Apologies if this is in the wrong section, please move if more appropriate elsewhere.

so, I’ve inherited a 17” wooden jointing plane with no iron. So I bought one off eBay.

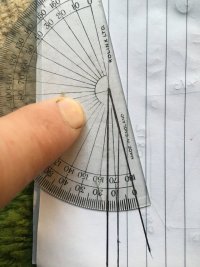

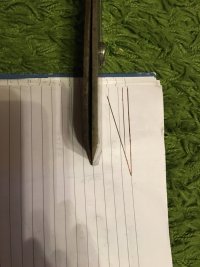

The iron was listed as new old stock and doesn’t appear to have been sharpened. The weird thing about it is that it is ground to about 15° not the usual 25-30°.

can anyone ahead any light as to why this might be? Have I bought a low angle iron by accident?

Thanks for any enlightenment

Tom

so, I’ve inherited a 17” wooden jointing plane with no iron. So I bought one off eBay.

The iron was listed as new old stock and doesn’t appear to have been sharpened. The weird thing about it is that it is ground to about 15° not the usual 25-30°.

can anyone ahead any light as to why this might be? Have I bought a low angle iron by accident?

Thanks for any enlightenment

Tom