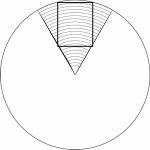

You maybe know all this but here's my thoughts. To be honest it depends on what tools you've got to hand. For tool handles I cut to approximate length before trying to split so, for hammer handles, I guess that would be about 40cm? That makes it a lot easier to split. I'm usually making axe handles so they vary from only 30cm to full felling axe length. Ideally you want the grain to be fairly horizontal as you look at it from a cut end:

View attachment 57859

I use a variety of tools from axe and wedges to a froe and, sometimes because a piece of wood is twisted, I'll saw it. So, depending on the diameter of the piece you are using, I would split it in half then split again (and maybe even again) - axe and wooden wedges will make a decent job usually. Getting the piece you end up with flat can be done with an axe, knife (battoning through), a draw knife or similar (that's where a shave horse comes in and why I've just made one

) or even a plane - an electric one is great.

The purists say not to use wood in the round for handles - I think because it's inclined to split more. However, when I've needed to fashion a handle quickly in the wood I've successfully made a temporary one that way that's lasted years

. Just give it plenty of oil.

OK, safety does come into it; you don't want a hammer head flying off - but I like to try things out and see what works myself so just have a go