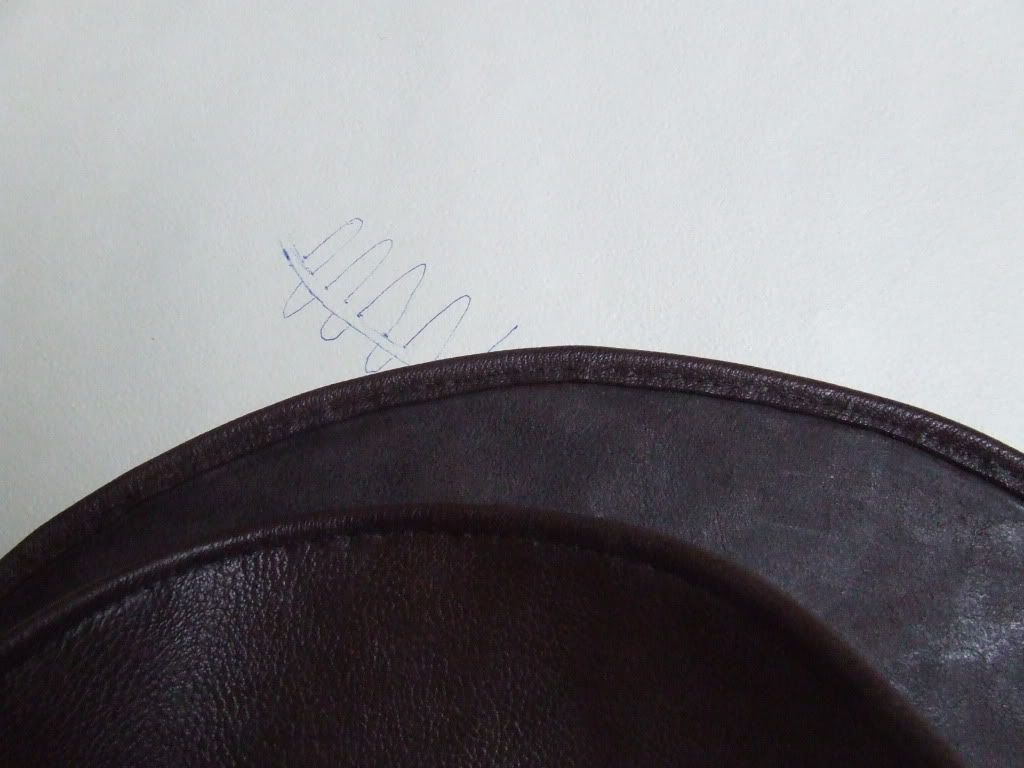

I was in the process of making yet another leather hat ( as seen on another thread) but wasn't quite pleased with a few things so I took the bugger apart & since there are often requests for a tutorial on how to make such a hat I thought I'd take this opportunity to try & put together a 'how to'. A few months ago after sending several emails to photobucket I managed to recuperate the 'old version' ....much more user friendly but now they are trying to twist my arm to switch to their new format by depriving me of certain functions so this has giving me added impetus to start the thread now, before the hat is finished, & I'll add further photos (photobucket permittting) & explanations as the hat progresses.

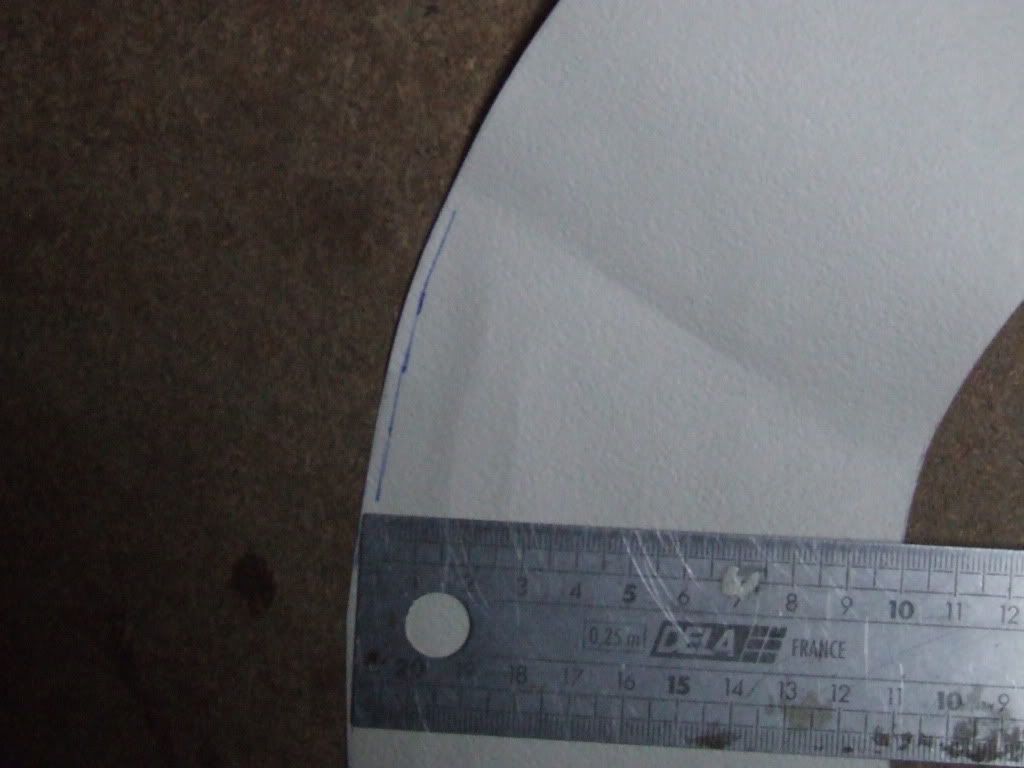

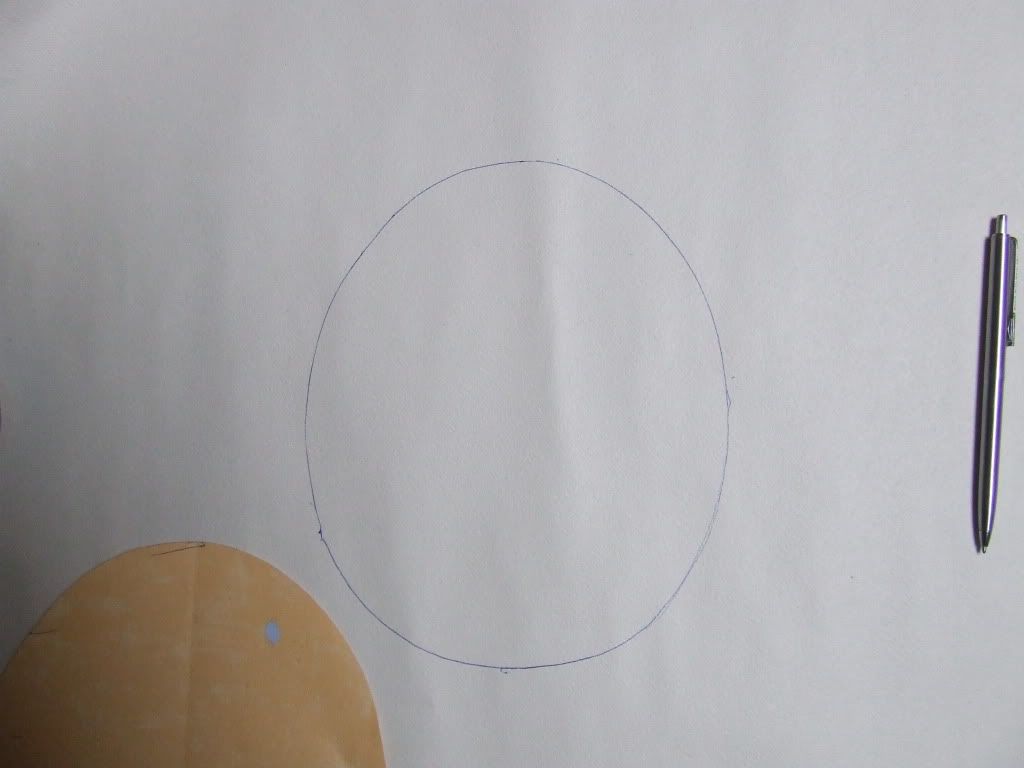

First of all we have to make a pattern. I use wall paper as I have it & it has sufficient stiffness but any thickish paper or thin card would do.

& it has sufficient stiffness but any thickish paper or thin card would do.

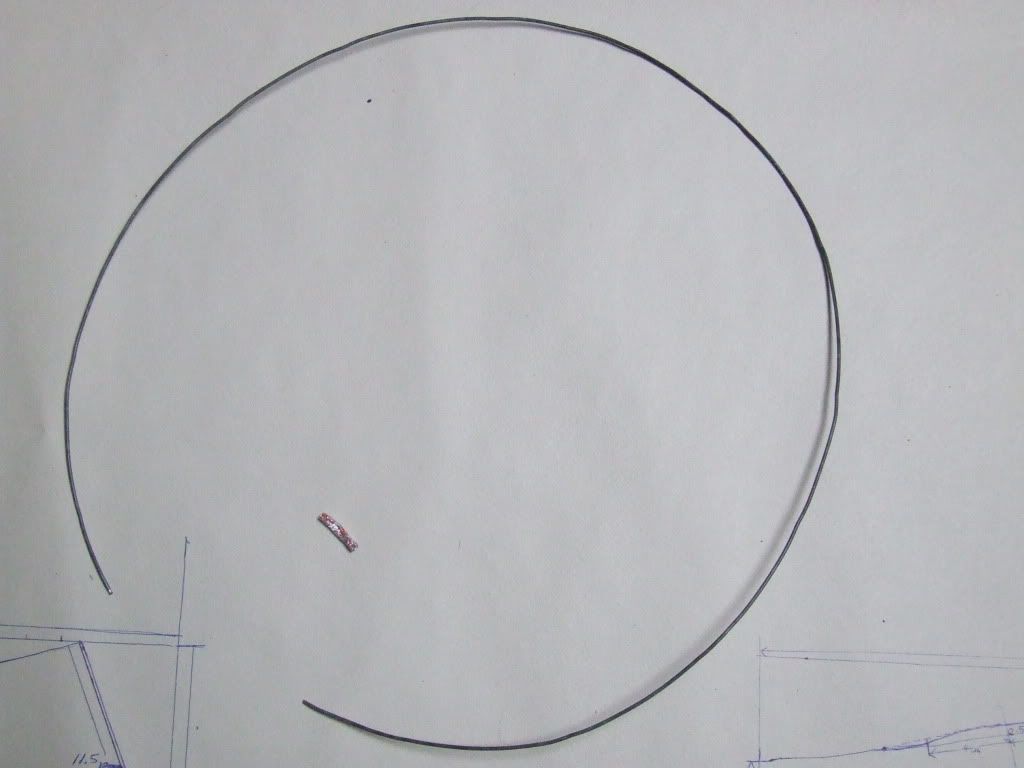

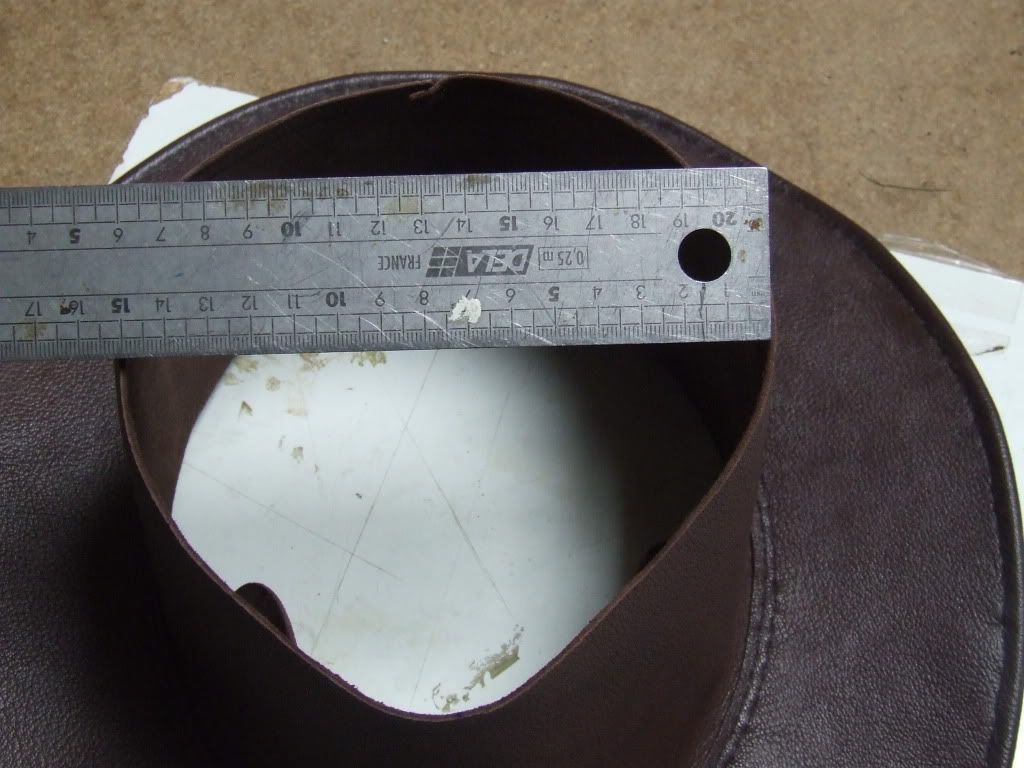

You need to measure your head size, if you haven't got a soft tape measure, a piece of string or paracord can be used, wrap it around your noggin about an inch above the ears & eyebrows, then lay it flat & measure it. I've made quite a few hats in the past so I have my usual pattern which I use each time but I'm afraid you'll have to work out the head hole size yourselves by trial & error as there isn't an easy solution .......I think.

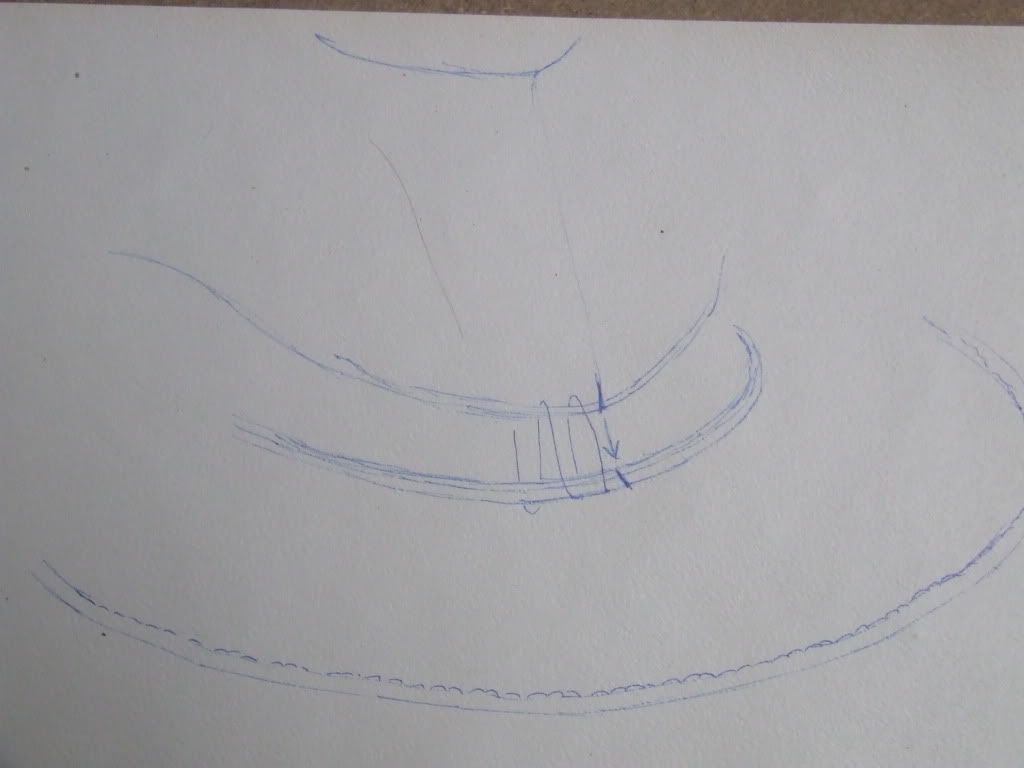

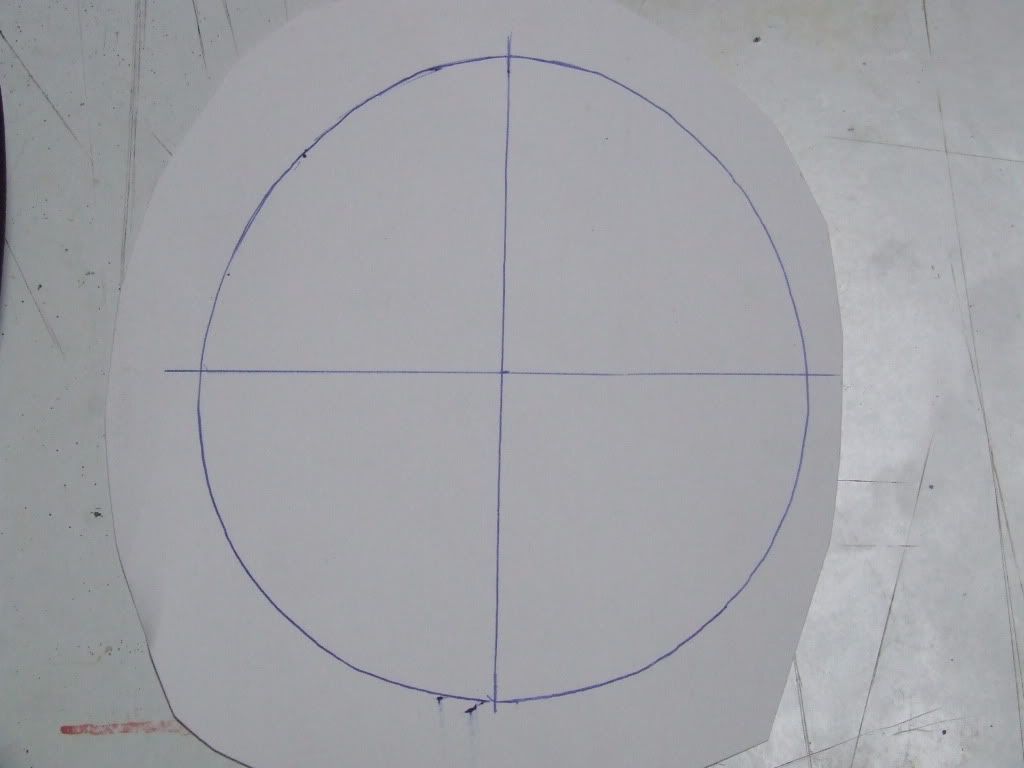

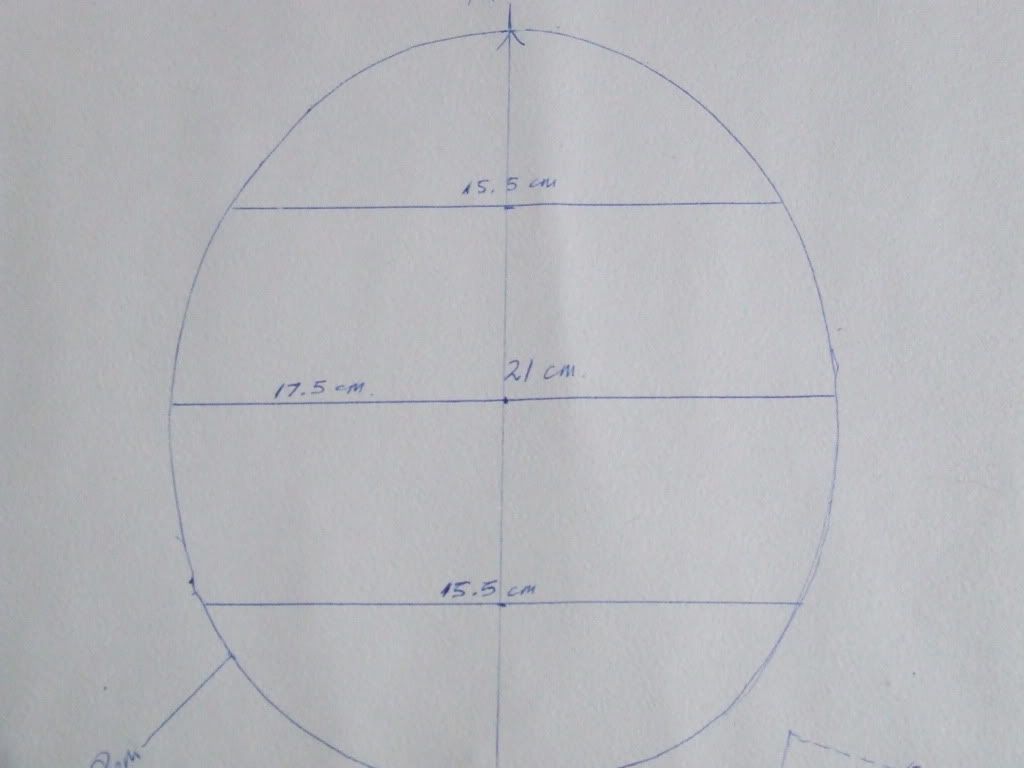

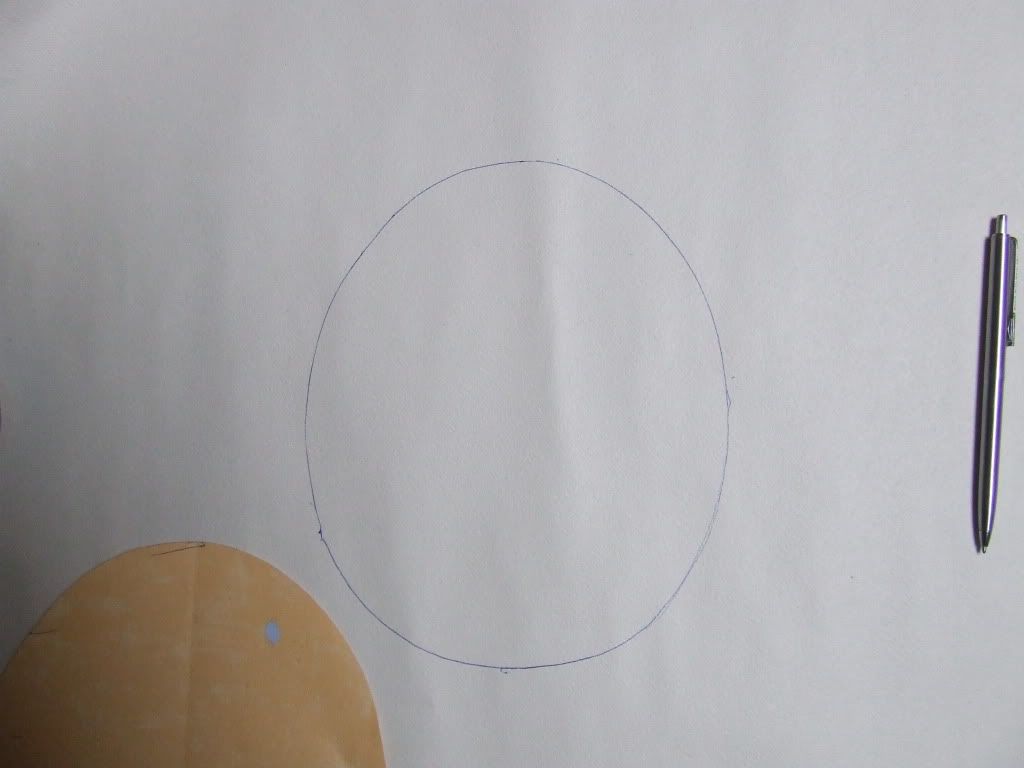

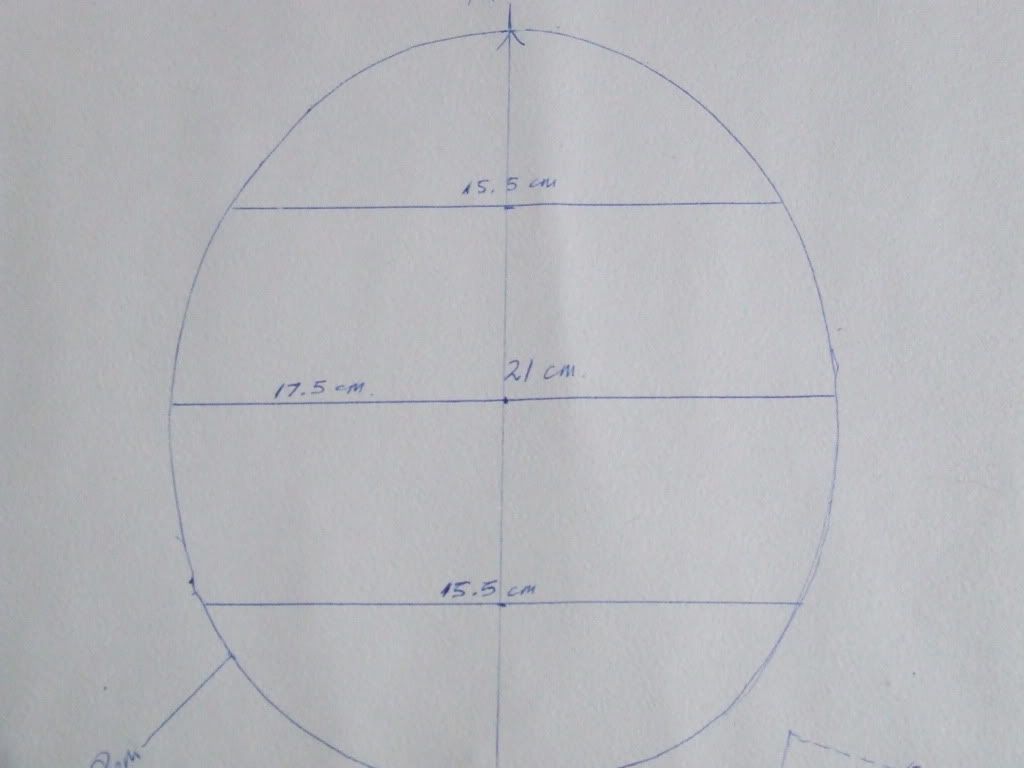

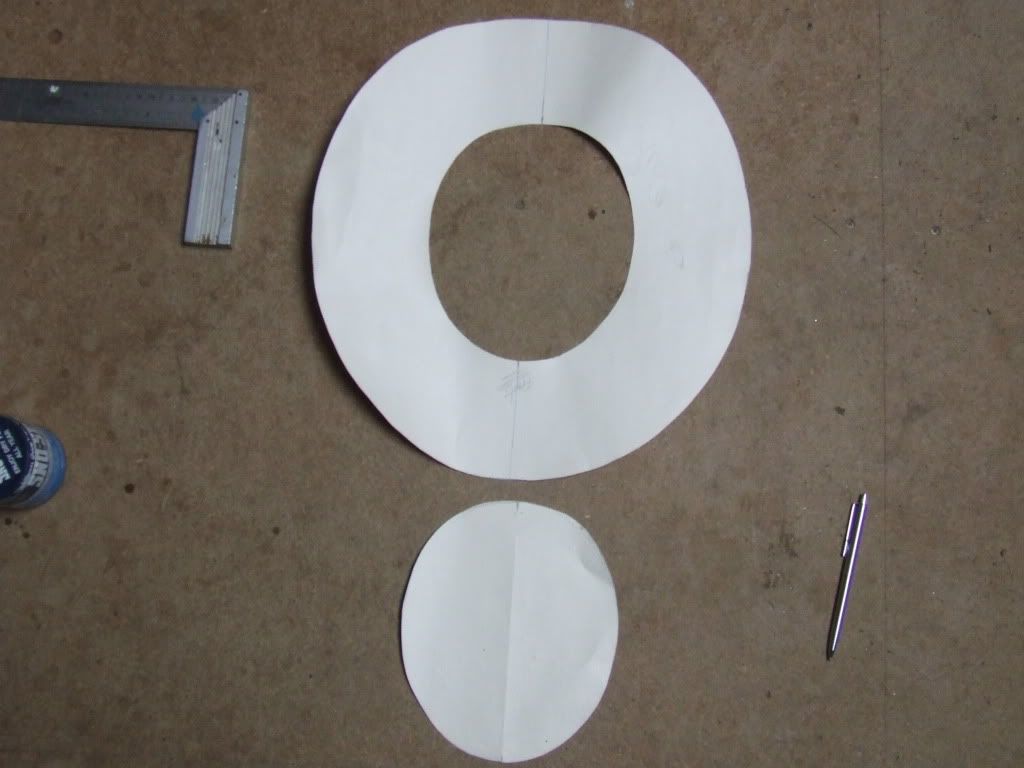

First thing to do is draw the center hole, most of us have oval heads so bear that in mind.......you don't want a circle.

Just to give you an idea I'm a 58 cm head & the dimensions of my hole are as follows,

are as follows,

That's 21 cm long & 17.5 cm across at the middle.

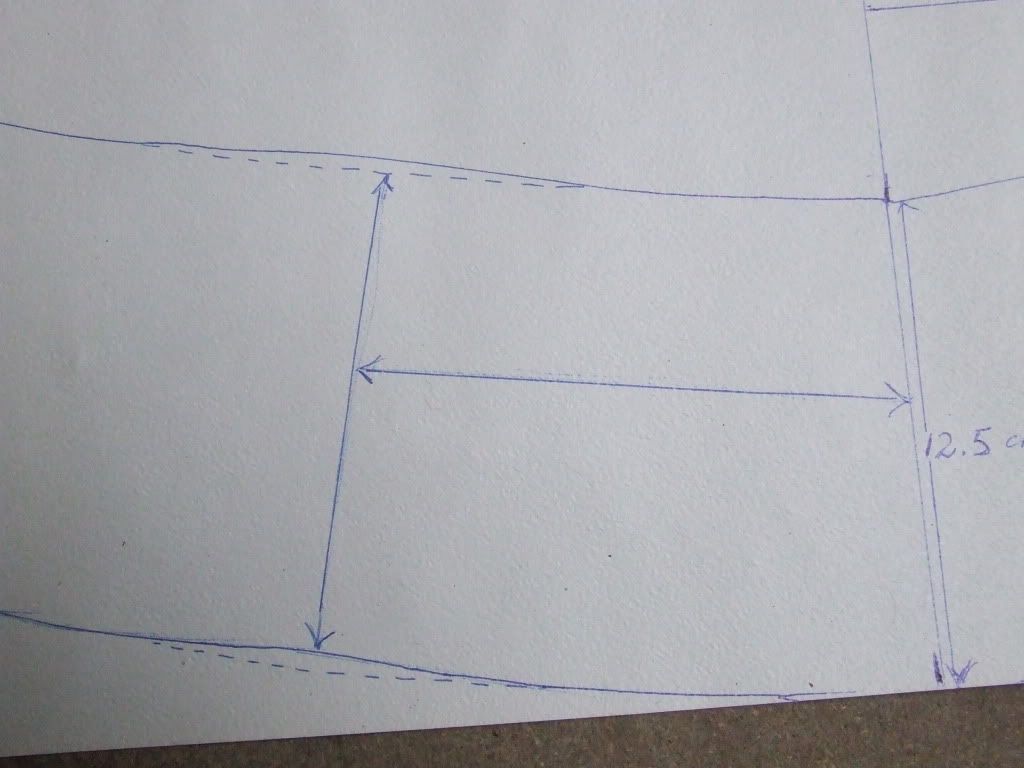

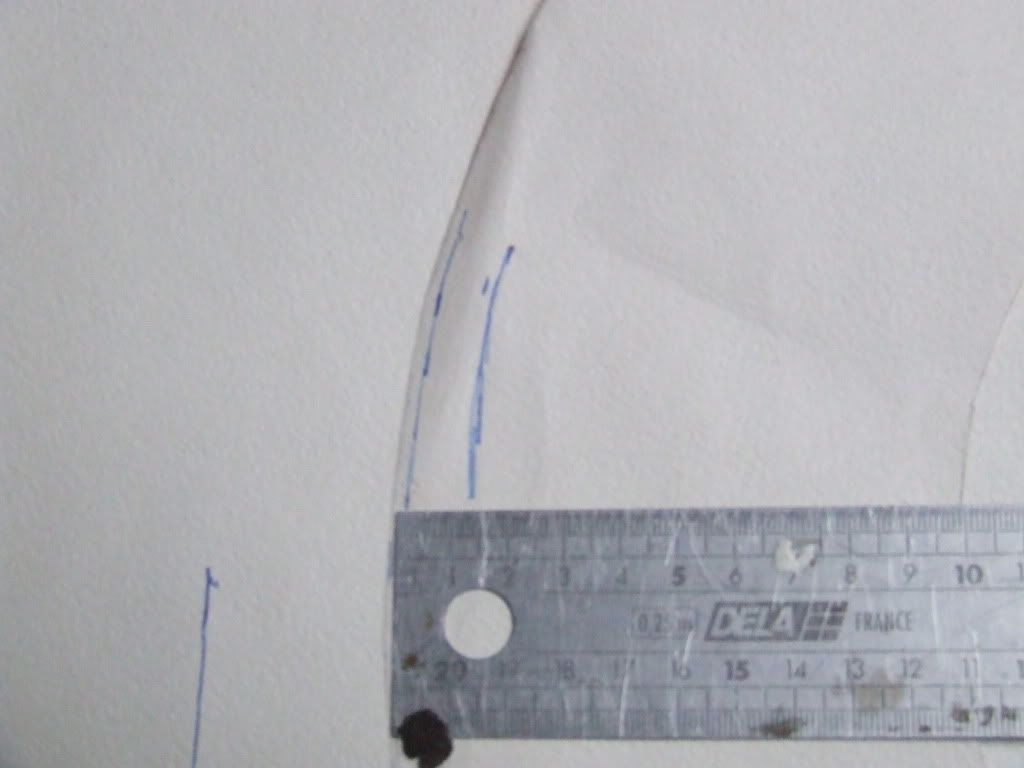

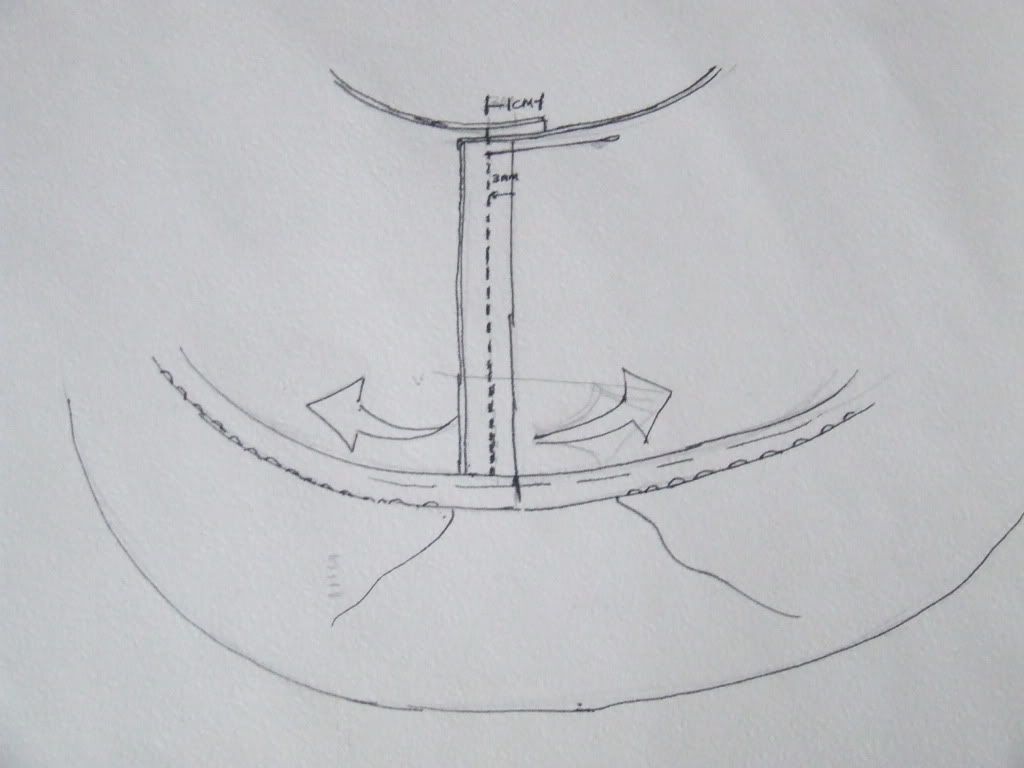

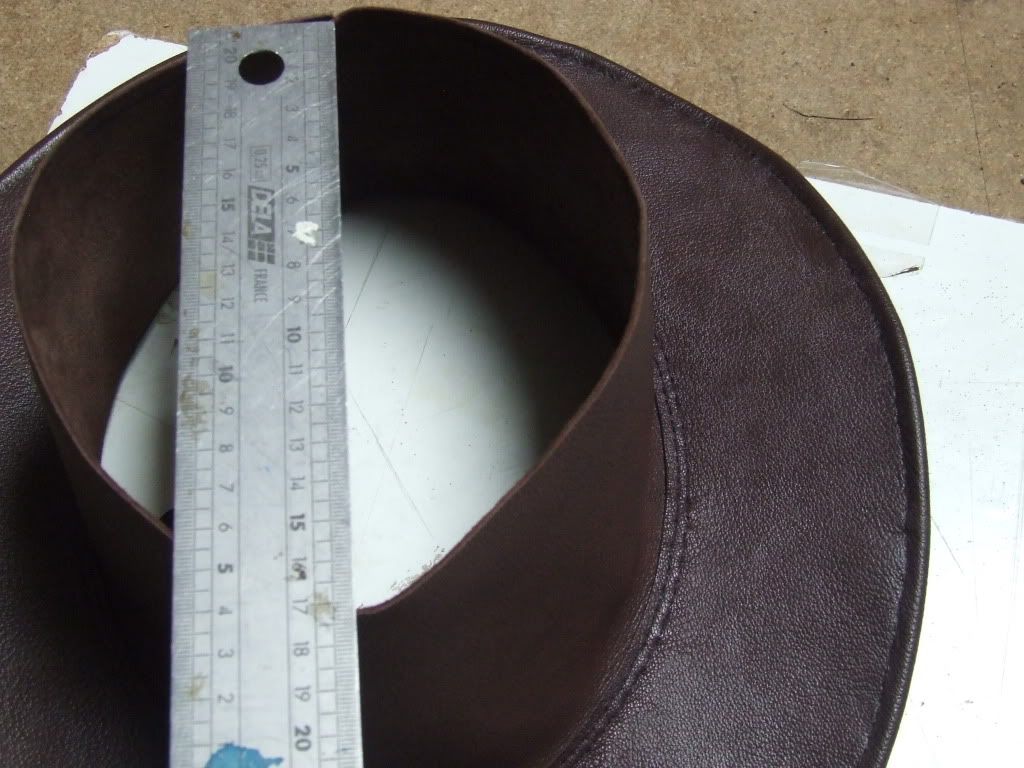

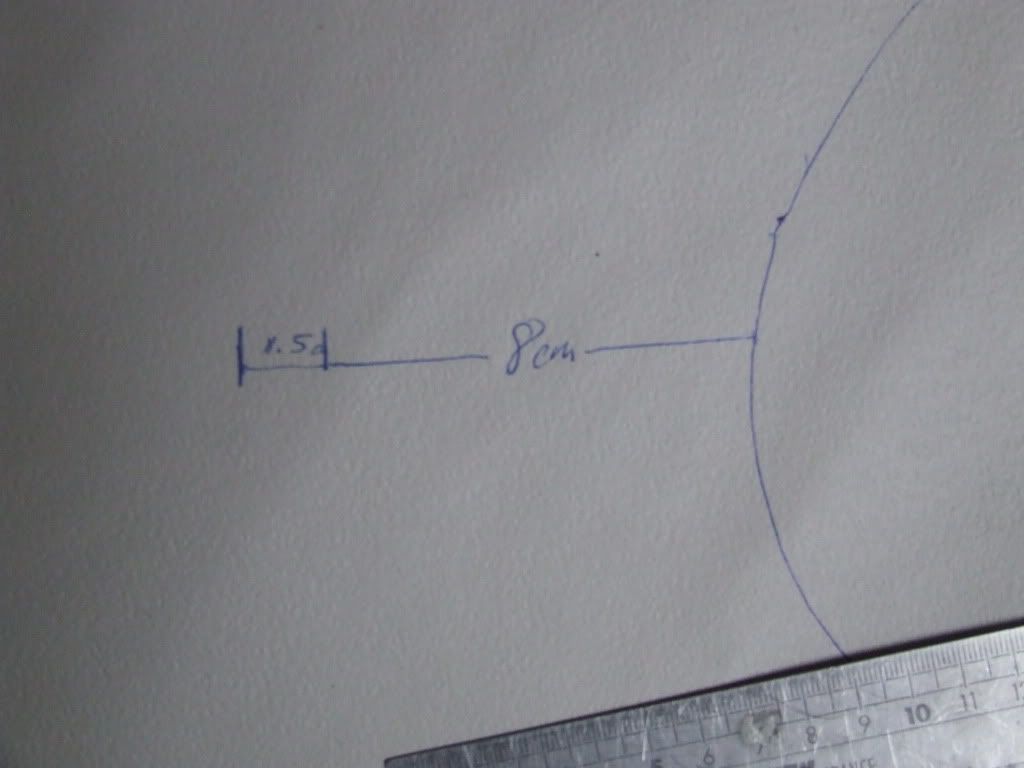

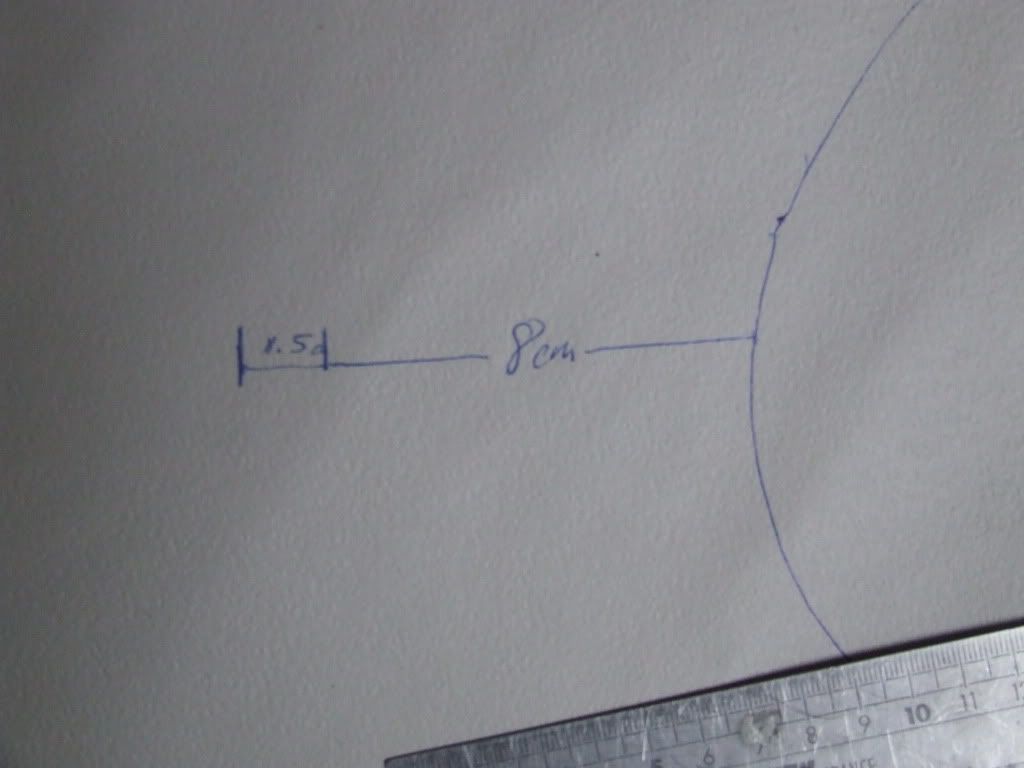

Brim width is a matter of personal choice, some prefer narrow brims other's wider & it's up to you how wide you want the brim. For this hat I've chosen an 8 cm brim, which will give good sun & rain protection & not get in the way.

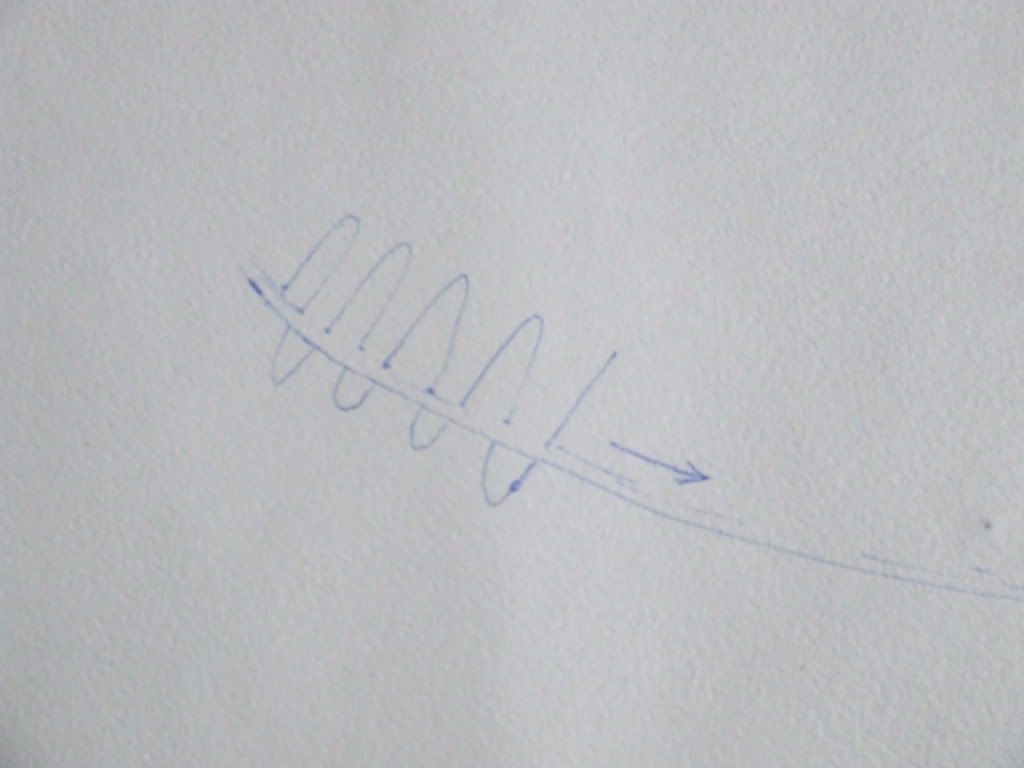

What ever the width you choose you must add on a further 1.5 cm which will be folded over the brim wire. e.g.

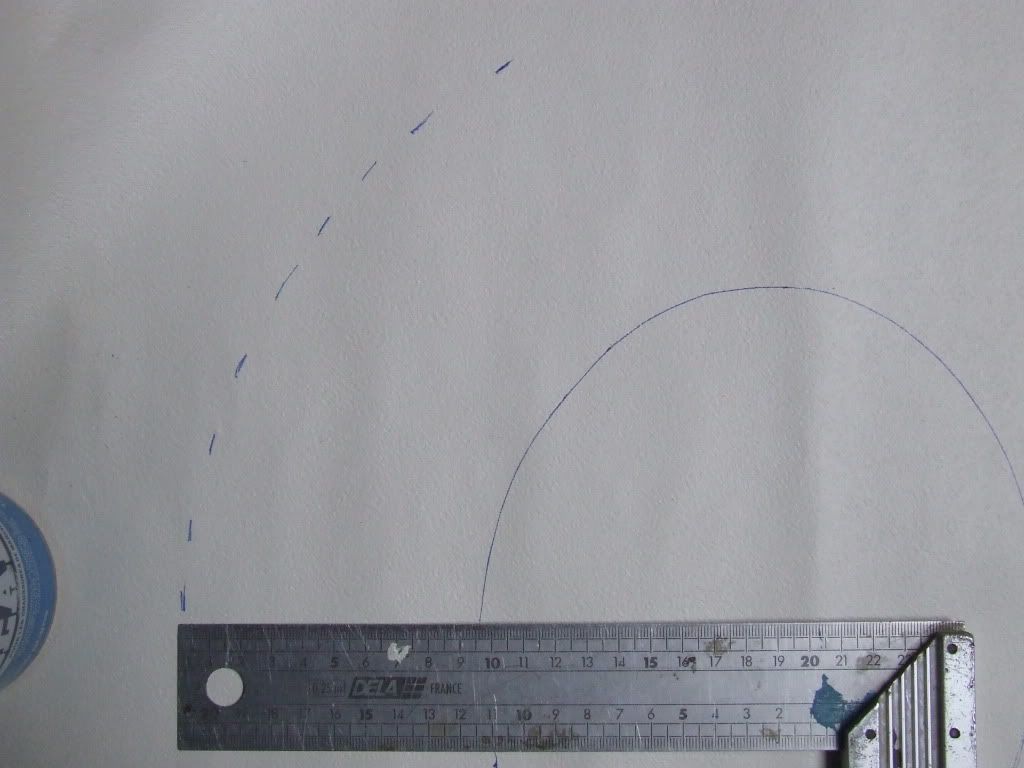

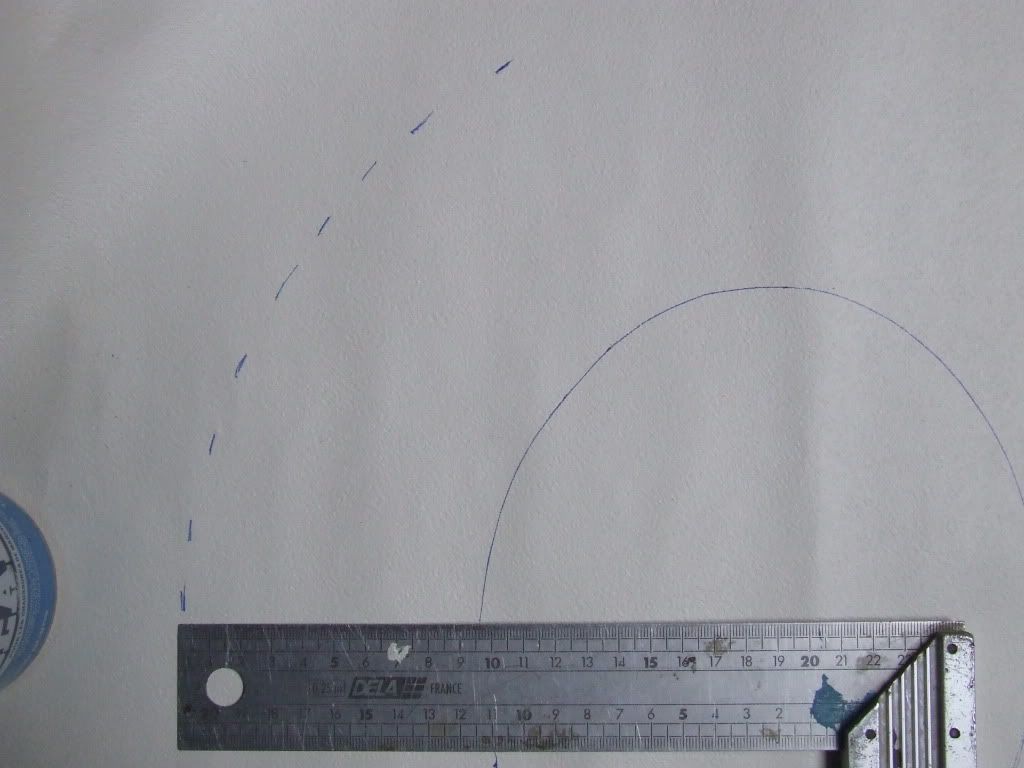

Once you've decided on the brim width simply draw a series of dots or dashes leading off from your drawn center hole like thus

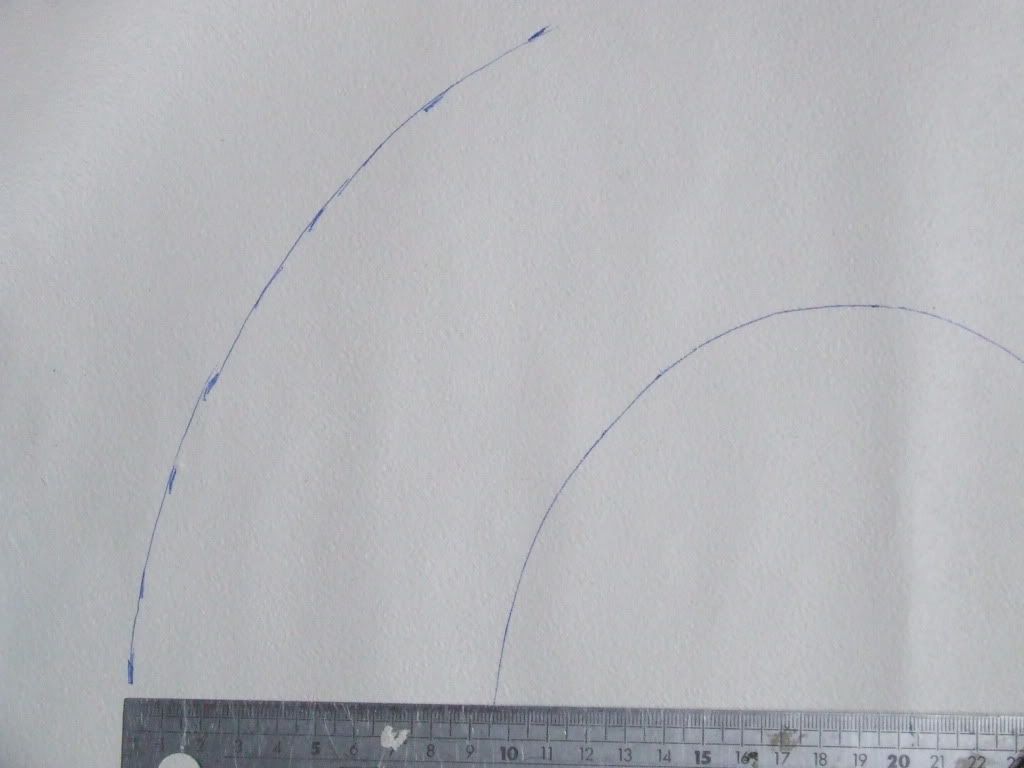

then join them up all around

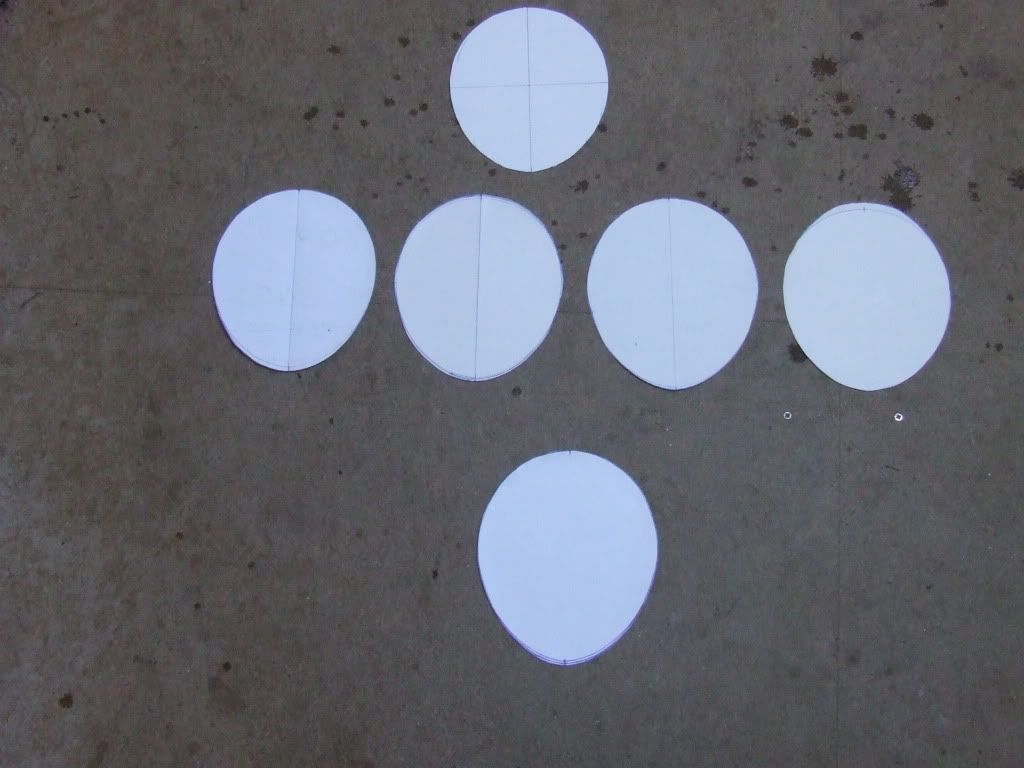

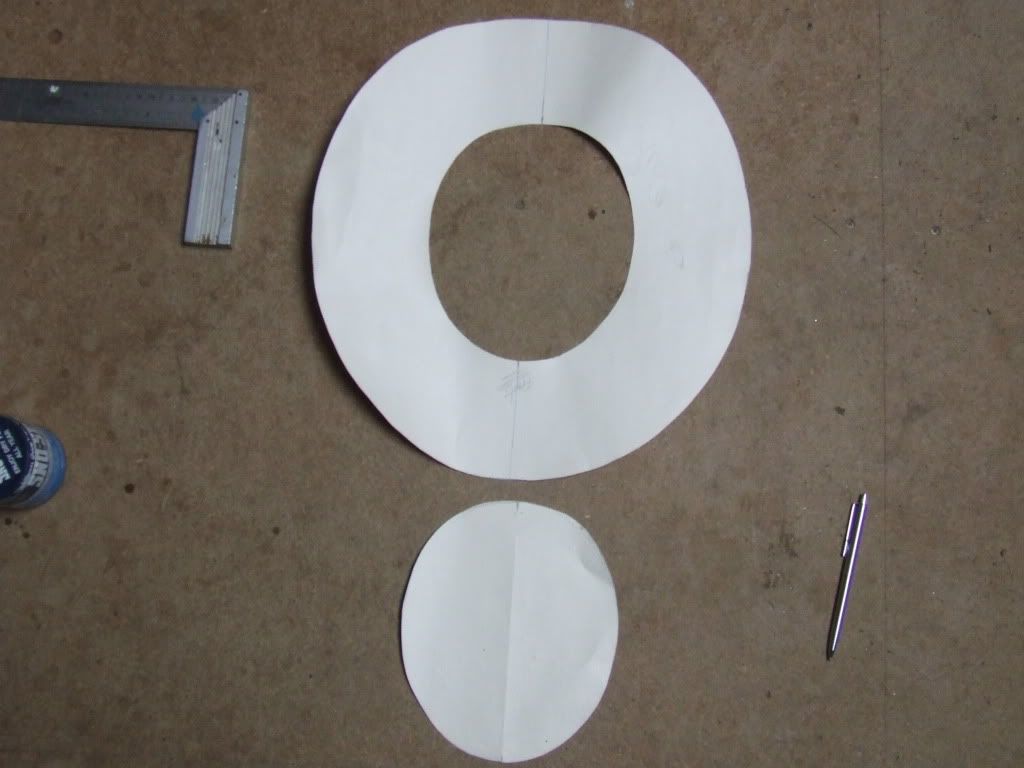

Now you can cut them out with a pair of scissors unless you have a sure hand with a cutter

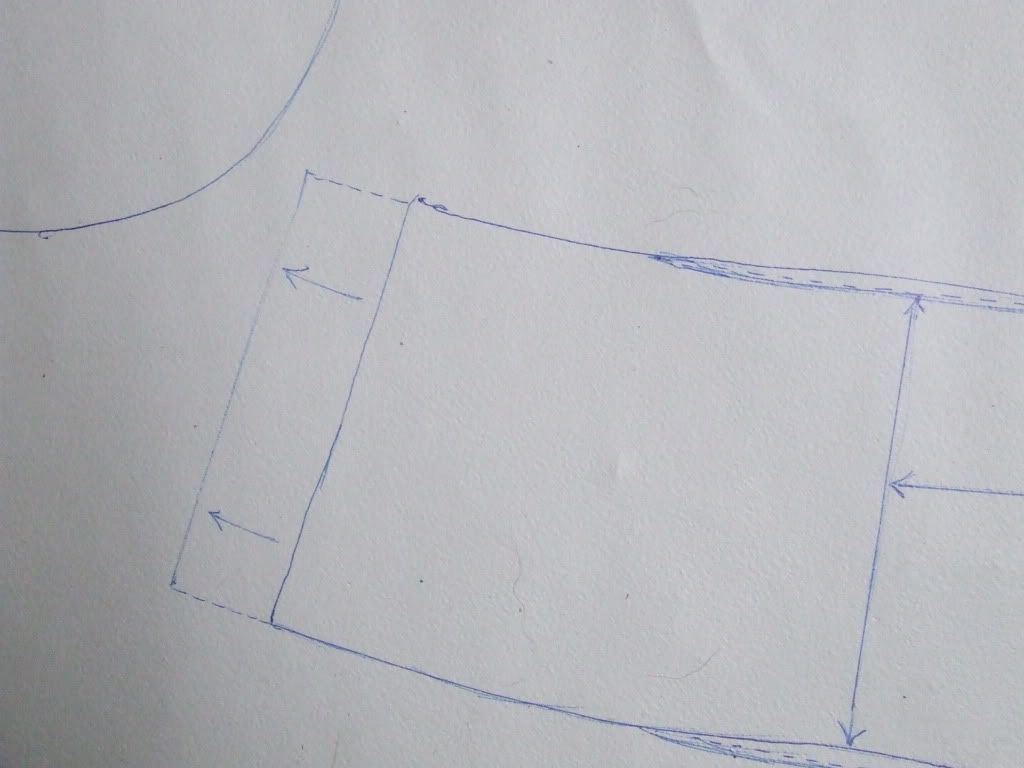

So now you have your brim template.... the center bit will be the hat's top

You'll need to mark the exact center front 'n' aft

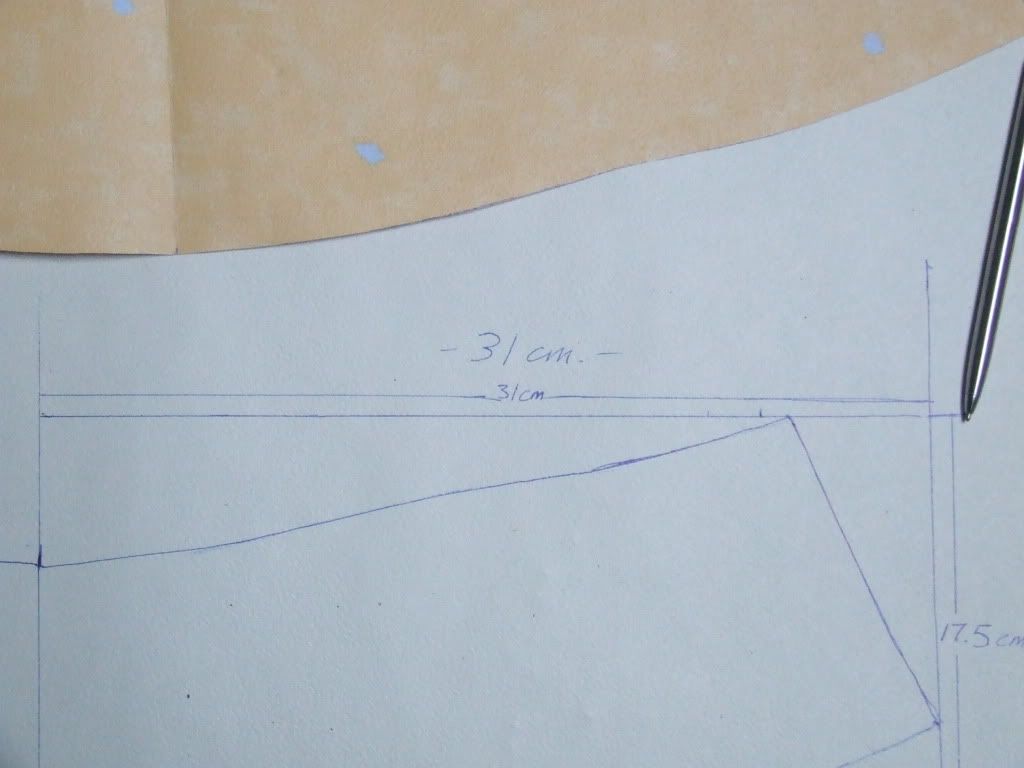

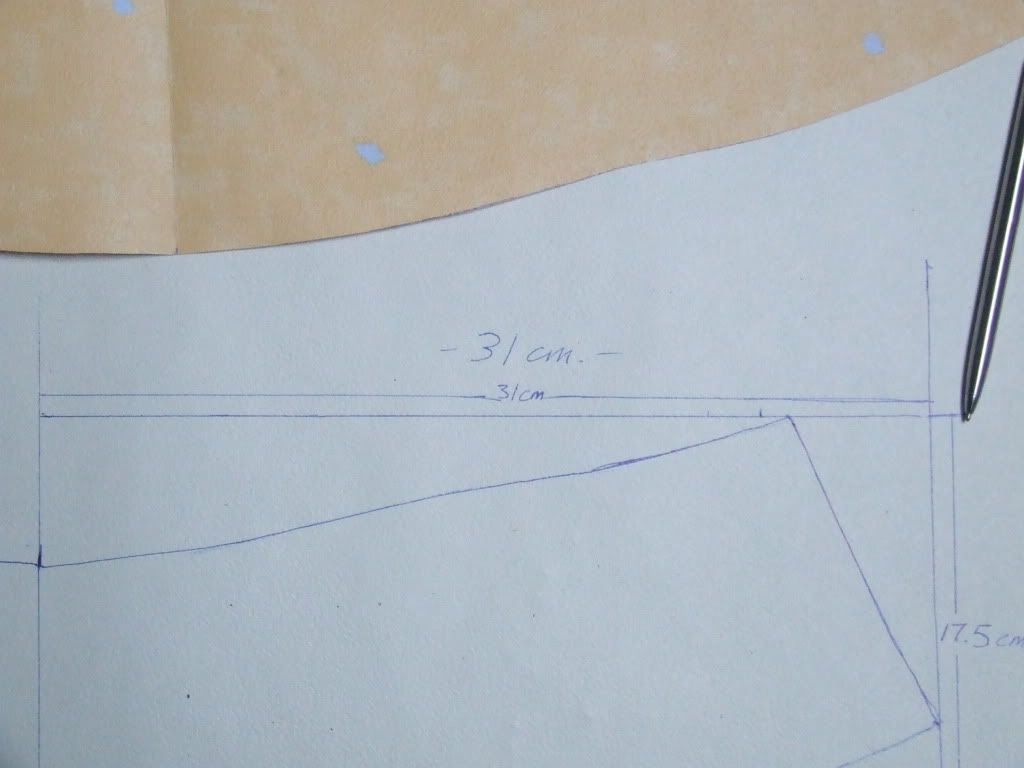

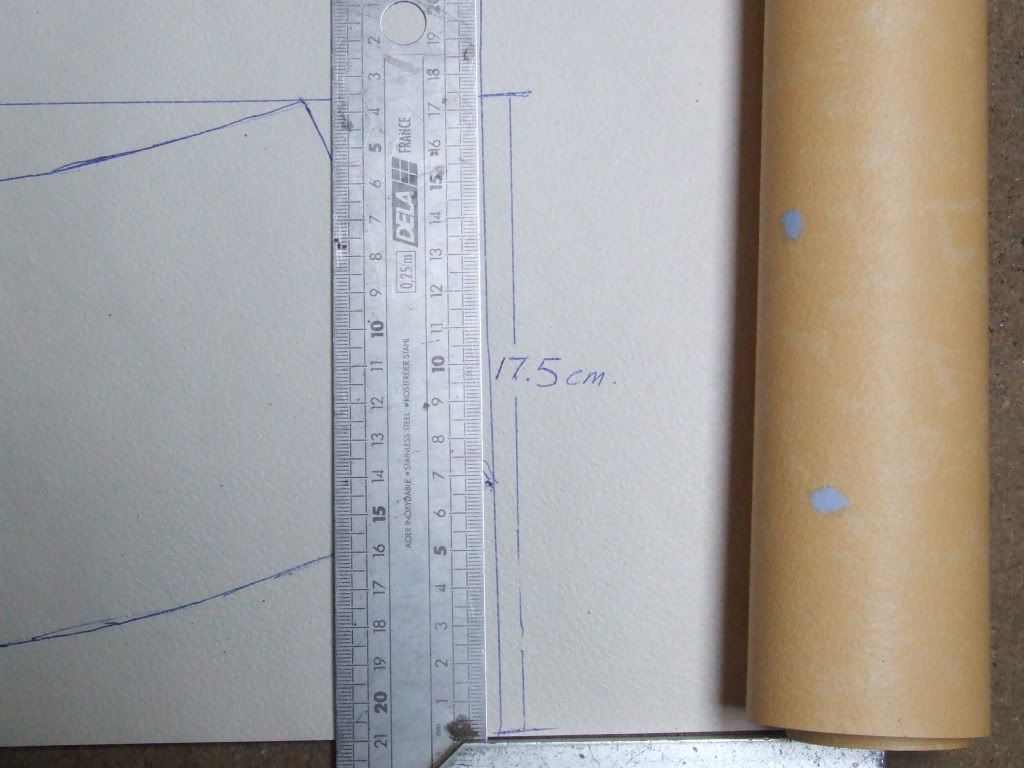

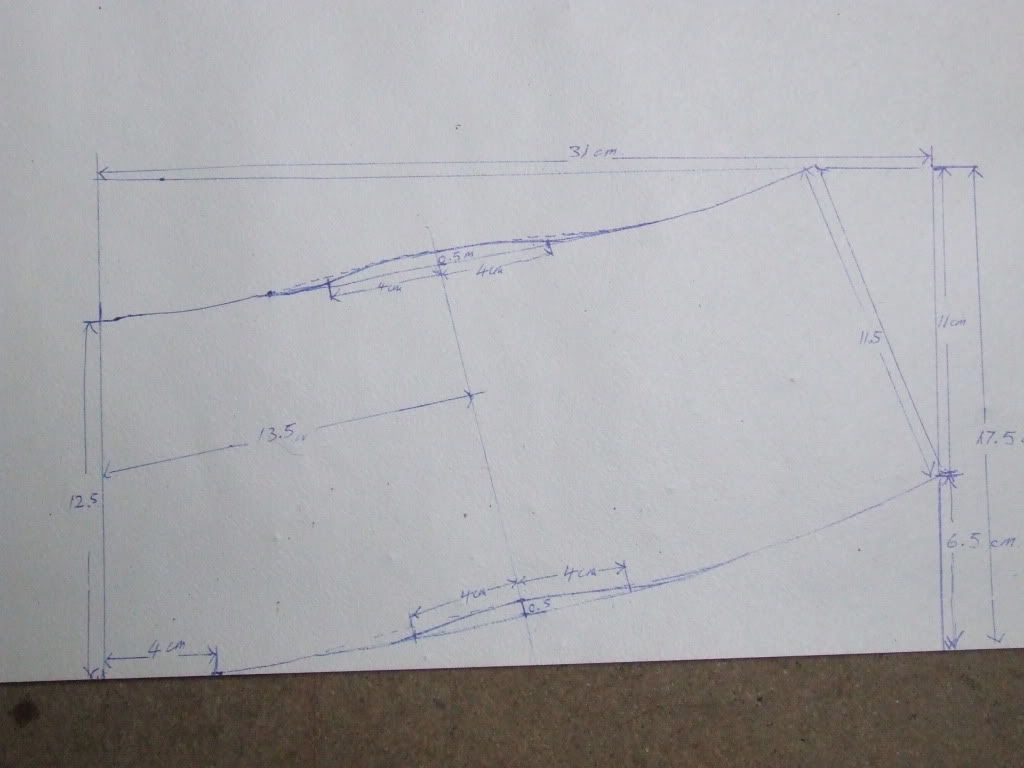

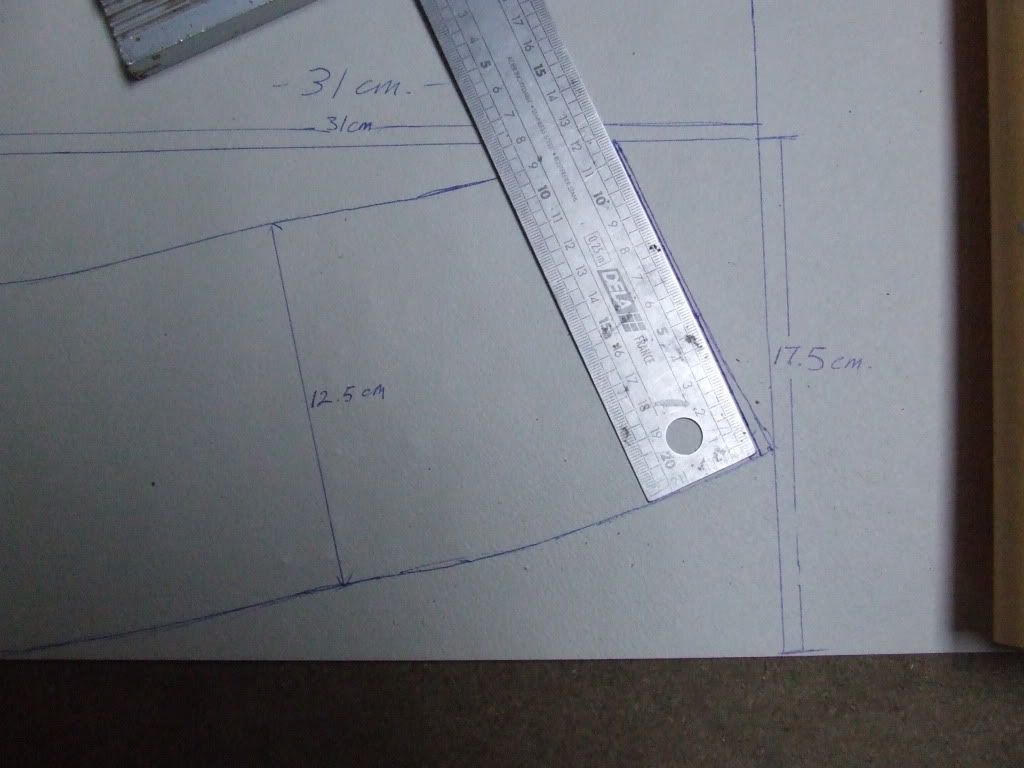

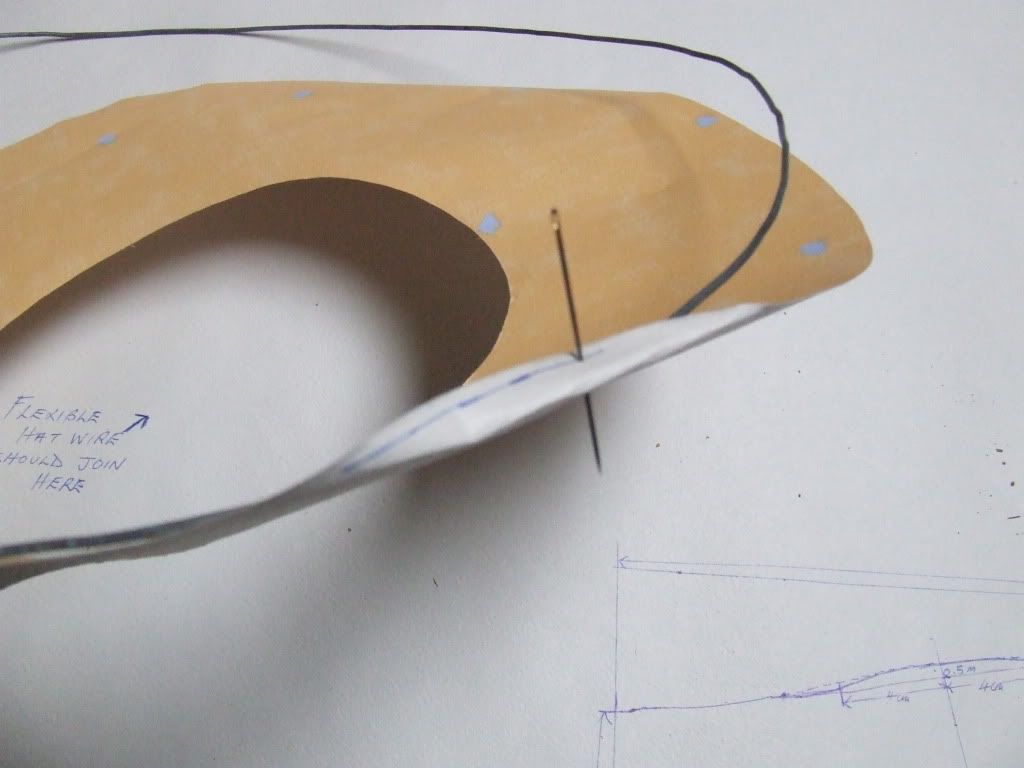

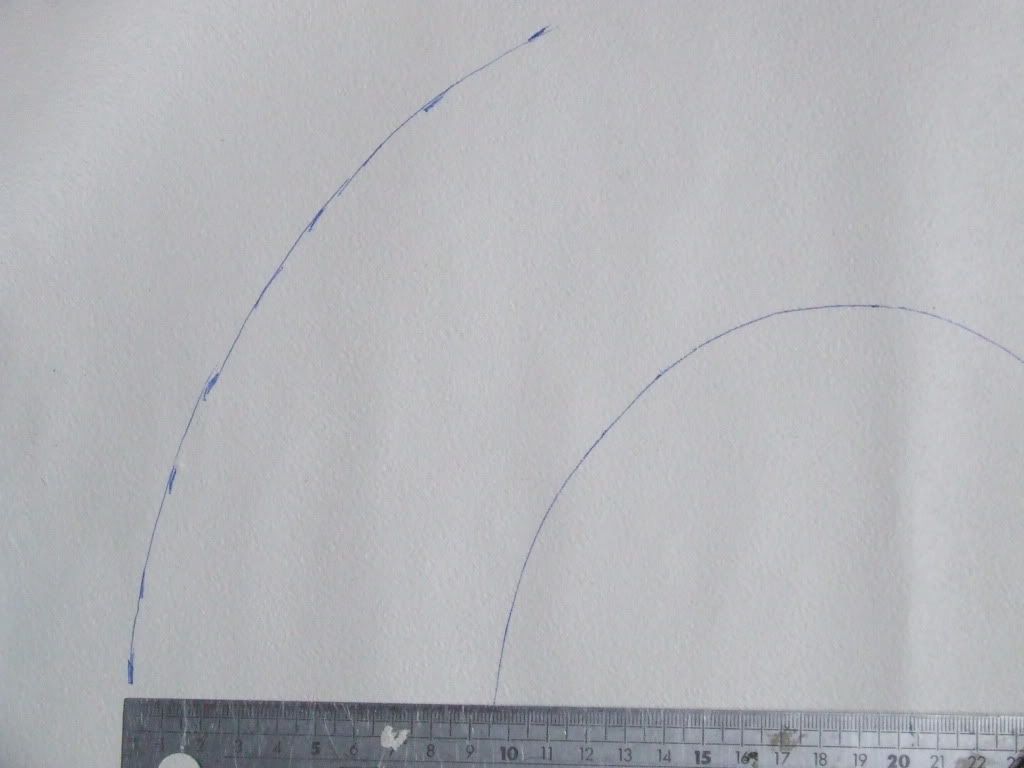

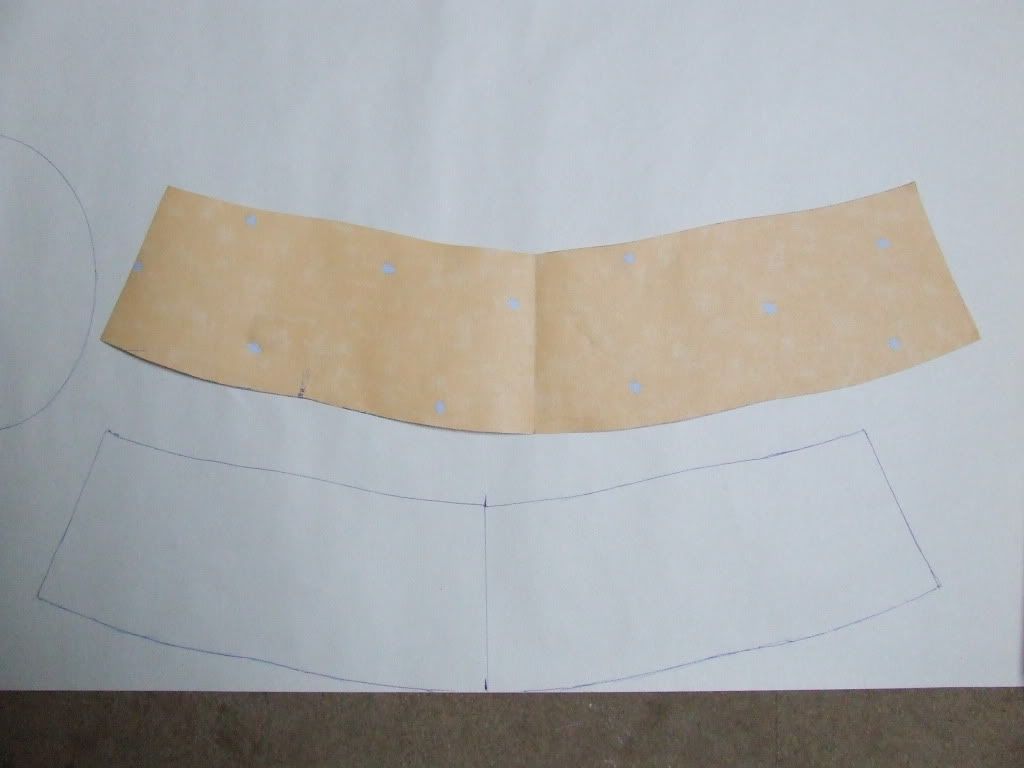

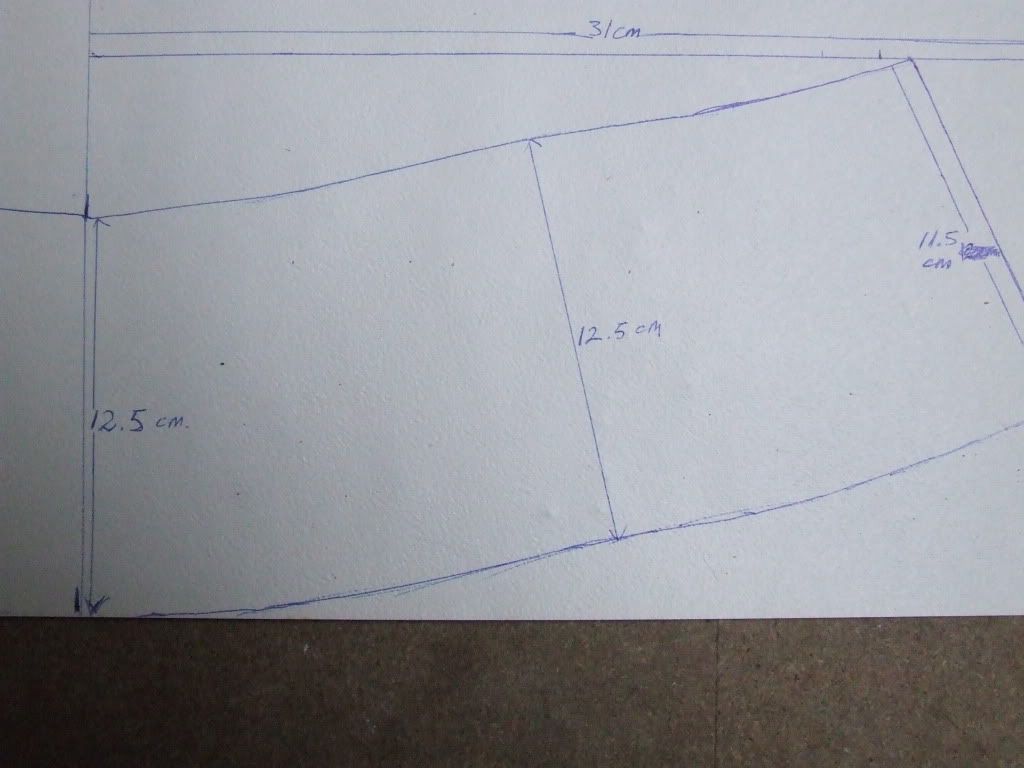

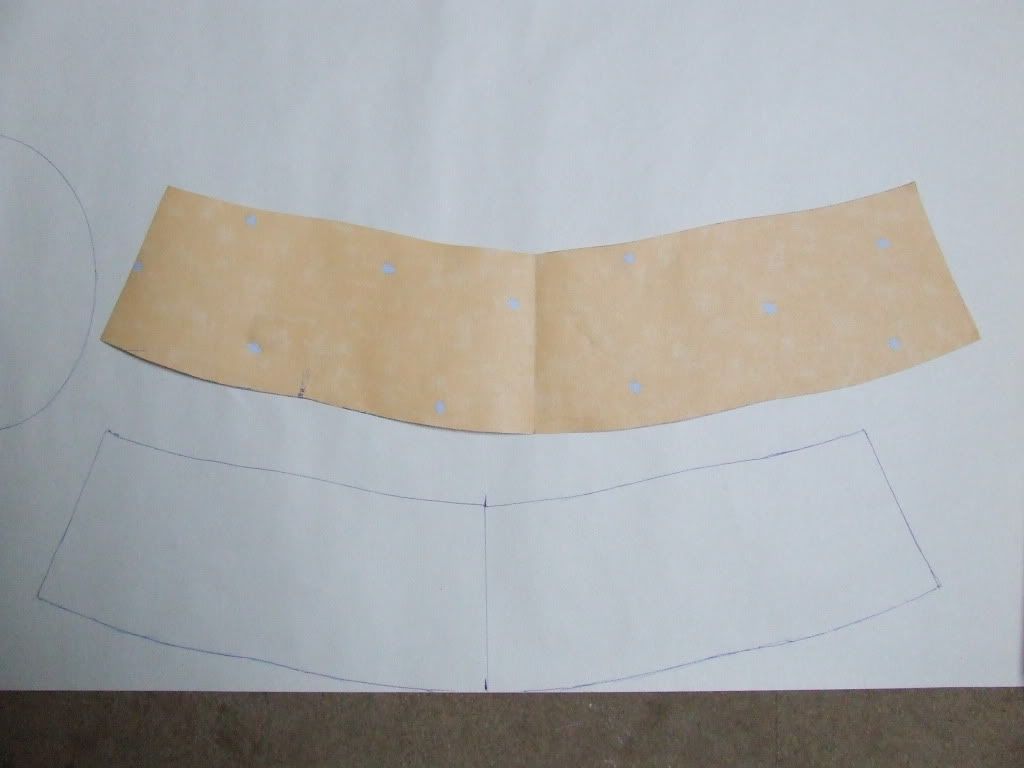

Now the crown & this is where it's gets complicated I usually experiment with a different style of crown each time & I"ve settled for the following for this one.

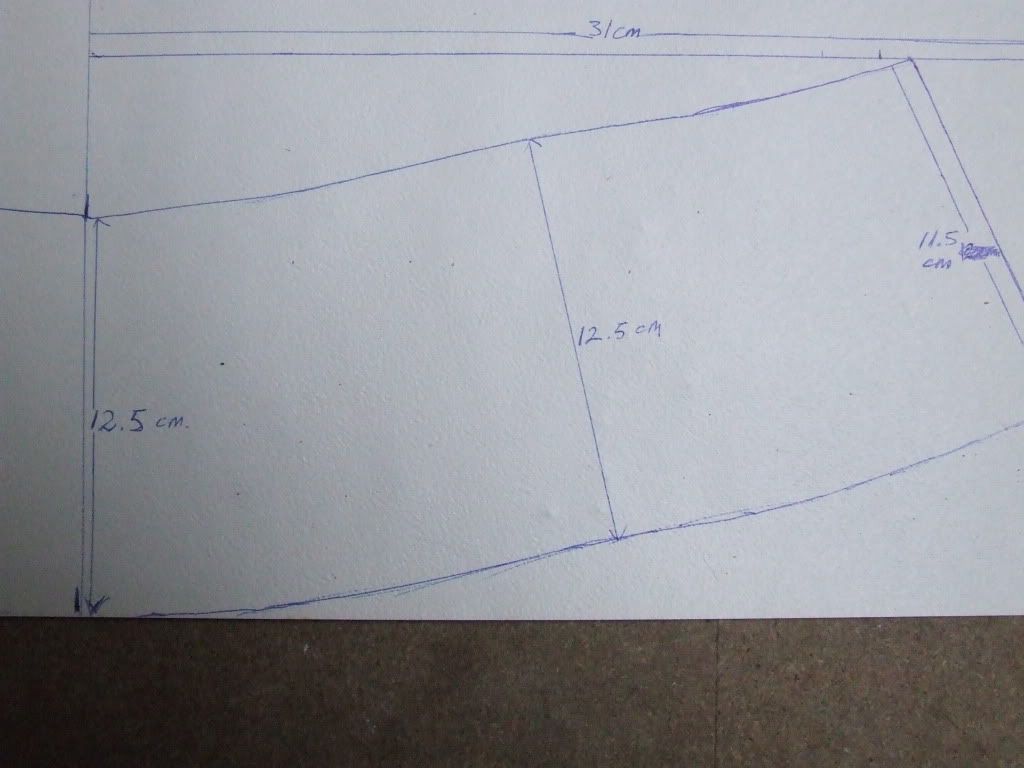

Hopefully you can see that there is a slight hump about midway on each side, I want this hat to have a soft slope so I'm aiming for a crown with a 10 cm crown at the front & dropping off to 9cm at the back. Again this is just to give you an idea as you may wish for a higher or lower crown.These are the measurements I've used.

First of all we have to make a pattern. I use wall paper as I have it

You need to measure your head size, if you haven't got a soft tape measure, a piece of string or paracord can be used, wrap it around your noggin about an inch above the ears & eyebrows, then lay it flat & measure it. I've made quite a few hats in the past so I have my usual pattern which I use each time but I'm afraid you'll have to work out the head hole size yourselves by trial & error as there isn't an easy solution .......I think.

First thing to do is draw the center hole, most of us have oval heads so bear that in mind.......you don't want a circle.

Just to give you an idea I'm a 58 cm head & the dimensions of my hole

That's 21 cm long & 17.5 cm across at the middle.

Brim width is a matter of personal choice, some prefer narrow brims other's wider & it's up to you how wide you want the brim. For this hat I've chosen an 8 cm brim, which will give good sun & rain protection & not get in the way.

What ever the width you choose you must add on a further 1.5 cm which will be folded over the brim wire. e.g.

Once you've decided on the brim width simply draw a series of dots or dashes leading off from your drawn center hole like thus

then join them up all around

Now you can cut them out with a pair of scissors unless you have a sure hand with a cutter

So now you have your brim template.... the center bit will be the hat's top

You'll need to mark the exact center front 'n' aft

Now the crown & this is where it's gets complicated I usually experiment with a different style of crown each time & I"ve settled for the following for this one.

Hopefully you can see that there is a slight hump about midway on each side, I want this hat to have a soft slope so I'm aiming for a crown with a 10 cm crown at the front & dropping off to 9cm at the back. Again this is just to give you an idea as you may wish for a higher or lower crown.These are the measurements I've used.

Last edited: