inspired by a thread on a bowhunting forum,i decided to make a sheath knife suitable for rabbits and fish.in the original thread a circular saw blade was used apparently its a very good steel.so i rummaged in the shed and came up with an old circular saw blade from the old black and decker.

next thing was to sand the rust off.

next the area to be cut needed masking.

then i had to decide on a design,not wanting an exact copy of the inspiration i changes several angles,and finally ended up wit a nice drop point blade design.

next was to cut it out with the dremmel,using a fiber cutting disk on maximum speed.

heres the rough cut blank needing a go round with the sander on the dremmel.

next was to select materials for the handle or as known in the knife making world 'scales'.having a vast range of woods and other materials about i decided on a base of ebony laminated with some nice dexter bull bone that bodger gave me on my recent visit,the creamy ivory look of the bone should be enhanced with the real ebony.

the bone scales were cut out of the thicker side of the dexter bone and sanded flat here they are laid out next to the blade.

my new sander turned up so i got on with shaping the scales and sticking the bone to the ebony scales.

tomorrow when the glue has set i will start shaping them,also on the list of jobs to do is heating up the tang of the blade so that is loses temper and i can drill it ready for the brass pins.

first i had to heat the blade inorder to un-temper it so i could drill the 2 holes for the brass pins to secure the handle.

after that i successfully drilled the holes.

then the steel was re-tempered.after this I temporarilly affixed the scales so i could ensure a good fit by sanding.

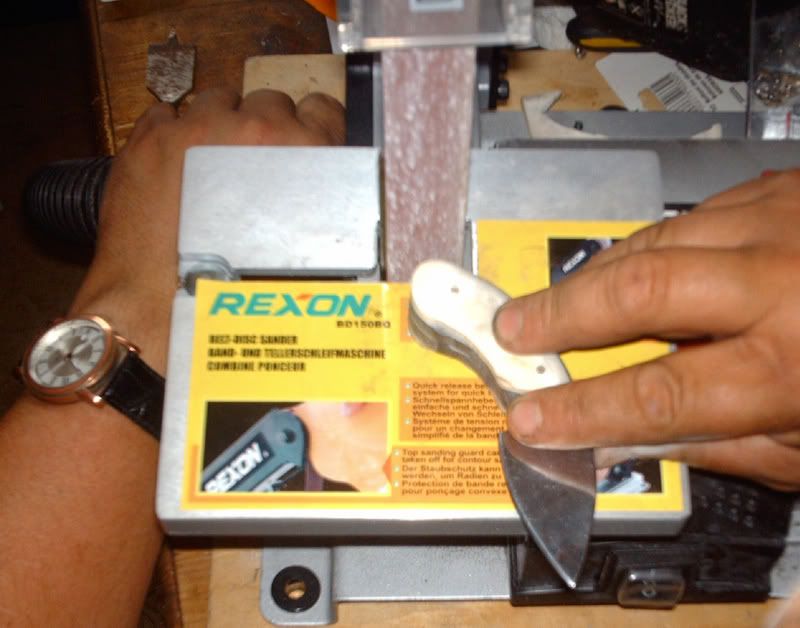

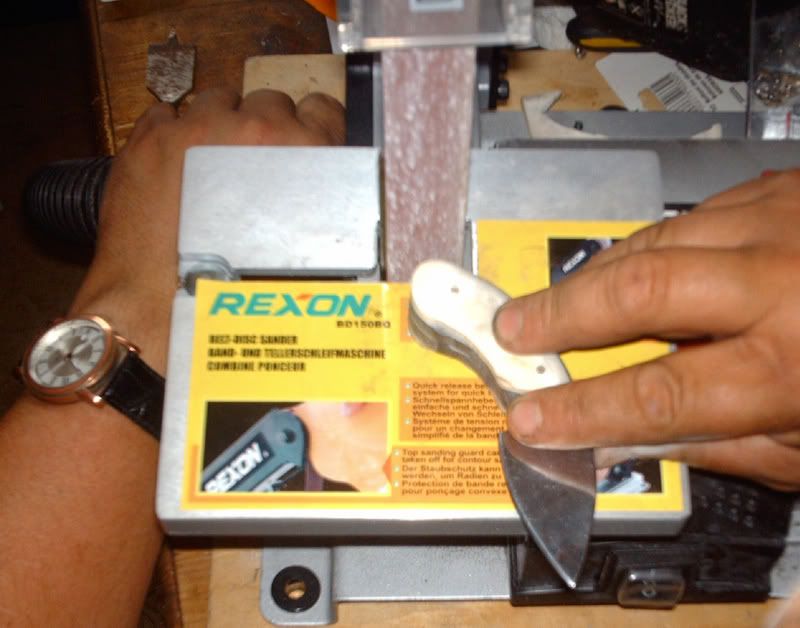

which i did with my new fangled sander.

and here they are in the rough so to speak.

the next task was to fit the scales permanantly,i used the contact adhesive then the brass pins were inserted and hammered in.then they were cut and sanded flush.so here it is near to completion,the shape it set.

and here it is now ille spend a couple of hours with very fine sand paper and then polish!

and here it is !!!!!!!!!!! blade and scales polished to a mirror finish,the photo doesnt do it justice realy!

ive hadd great fun making this and i will make another slightly larger for bush craft use.

next thing was to sand the rust off.

next the area to be cut needed masking.

then i had to decide on a design,not wanting an exact copy of the inspiration i changes several angles,and finally ended up wit a nice drop point blade design.

next was to cut it out with the dremmel,using a fiber cutting disk on maximum speed.

heres the rough cut blank needing a go round with the sander on the dremmel.

next was to select materials for the handle or as known in the knife making world 'scales'.having a vast range of woods and other materials about i decided on a base of ebony laminated with some nice dexter bull bone that bodger gave me on my recent visit,the creamy ivory look of the bone should be enhanced with the real ebony.

the bone scales were cut out of the thicker side of the dexter bone and sanded flat here they are laid out next to the blade.

my new sander turned up so i got on with shaping the scales and sticking the bone to the ebony scales.

tomorrow when the glue has set i will start shaping them,also on the list of jobs to do is heating up the tang of the blade so that is loses temper and i can drill it ready for the brass pins.

first i had to heat the blade inorder to un-temper it so i could drill the 2 holes for the brass pins to secure the handle.

after that i successfully drilled the holes.

then the steel was re-tempered.after this I temporarilly affixed the scales so i could ensure a good fit by sanding.

which i did with my new fangled sander.

and here they are in the rough so to speak.

the next task was to fit the scales permanantly,i used the contact adhesive then the brass pins were inserted and hammered in.then they were cut and sanded flush.so here it is near to completion,the shape it set.

and here it is now ille spend a couple of hours with very fine sand paper and then polish!

and here it is !!!!!!!!!!! blade and scales polished to a mirror finish,the photo doesnt do it justice realy!

ive hadd great fun making this and i will make another slightly larger for bush craft use.