I’ve received a few questions lately about how I work with leather and I haven’t talked much about it because I think there is already so much good stuff out there already but I thought I would post this up because I've not come across anyone else that sets up their thread for leather working quite the same way as I do.

Most people I've shown this to have adopted the system and it works very well for me.

It uses thinner than normal thread and avoids some of the pitfalls normally encountered while working.

I use fine untwisted linen thread about half the thickness of the final thread I need.

To wax it, I draw the thread across a lump of beeswax several times until it is well coated and feels a bit stiff.

The needles are the finest I can get that will take the thread.

I normally prepare up to 4 meters of thread to produce a 2 meter working length. ( One meter per needle which is as far as I can reach.)

This will seem like the weird bit.

Thread a needle at both ends of the thread and then tie the ends together so that you have a continuous loop of thread.

I usually use a fisherman's knot because it doesn't tend to slip with the wax as other knots often do.

When the knot is tightened and the ends trimmed off you have a very compact and neat knot.

Now stretch the part of the loop with the knot out and catch the opposite end of the loop and bring them together.

( This loop is much shorter than I would use just for illustration purposes.)

Pinch the knot and the far part of the loop together and draw the needles down to the bottom of the loops created.

If you run your fingers along the thread loops from the needles towards the knot the wax should stick the thread together somewhat creating the full width thread you are going to use.

Notice; there are no loose ends, the needles are captive on the thread and the thread passing through the eye of the needle does not form as big a "lump" to draw through the leather.

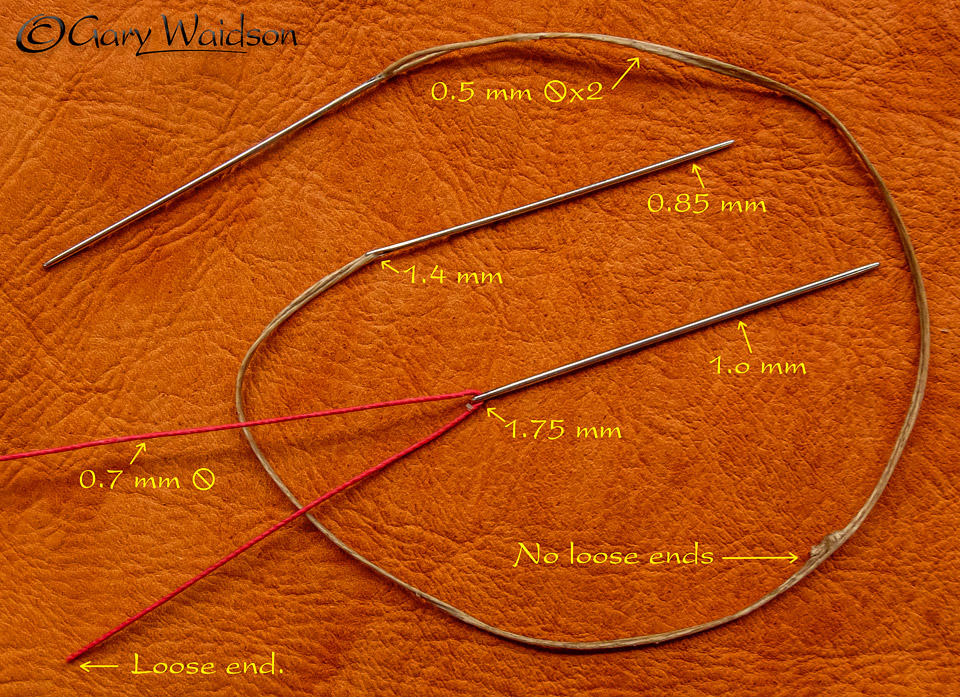

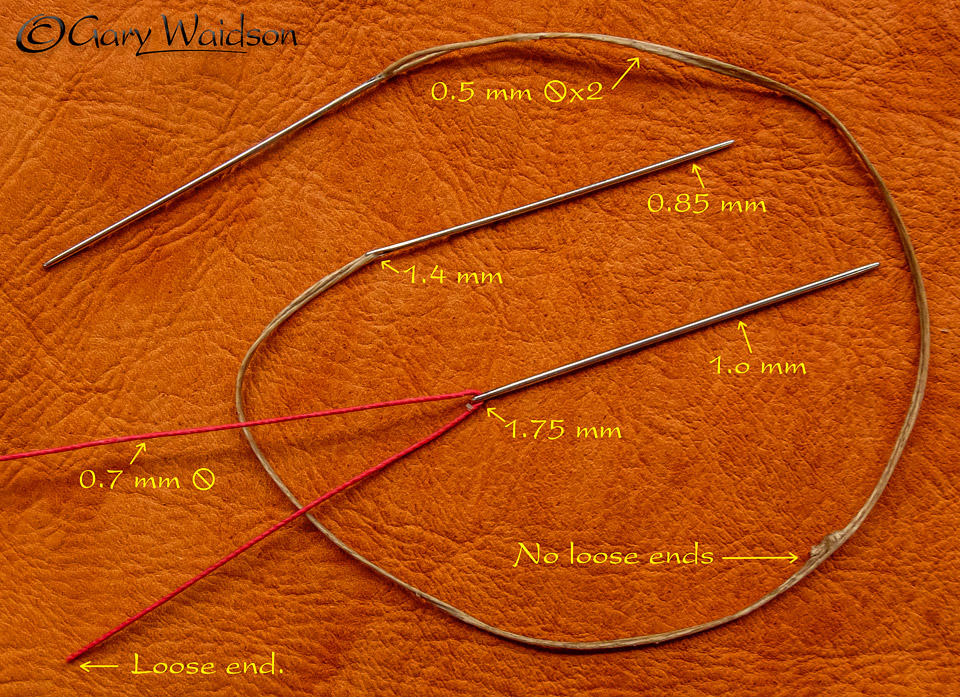

I'm not very conversant in thread guages and needle sizes but these measurements were made with a simple slip test in a micrometer to give you some idea of the advantages.

The red thread is a much more conventional leather working thread from Barbour I think.

The natural coloured thread actually delivers more thread through a smaller hole which makes stitching much easier and because there are no loose ends you don't have to worry about the needle coming off the thread.

Most people I've shown this to have adopted the system and it works very well for me.

It uses thinner than normal thread and avoids some of the pitfalls normally encountered while working.

I use fine untwisted linen thread about half the thickness of the final thread I need.

To wax it, I draw the thread across a lump of beeswax several times until it is well coated and feels a bit stiff.

The needles are the finest I can get that will take the thread.

I normally prepare up to 4 meters of thread to produce a 2 meter working length. ( One meter per needle which is as far as I can reach.)

This will seem like the weird bit.

Thread a needle at both ends of the thread and then tie the ends together so that you have a continuous loop of thread.

I usually use a fisherman's knot because it doesn't tend to slip with the wax as other knots often do.

When the knot is tightened and the ends trimmed off you have a very compact and neat knot.

Now stretch the part of the loop with the knot out and catch the opposite end of the loop and bring them together.

( This loop is much shorter than I would use just for illustration purposes.)

Pinch the knot and the far part of the loop together and draw the needles down to the bottom of the loops created.

If you run your fingers along the thread loops from the needles towards the knot the wax should stick the thread together somewhat creating the full width thread you are going to use.

Notice; there are no loose ends, the needles are captive on the thread and the thread passing through the eye of the needle does not form as big a "lump" to draw through the leather.

I'm not very conversant in thread guages and needle sizes but these measurements were made with a simple slip test in a micrometer to give you some idea of the advantages.

The red thread is a much more conventional leather working thread from Barbour I think.

The natural coloured thread actually delivers more thread through a smaller hole which makes stitching much easier and because there are no loose ends you don't have to worry about the needle coming off the thread.