Well I have made a couple more stacked birch bark handles as some wanted me to make him one. Iwas aked for a Polar whitller but I ordered a Lauri when a load of other Lauri blades and managed to add the Polar before the order was shipped so I made two knives. The finish on teh Lauri blade is what I got when I tried to polish the scale off but I liked so I left it as it is.

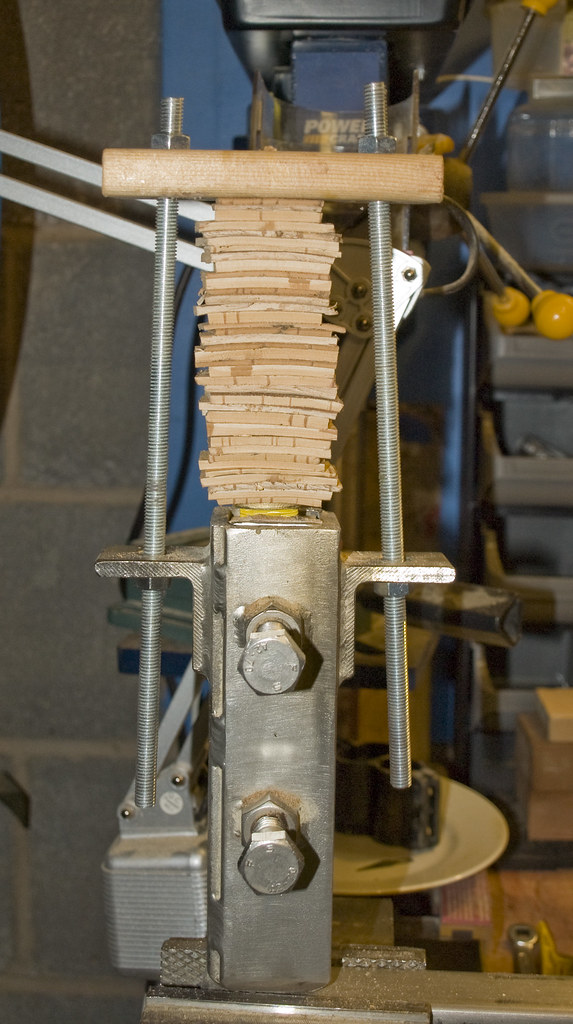

Before shaping them

Lauri & Polar stacked birch 1 by alf.branch, on Flickr

The one at bottom was made a while ago.

Lauri & Polar stacked birch 2 by alf.branch, on Flickr

Lauri & Polar stacked birch 3 by alf.branch, on Flickr

Lauri & Polar stacked birch 4 by alf.branch, on Flickr

Lauri & Polar stacked birch 5 by alf.branch, on Flickr

What do you think of them?

Before shaping them

Lauri & Polar stacked birch 1 by alf.branch, on Flickr

The one at bottom was made a while ago.

Lauri & Polar stacked birch 2 by alf.branch, on Flickr

Lauri & Polar stacked birch 3 by alf.branch, on Flickr

Lauri & Polar stacked birch 4 by alf.branch, on Flickr

Lauri & Polar stacked birch 5 by alf.branch, on Flickr

What do you think of them?