Update......

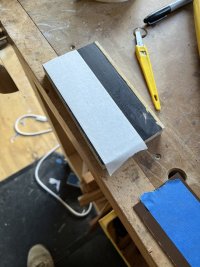

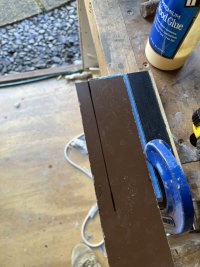

I've buggered it up. I only have hand tools and while the carbon saw blades eat through the G10 easily enough, they bend and I can't seem to saw it straight! I tried a glass cutter but either I'm not being heavy-handed enough or the G10 is too slippery, so........

Would anyone like to do the job for me? I could send you the G10 sheet it's only slightly larger than A5 size. Maybe you could cut it to my dimensions and send it back to me? I will, of course cross your palm with silver for your work. Pm me if you can help!

I've buggered it up. I only have hand tools and while the carbon saw blades eat through the G10 easily enough, they bend and I can't seem to saw it straight! I tried a glass cutter but either I'm not being heavy-handed enough or the G10 is too slippery, so........

Would anyone like to do the job for me? I could send you the G10 sheet it's only slightly larger than A5 size. Maybe you could cut it to my dimensions and send it back to me? I will, of course cross your palm with silver for your work. Pm me if you can help!

I can almost hear the disgust in your voice!

I can almost hear the disgust in your voice!