Well maybe, C_Claycomb. For a start: "It still cuts, doesn't it?" is hardly a criterion of quality assessment on a very expensive knife. As you know, these things are as much jewels as they are cutlery, and, like our OP, people put a lot into saving for them.

True, but Woodsorrel specifically asked if this was a

performance and durability issue, and went on to ask if makers here could weigh in and confirm that this is just a cosmetic issue, which implies that he is not worried about the cosmetics, or wants this to be a jewel-like draw queen. If the the original question had been whether this was acceptable from an aesthetic point of view, I would have said send it back, not because of the heights on the sides, but because the tip looks odd, and it would bother me in an expensive draw queen.

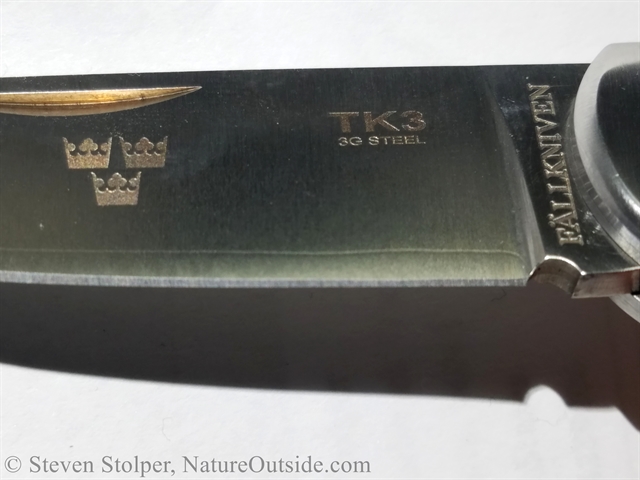

And, just because Erik Hjortberger (who, from your post, sounds a right chip off the old block) says it is OK, doesn't mean its OK. I mean, as honcho at Fallkniven, he would say that wouldn't he? Further: I just looked at some of the various Fallkniven folders and fixed blades I have and the grinds are all fine on them too. We know that the soft steel lamination is to protect the peceived brittleness of the 3G and VG10 steel in the cold, I get that. It is not an aesthetic imperative there. Nevertheless, evenness seems attainable. Why not hit it every time and reject or sell off as seconds those that aren't spot on?

See threads linked in previous post. People do see variation in lamination lines in other Fallkniven knives. With manufacturing processes there is usually a tolerance bell curve, you reject the outliers and keep the ones that are near the middle, nominal, values. If the process has a wider tolerance it makes no difference that some items come in perfect, there will still be a higher proportion of outliers than if the process is tight. Welding metals tends to be a less precise business than machining them. I don't know about Fallkniven's process, but I do know a little about design and manufacture of precision parts, and what Fallkniven have said about cost increases tallies with my professional experience.

Also, Spyderco sell laminated blades. I have seen a bunch, am a fusspot, and the grind lines seem just fine on them.Likely manufactured by the same company, too

It may just be that Spyderco's QC is more fiercely rigorous and requiring than Fallkniven's.

Spyderco can have the same thing with their laminations, threads going back over a span of years, and recently too.

Particualrly this one -

https://www.spyderco.com/forumII/viewtopic.php?p=1242436#p1242436

https://www.bladeforums.com/threads/sb-stretch-uneven-laminate-lines.1306678/

https://www.bladeforums.com/threads/uneven-laminate-lines.1418391/

http://www.spyderco.com/forumII/viewtopic.php?t=22495

Now for the funny part. I don't really like Fallkniven knives all that much! I want to, and I have recommended the F1, but I don't like the cladding on their fixed blades, I don't like how thick their fixed blades are, and I don't like the ergonomics of most of their knives. I have handled a few of their folders, including doing a re-grind and spruce up of a PXL folder (laminated blade) and could find little to recommend it to me in terms of weight, design, or ergonomics, and the user/abuser of it had managed to break the pocket clip and shear off several millimetres of bevel in a way I have not seen before.

If my posts come off like a full throated defence of Fallkniven, that is not my intent and I am sorry if it came out that way. I was only trying to point out:

Lamination variation is normal, is unlikely to cause performance problems, has been going on a long while and it is not reasonable to expect perfection in that particular process for the price of this product. This is all about the engineering, not about the brand.

Chris