I seem to have aquired a small collection (like you do). Anyway, thought I'd share, they are from multiple sources and of varying styles - from Roman through to English trade and everything in between - even a fantasy piece or two.

The first three are of fairly typical viking designs common at that time ...from Jason01.

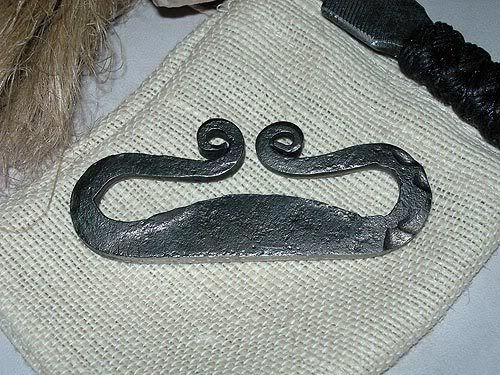

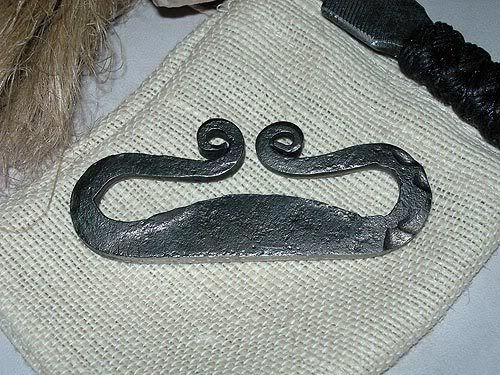

English Trade or Double Curl style that was standard trade steel from the early 1700's, and continued being traded up to the early 1800's. The French had a very similar fire steel, and one was found in the Montarina region of Cerro Veronese - as shown in the 1988 Exhibit Veronese Flintstones and the Flints of Europe. This style would have been carried by natives, colonists, or Continental, French, or English soldiers from the early 1700's through the French and Indian War and Rev war period, and longhunters ranging the Frontier. Based on originals pictured in The Museum of the Fur Trade Quarterly, Early American Antique Country Furnishing, The Kentucky Rifle Hunting Pouch by Madison Grant, and Fire Steels by Cacciandra and Cesati. Made by an American smith, Mike Ameling.

A viking style steel, inspired by designs from the mast heads of viking longboats. I'm not sure if such steels actually existed, but certainly viking smiths were able to produce them, were artisic enough and the design is contemporary. Possibly a slight flight of fancy rather than an acurate historical reproduction, but a beautifully made steel and the best sparker of all of them. Made by American smith, Darrel Aune

A large viking style steel, with the tails ornately twisted and tripple curled. Twisted steels of this type were not as common as the simply curved steels, but there are examples in the archaeological and literary records. One of my favourites. Another from Darrel Aune.

Single Finger Loop Colonial era fire steel or flint striker - also called a -D- or -n- style fire steel. This is based on an example dug up at Grand Portage MN (pictured in the book Where Two Worlds Meet), and was a common European trade item in the 1600's and 1700's. It would have been carried by a farmer, settler, hunter, soldier, or traded to one of the Tribes in the New World Colonies from the early 1600's up through the Revolution and beyond. Originals have been found throughout most areas of North America, but primarily the northern two thirds, especially along the Atlantic coast and along the Fur Trade routes through the Great Lakes. Examples are pictured in The Museum of the Fur Trade Quarterly, Where Two Worlds Meet, Voices From the Rapids, A Toast to the Fur Trade, Firearms Traps and Tools of the Mountain Men, and numerous other publications. The Victoria and Albert Museum in London has a catalog from Ross & Co. dated to 1797 that shows them offering three fire steel styles for sale - Ovals, Single Finger Loop, and Double Finger Loop. Another from Mike Ameling.

Burgundian Fire Steel - in the style of the formal necklace of the Order of the Golden Fleece. The Order of the Golden Fleece was created in 1430 by Philip the Good, Duke of Burgundy. It existed throughout the whole area in and around Burgundy, France, Austria, Spain, Italy, and even England, and continued on up through the 1700's. It also shows up in family crests and coats-of-arms for many families in Europe. This one is based on a picture in the book FIRE STEELS by Cacciandra and Cesati - Plate No. 30 dated to the 15th Century. And also on the various paintings and drawings depicting the Golden Fleece necklace. Several early drawings of Indians by the early explorers in North America depict them with a fire steel very similar to this one. Another from Mike Ameling.

Medieval fire steel with a single loop on top, and a little curl on the front for hanging it form a chain or leather thong. This style resembles the profile of a dogsled. Based on originals found at archeological sites throughout the whole range of the Roman Empire. Examples are pictured in the books FIRE STEELS by Cacciandra and Cesati, and FIRE STEEL by Sanctis and Fantoni. Because of the wide time range of Roman influence, it is hard to narrow the time frame for this style down to fewer than a couple hundred years. Originals of this style have been found with Roman artifacts from the 1st to 3rd century. Original fire steels like this varied in size from as small as 2 inches long by 1 inch high, on up to as big as 4 inches long by 2 inches or more high. And from as thin as 1/16 inch thick on up to a little over 1/4 inch thick. Another from Mike Ameling.

Fantasy Cobra-steel. A variation on the common C-shaped steel, with one end forged into a cobra's head. No historical precident. Great steel, another from American smith, Darrel Aune.

The first three are of fairly typical viking designs common at that time ...from Jason01.

English Trade or Double Curl style that was standard trade steel from the early 1700's, and continued being traded up to the early 1800's. The French had a very similar fire steel, and one was found in the Montarina region of Cerro Veronese - as shown in the 1988 Exhibit Veronese Flintstones and the Flints of Europe. This style would have been carried by natives, colonists, or Continental, French, or English soldiers from the early 1700's through the French and Indian War and Rev war period, and longhunters ranging the Frontier. Based on originals pictured in The Museum of the Fur Trade Quarterly, Early American Antique Country Furnishing, The Kentucky Rifle Hunting Pouch by Madison Grant, and Fire Steels by Cacciandra and Cesati. Made by an American smith, Mike Ameling.

A viking style steel, inspired by designs from the mast heads of viking longboats. I'm not sure if such steels actually existed, but certainly viking smiths were able to produce them, were artisic enough and the design is contemporary. Possibly a slight flight of fancy rather than an acurate historical reproduction, but a beautifully made steel and the best sparker of all of them. Made by American smith, Darrel Aune

A large viking style steel, with the tails ornately twisted and tripple curled. Twisted steels of this type were not as common as the simply curved steels, but there are examples in the archaeological and literary records. One of my favourites. Another from Darrel Aune.

Single Finger Loop Colonial era fire steel or flint striker - also called a -D- or -n- style fire steel. This is based on an example dug up at Grand Portage MN (pictured in the book Where Two Worlds Meet), and was a common European trade item in the 1600's and 1700's. It would have been carried by a farmer, settler, hunter, soldier, or traded to one of the Tribes in the New World Colonies from the early 1600's up through the Revolution and beyond. Originals have been found throughout most areas of North America, but primarily the northern two thirds, especially along the Atlantic coast and along the Fur Trade routes through the Great Lakes. Examples are pictured in The Museum of the Fur Trade Quarterly, Where Two Worlds Meet, Voices From the Rapids, A Toast to the Fur Trade, Firearms Traps and Tools of the Mountain Men, and numerous other publications. The Victoria and Albert Museum in London has a catalog from Ross & Co. dated to 1797 that shows them offering three fire steel styles for sale - Ovals, Single Finger Loop, and Double Finger Loop. Another from Mike Ameling.

Burgundian Fire Steel - in the style of the formal necklace of the Order of the Golden Fleece. The Order of the Golden Fleece was created in 1430 by Philip the Good, Duke of Burgundy. It existed throughout the whole area in and around Burgundy, France, Austria, Spain, Italy, and even England, and continued on up through the 1700's. It also shows up in family crests and coats-of-arms for many families in Europe. This one is based on a picture in the book FIRE STEELS by Cacciandra and Cesati - Plate No. 30 dated to the 15th Century. And also on the various paintings and drawings depicting the Golden Fleece necklace. Several early drawings of Indians by the early explorers in North America depict them with a fire steel very similar to this one. Another from Mike Ameling.

Medieval fire steel with a single loop on top, and a little curl on the front for hanging it form a chain or leather thong. This style resembles the profile of a dogsled. Based on originals found at archeological sites throughout the whole range of the Roman Empire. Examples are pictured in the books FIRE STEELS by Cacciandra and Cesati, and FIRE STEEL by Sanctis and Fantoni. Because of the wide time range of Roman influence, it is hard to narrow the time frame for this style down to fewer than a couple hundred years. Originals of this style have been found with Roman artifacts from the 1st to 3rd century. Original fire steels like this varied in size from as small as 2 inches long by 1 inch high, on up to as big as 4 inches long by 2 inches or more high. And from as thin as 1/16 inch thick on up to a little over 1/4 inch thick. Another from Mike Ameling.

Fantasy Cobra-steel. A variation on the common C-shaped steel, with one end forged into a cobra's head. No historical precident. Great steel, another from American smith, Darrel Aune.

That's a great selection. Have you got a preference for any in particular? I know you said that the Viking/fantasy one sparks the best but you might prefer another to use...

That's a great selection. Have you got a preference for any in particular? I know you said that the Viking/fantasy one sparks the best but you might prefer another to use...