Some time back Bryan Breeden and I got into a conversation about "bushcrafter" style knives. About their roles and uses, In that conversation I told him that I thought I had a design that would be a good one that would add, in my personal opinion, some improvements over the traditional design making it a little more efficient. Considering one of the key elements of bushcraft is firecraft I wanted to add some features that made the knife a little more functional in that aspect...and so the testing began on a small scale. First I drew up and Bryan made the first small striker knives that worked really well. That led to the larger striker knife and the understanding that the features I wanted to incorporate into my bushcraft knife would indeed work well.

Then came the knife itself. I wanted a knife that would be unobtrusive enough that I could carry it in state wildlife parks without scaring people but robust enough to be able to stand alone in wilderness areas if needs be. One that was stout enough to perform many tasks yet light enough not to be a burden. One that was large enough to perform most camp and field tasks I would need to do such as game processing and vegetable cutting and still small enough to do detail work, and I really wanted it to function well in firecraft. With those thoughts in mind I call it the Sojourner.

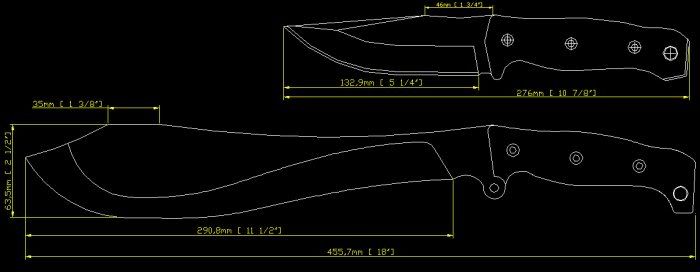

It is made of 1/8 inch O-1 steel with tan micarta scales. Has a modified drop point blade with a shallow sweep and needle sharp tip that has length of 5 inches, and an over-all of 10 inches.

The sheath has a couple of bugs that need to be worked out but it is close to what I wanted.

The handle is really comfortable in every grip I've tried it in.

and the scalloped and beveled spine perform exactly as I thought they would from previous testing.

I love how fatwood will not absorb water. It has been raining for days here and is supposed to rain for even more days still.

I think the size of the knife will be great for camping and hiking use, and as always the edge Bryan put on it is amazing.

As soon as the weather is a little better I'll get it out in the woods for a while to actually use it in more skills...hunting season will soon be here!

Then came the knife itself. I wanted a knife that would be unobtrusive enough that I could carry it in state wildlife parks without scaring people but robust enough to be able to stand alone in wilderness areas if needs be. One that was stout enough to perform many tasks yet light enough not to be a burden. One that was large enough to perform most camp and field tasks I would need to do such as game processing and vegetable cutting and still small enough to do detail work, and I really wanted it to function well in firecraft. With those thoughts in mind I call it the Sojourner.

It is made of 1/8 inch O-1 steel with tan micarta scales. Has a modified drop point blade with a shallow sweep and needle sharp tip that has length of 5 inches, and an over-all of 10 inches.

The sheath has a couple of bugs that need to be worked out but it is close to what I wanted.

The handle is really comfortable in every grip I've tried it in.

and the scalloped and beveled spine perform exactly as I thought they would from previous testing.

I love how fatwood will not absorb water. It has been raining for days here and is supposed to rain for even more days still.

I think the size of the knife will be great for camping and hiking use, and as always the edge Bryan put on it is amazing.

As soon as the weather is a little better I'll get it out in the woods for a while to actually use it in more skills...hunting season will soon be here!

but its still on the drawing board)

but its still on the drawing board)