Nine years ago Stuart showed me a tool that he had acquired on a trip to Sweden, which he thought was possibly the best jungle blade he had seen or used. It was a Finnish military issue billhook. These were out of production then, and those that are now in production are missing one of the key features, namely the integral guard.

So, why did Stuart think this tool so wonderful, well, paraphrasing, in use it had reach, the hook could be used for picking wood up from the ground, saving energy, and for catching and deflecting rattan tendrils and other spiky jungle flora. In addition, it was safer than a parang in that it had no point and either the guard or hook would tend to hit a careless user before the edge reached them, making accidents much more unlikely.

This is one of the few pictures anywhere on-line of what the tool looked like, only the one I saw had an olive coated blade and ferrule.

Sadly, this unique tool was lost during a capsizing while crossing a jungle reservoir.

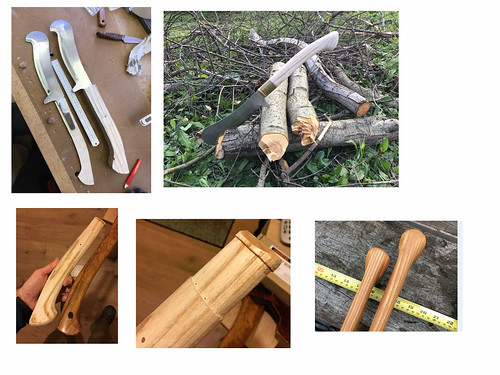

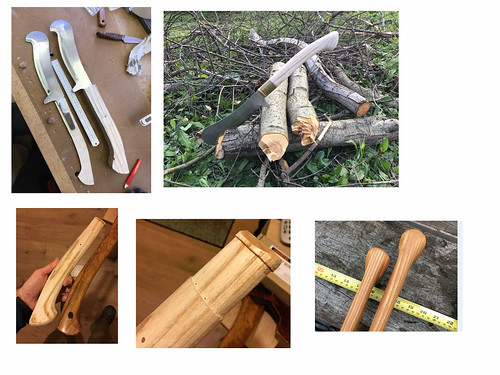

Rather foolishly, I offered to have a go at making a replacement. I got the blades cut out about seven years ago, then for various reasons, didn't get back to it. The main reasons were that Stuart had got himself a nice Ben Orford Parang, which he was doing well with (and not losing!) and there were a number of challenges to overcome with the design. How to grind it and how to mount it in a handle where the big ones. Followed by questions about materials and sheath design.

This year I finally pulled my finger out and got to it, having decided go with ash for the handle, Kydex for the sheath, a hidden tang, pin and wire wrap instead of the welded ferrule of the original, no powder coating, and a convex grind, that wouldn't be so fussy about me maintaining a clean even line around the curves.

Billhook comp by Last Scratch, on Flickr

Billhook comp by Last Scratch, on Flickr

After all that time, I mislaid my drawing of the handle, so modelled it after a GB SFA and some of the parang handles I have seen. I did the deep blind hole using a pen drill and home made handle broach. Went pretty quick and had a mostly rectangular hole that lined up well with the rough profiled blank.

Wire wrap was 0.5 locking wire, used to secure bolt heads. Two layers, applied under tension and covered with heat thinned slow cure epoxy. There is a single 1/8 brass pin through the end of the tang to insure against the blade exiting the handle in use.

Before finishing the handle I took the first tool out for a bit of a test. It cut so well I rather fancy one of these myself now. So far, no failure of that blade/handle joint.

Handles were soaked for days in Danish oil, kept wet. Handle life is something that bothers me, the jungle tends to be hard on wood!

Billhook Sheath by Last Scratch, on Flickr

Billhook Sheath by Last Scratch, on Flickr

For the sheath, I ordered an A3 size sheet of "orange" Kydex from a UK company on Ebay. Was slightly disappointed in the colour. While technically it IS orange, it is not the bright "hunter" orange that you get from all the US suppliers when they advertise materials as "orange". It is closer to fallen leaf colour than I would have liked!

Shaping a sheath for such an odd blade shape was interesting. I needed a lot of blocking out, basically in-filling all the hook, and the bevel, using cardboard and tape. If one had a number of these to do, it would be better to use a dummy blade, without hook or bevel, to shape the end of the sheath, then swap for the real one to shape the area near the handle. The keeper strap was made from Biothane, webbing coated in plastic. Not so easy to find. The place that had great prices on Ebay was based in Germany and wanted £12 to ship to the UK. If one was ordering from the US, they sell "inside the waist band" holster straps that come ready made with snaps, screws and plastic webbing. Chicago screws have an 8-32 thread, and I happened to have some 8-32 x 1" button heads that I could cut and grind down to fit inside the 15mm snaps.

I am pleased with how they all turned out. They are not pretty, and not the best finished of my work by any means, but as a gift of working tools, they will do.

Now, if someone else were to fancy making things like this, that would be great...I could point Stuart in their direction when he needs some spares!

So, why did Stuart think this tool so wonderful, well, paraphrasing, in use it had reach, the hook could be used for picking wood up from the ground, saving energy, and for catching and deflecting rattan tendrils and other spiky jungle flora. In addition, it was safer than a parang in that it had no point and either the guard or hook would tend to hit a careless user before the edge reached them, making accidents much more unlikely.

This is one of the few pictures anywhere on-line of what the tool looked like, only the one I saw had an olive coated blade and ferrule.

Sadly, this unique tool was lost during a capsizing while crossing a jungle reservoir.

Rather foolishly, I offered to have a go at making a replacement. I got the blades cut out about seven years ago, then for various reasons, didn't get back to it. The main reasons were that Stuart had got himself a nice Ben Orford Parang, which he was doing well with (and not losing!) and there were a number of challenges to overcome with the design. How to grind it and how to mount it in a handle where the big ones. Followed by questions about materials and sheath design.

This year I finally pulled my finger out and got to it, having decided go with ash for the handle, Kydex for the sheath, a hidden tang, pin and wire wrap instead of the welded ferrule of the original, no powder coating, and a convex grind, that wouldn't be so fussy about me maintaining a clean even line around the curves.

Billhook comp by Last Scratch, on Flickr

Billhook comp by Last Scratch, on FlickrAfter all that time, I mislaid my drawing of the handle, so modelled it after a GB SFA and some of the parang handles I have seen. I did the deep blind hole using a pen drill and home made handle broach. Went pretty quick and had a mostly rectangular hole that lined up well with the rough profiled blank.

Wire wrap was 0.5 locking wire, used to secure bolt heads. Two layers, applied under tension and covered with heat thinned slow cure epoxy. There is a single 1/8 brass pin through the end of the tang to insure against the blade exiting the handle in use.

Before finishing the handle I took the first tool out for a bit of a test. It cut so well I rather fancy one of these myself now. So far, no failure of that blade/handle joint.

Handles were soaked for days in Danish oil, kept wet. Handle life is something that bothers me, the jungle tends to be hard on wood!

Billhook Sheath by Last Scratch, on Flickr

Billhook Sheath by Last Scratch, on FlickrFor the sheath, I ordered an A3 size sheet of "orange" Kydex from a UK company on Ebay. Was slightly disappointed in the colour. While technically it IS orange, it is not the bright "hunter" orange that you get from all the US suppliers when they advertise materials as "orange". It is closer to fallen leaf colour than I would have liked!

Shaping a sheath for such an odd blade shape was interesting. I needed a lot of blocking out, basically in-filling all the hook, and the bevel, using cardboard and tape. If one had a number of these to do, it would be better to use a dummy blade, without hook or bevel, to shape the end of the sheath, then swap for the real one to shape the area near the handle. The keeper strap was made from Biothane, webbing coated in plastic. Not so easy to find. The place that had great prices on Ebay was based in Germany and wanted £12 to ship to the UK. If one was ordering from the US, they sell "inside the waist band" holster straps that come ready made with snaps, screws and plastic webbing. Chicago screws have an 8-32 thread, and I happened to have some 8-32 x 1" button heads that I could cut and grind down to fit inside the 15mm snaps.

I am pleased with how they all turned out. They are not pretty, and not the best finished of my work by any means, but as a gift of working tools, they will do.

Now, if someone else were to fancy making things like this, that would be great...I could point Stuart in their direction when he needs some spares!

Last edited: