I never met my grandfather, who died in 1955. Of the three things I inherited from him, one is an old axe.

A professional soldier who had served four years in Flanders, he joint the german police after the great war. Being sick of the political riots in Berlin in the twenties he asked for a transfer to the Gendarmerie.

Upon leaving he was giving this axe from his colleagues as a farewell present. I am sure they made some jokes on his expense at this occassion, since he was to be posted in eastern Prussia in the middle of the winter (my grandmother told me once that they had to travel in an unheated car at -30 degree Celsius). So he obviously needed an axe.

The handle was in quite a bad shape, when I decided to restore it

and the head was very loose fitting, having about 20mm of axial play. The head itself was in a good condition. No mushrooming of the poll, no deformation of the eye but lots of scratches and a nonexisting edge. Interstingly, the eye was not tapered, but straight. Which was to give me a bit trouble later when re-fitting the head.

The aim of my restoration was not to get the axe in perfect working order again, but to preserve as many parts of it as possible. Therefore I decided to reuse the original handle by simply shorten it a bit. This was possible since the shoulder was quite long and I had done something like this before with a badly hung Wetterlings.

The handle was hammered as far out of the head as possible and then sawn off. The rotten and splintered wood at the upper and lower edges were filed of and the surfaces sanded plan.

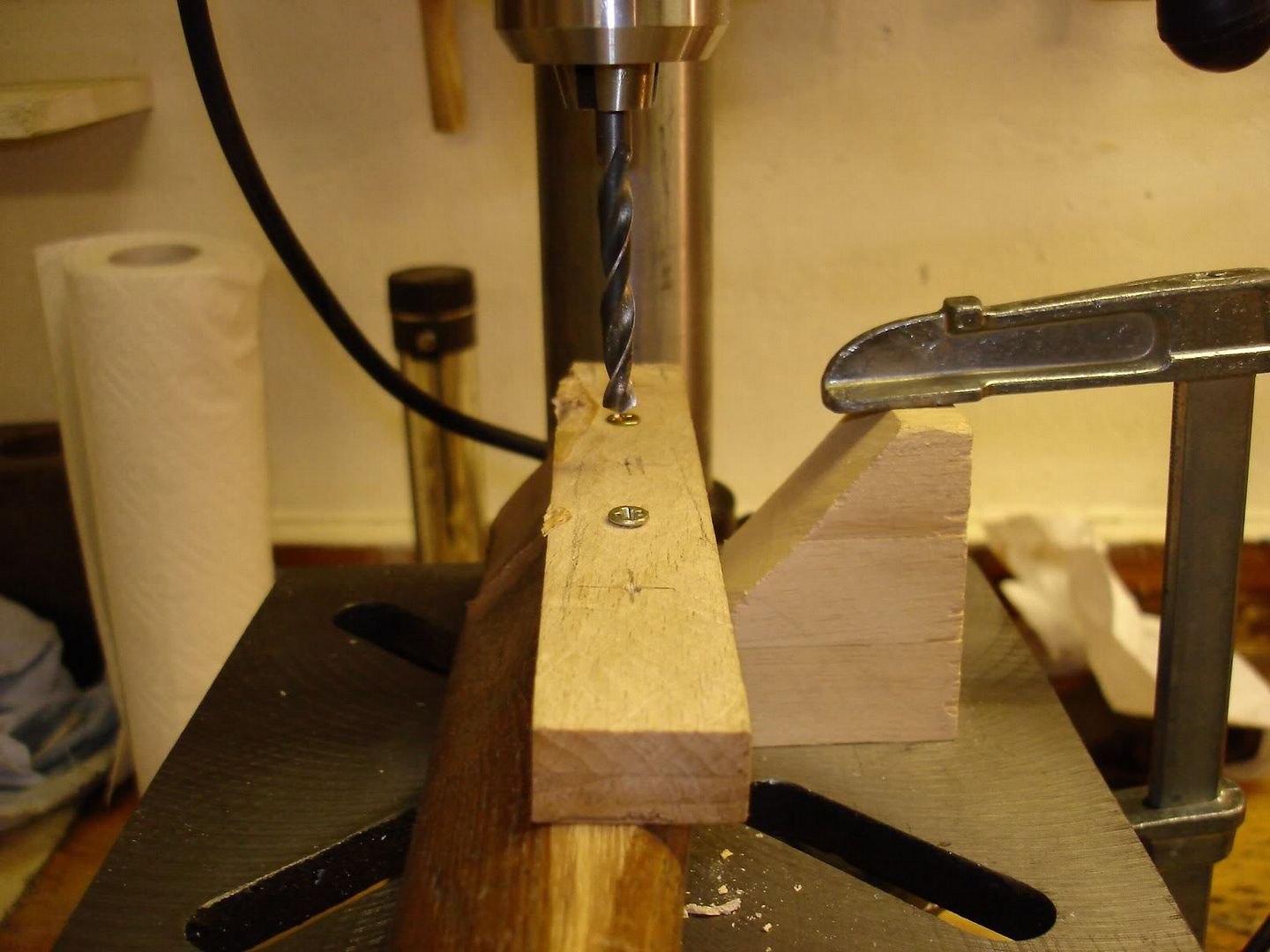

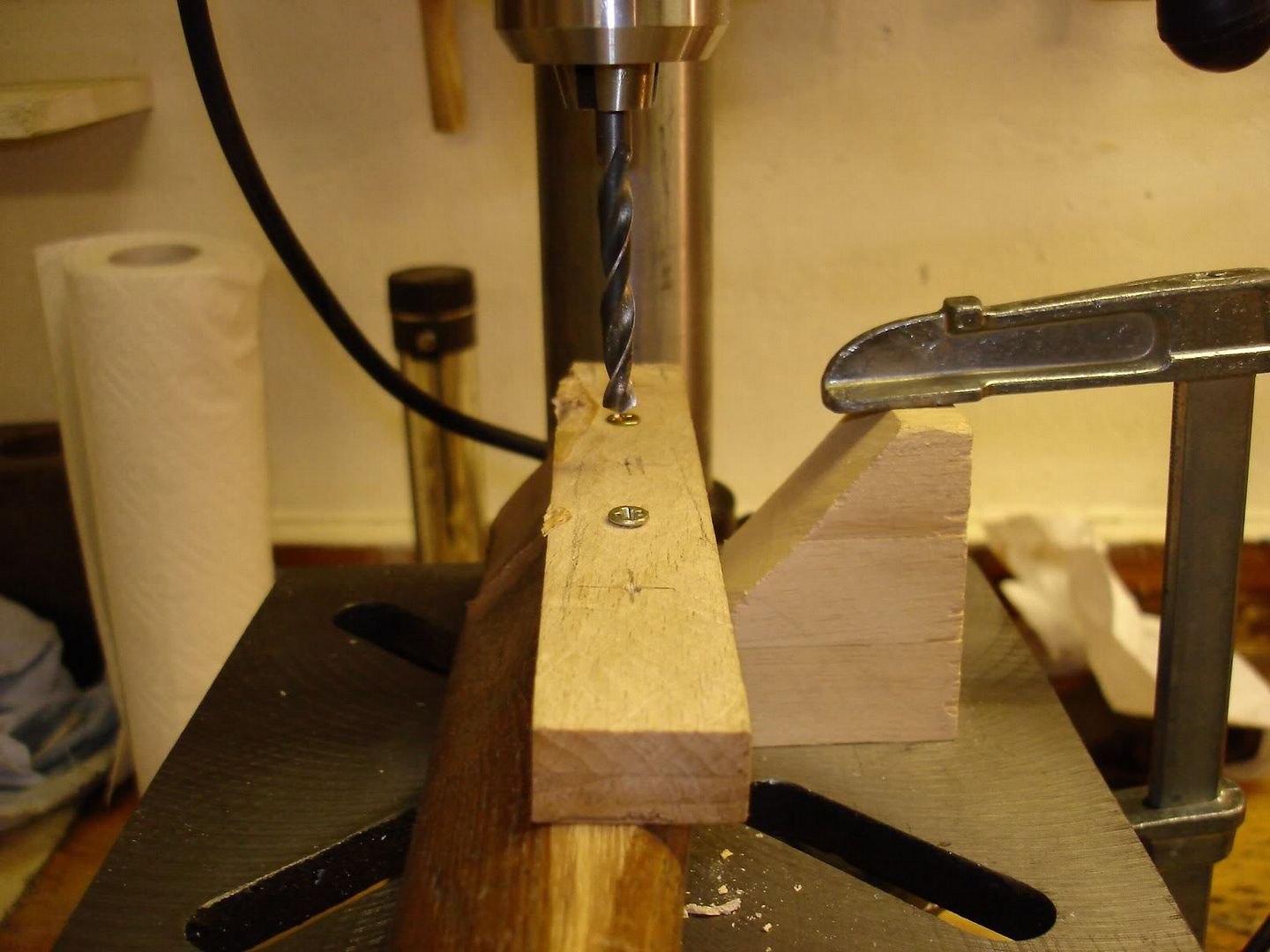

Pieces of seasoned hardwood were screwed on and then holes drilled to accomodate wooden pegs.

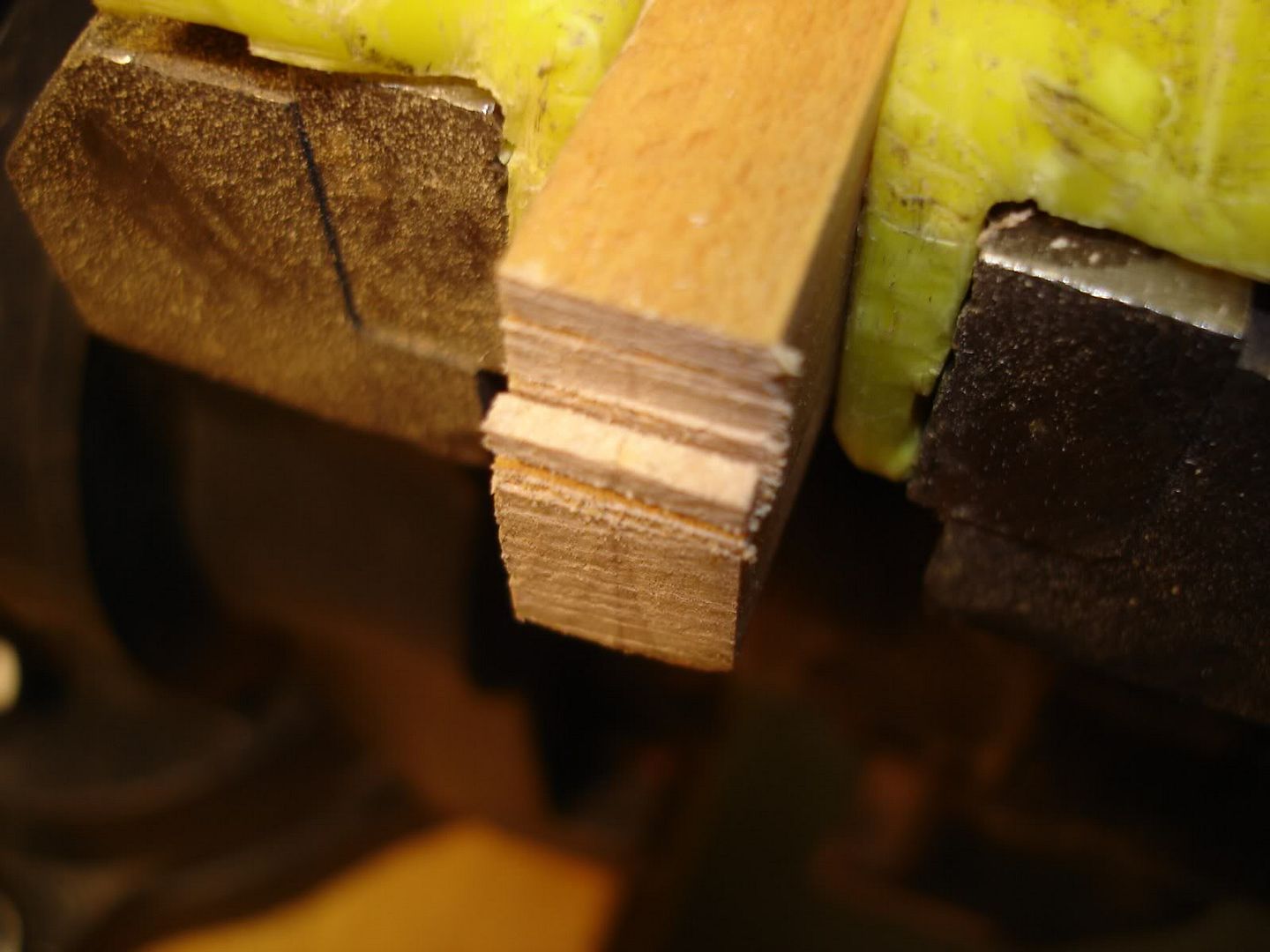

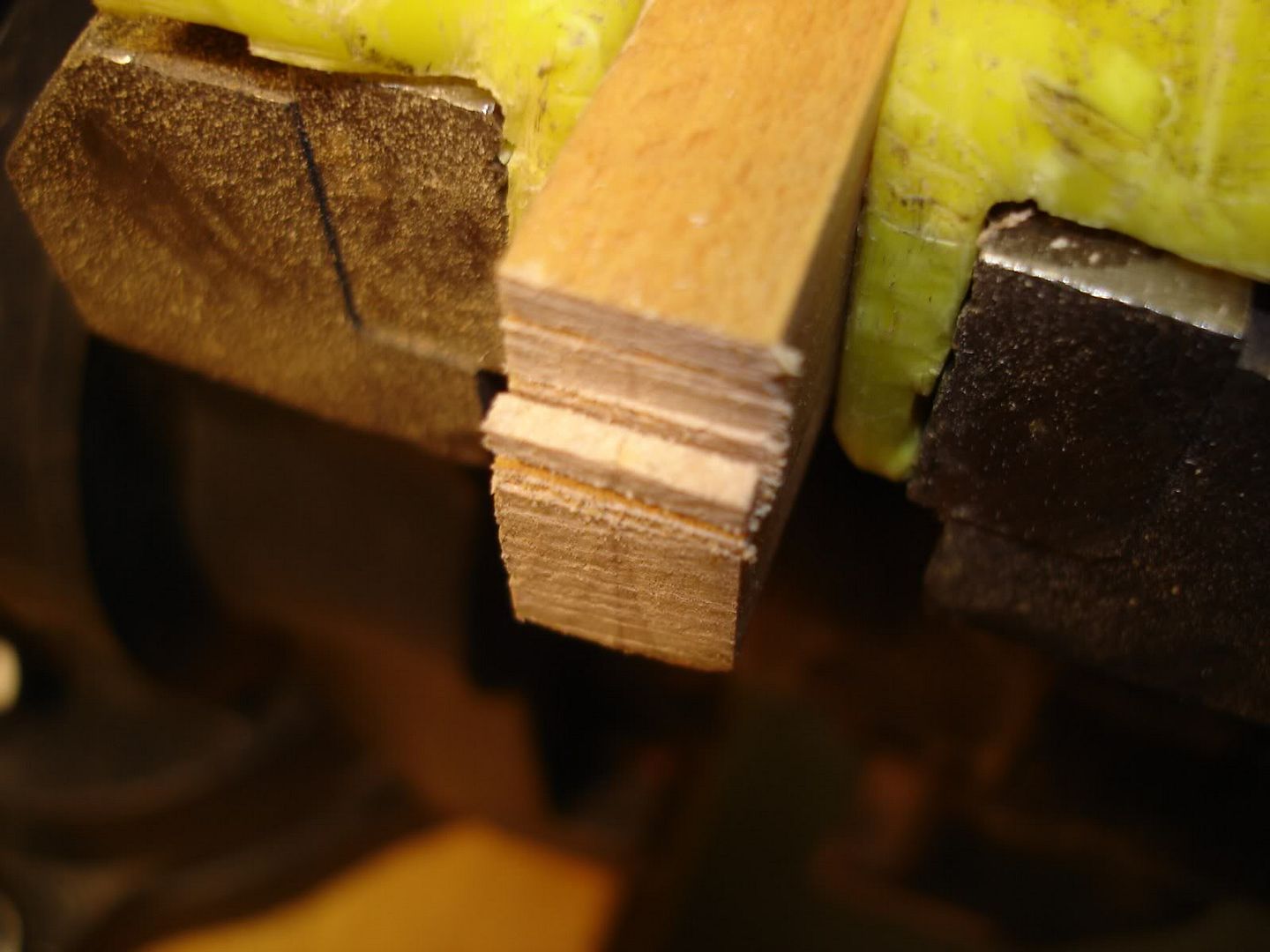

The wood was then attatched to each other using Ponal and three pegs on each edge. Due to the irregular shape of the handle it wasnt possible to use clamps everywhere. On the upper edge most of the pressure was applied with special screws as used for chipboard. After the shoulder was filed in shape the lower edge could be be attatched with the clamps.

The handle was then filed in the right shape.

The head was pitted from corrosion on the inside.The diamond-coated tip of a special drill on my Proxxon tool soon removed the worst bumps.

Then it was simply a matter of fitting the head correctly and adding the wedges.

The little holes from the screws, those who were still visible,

had to be closed with handmade pegs. For this purpose small pieces of wood (ca 3x3x15mm) were sawed off the leftowers of the used hardwood, roughly wittled in shape and lightly hammered in together with some glue.

Half an hour working on the edge with several waterstones ranging rom 80-600 grid made it look half decent again.

In this stage, it looked like an axe again.

Unfortunately, the straight eye had caused the handle to slip 2cm further on the handle than I wanted. From an original lenght of 59cm I am now down to 53cm.

Here the axe is in direct comparison with GBA`s SFA and LFA:

There is still a lot to do:

-dyeing the replacement wood to get a uniform apearance

-soaking the head in linseed oil/refined turpentine

-making a decent sheat

-creating a good edge.

This wont be an axe to carry in the wilderness for a couple of month or to do heavy felling. For this purpose I would had to have fitted an entirely new handle. I will exhibit it in my livingroom and, since this is still a tool, sometimes use it for small chores in the woods like making a fire for a brewup.

Right now, I am quite proud of my work.

A professional soldier who had served four years in Flanders, he joint the german police after the great war. Being sick of the political riots in Berlin in the twenties he asked for a transfer to the Gendarmerie.

Upon leaving he was giving this axe from his colleagues as a farewell present. I am sure they made some jokes on his expense at this occassion, since he was to be posted in eastern Prussia in the middle of the winter (my grandmother told me once that they had to travel in an unheated car at -30 degree Celsius). So he obviously needed an axe.

The handle was in quite a bad shape, when I decided to restore it

and the head was very loose fitting, having about 20mm of axial play. The head itself was in a good condition. No mushrooming of the poll, no deformation of the eye but lots of scratches and a nonexisting edge. Interstingly, the eye was not tapered, but straight. Which was to give me a bit trouble later when re-fitting the head.

The aim of my restoration was not to get the axe in perfect working order again, but to preserve as many parts of it as possible. Therefore I decided to reuse the original handle by simply shorten it a bit. This was possible since the shoulder was quite long and I had done something like this before with a badly hung Wetterlings.

The handle was hammered as far out of the head as possible and then sawn off. The rotten and splintered wood at the upper and lower edges were filed of and the surfaces sanded plan.

Pieces of seasoned hardwood were screwed on and then holes drilled to accomodate wooden pegs.

The wood was then attatched to each other using Ponal and three pegs on each edge. Due to the irregular shape of the handle it wasnt possible to use clamps everywhere. On the upper edge most of the pressure was applied with special screws as used for chipboard. After the shoulder was filed in shape the lower edge could be be attatched with the clamps.

The handle was then filed in the right shape.

The head was pitted from corrosion on the inside.The diamond-coated tip of a special drill on my Proxxon tool soon removed the worst bumps.

Then it was simply a matter of fitting the head correctly and adding the wedges.

The little holes from the screws, those who were still visible,

had to be closed with handmade pegs. For this purpose small pieces of wood (ca 3x3x15mm) were sawed off the leftowers of the used hardwood, roughly wittled in shape and lightly hammered in together with some glue.

Half an hour working on the edge with several waterstones ranging rom 80-600 grid made it look half decent again.

In this stage, it looked like an axe again.

Unfortunately, the straight eye had caused the handle to slip 2cm further on the handle than I wanted. From an original lenght of 59cm I am now down to 53cm.

Here the axe is in direct comparison with GBA`s SFA and LFA:

There is still a lot to do:

-dyeing the replacement wood to get a uniform apearance

-soaking the head in linseed oil/refined turpentine

-making a decent sheat

-creating a good edge.

This wont be an axe to carry in the wilderness for a couple of month or to do heavy felling. For this purpose I would had to have fitted an entirely new handle. I will exhibit it in my livingroom and, since this is still a tool, sometimes use it for small chores in the woods like making a fire for a brewup.

Right now, I am quite proud of my work.