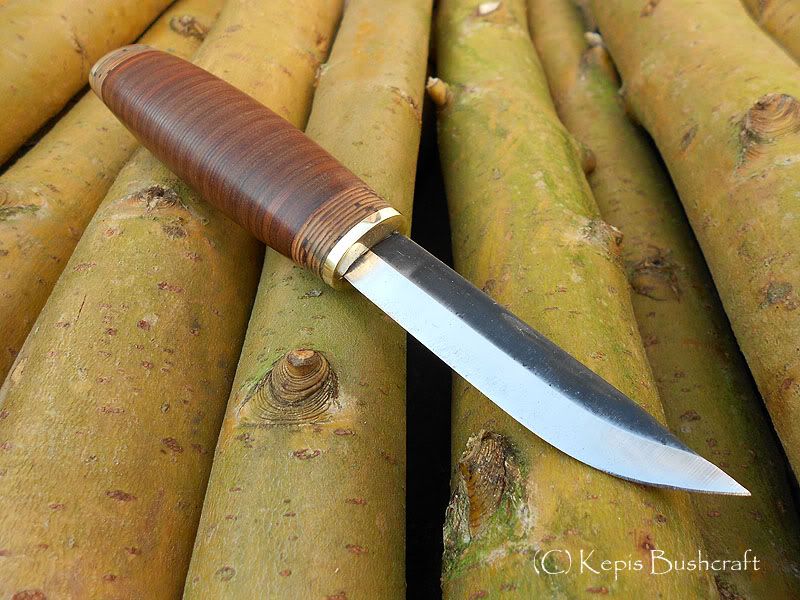

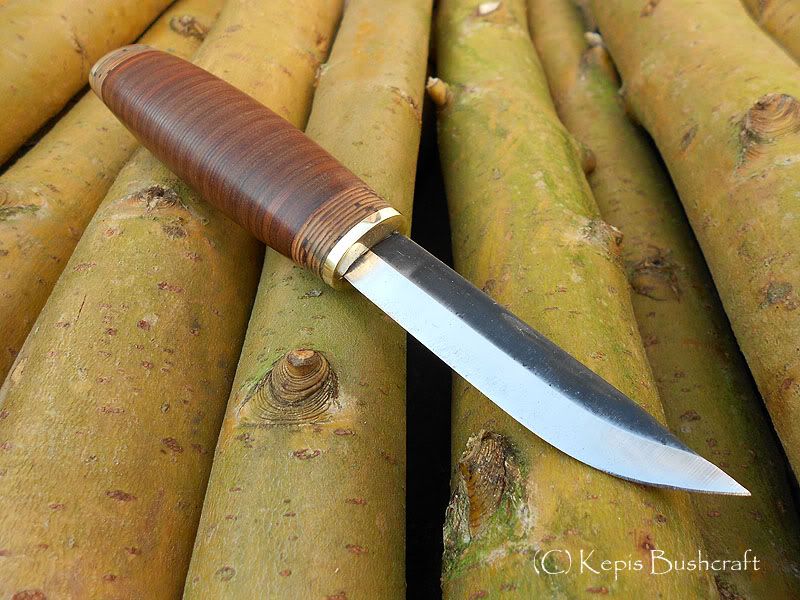

The result is this....

Brass washer pommel showing the peened end of the stick tang

close up of the stacked birch bark and leather handle, each layer of leather is approx 1mm thick

I'm pretty pleased with the way it's turned out, considering it's only the third knife ive ever built.

Ii would have liked to have built the entire handle from birch bark, but alas, i didnt have enough that was of a good enough standard, there are a few mistakes in the knife, but that's all part of the learning process and next time i will know and can avoid making the same mistakes again, all i need to do now is make myself a nice new sheath for it, I'm thinking of a Scandinavian style neck sheath, as it just seems appropriate.

yesterday morning and into the early afternoon, saw me cutting birch bark (collected from my woods) and leather squares and then punching a hole in each one so it slid over the tang, i also spent a bit of time with some needle files getting a good fit on the brass bolster, once everything had been cut out and i had the required number of leather & birch layers, it was out with the epoxy resin and everything was layered up

Once it was all on and in position, i clamped it all up and left it overnight to ensure the epoxy had set, this morning, all was sound, so i spent a good amount of time cutting, shaping and sanding the handle to get from the squared section to a more refined and comfortable handle shape.

The result is this....

Brass washer pommel showing the peened end of the stick tang

close up of the stacked birch bark and leather handle, each layer of leather is approx 1mm thick

I'm pretty pleased with the way it's turned out, considering it's only the third knife ive ever built.

Ii would have liked to have built the entire handle from birch bark, but alas, i didnt have enough that was of a good enough standard, there are a few mistakes in the knife, but that's all part of the learning process and next time i will know and can avoid making the same mistakes again, all i need to do now is make myself a nice new sheath for it, I'm thinking of a Scandinavian style neck sheath, as it just seems appropriate.