Back in 2003 the wood family visited Frosts knife factory in Mora (pronounced Moora) Sweden, thought some folk might like to see pictures. I am afraid I knew very little about knives at the time so don't ask too many technical questions. I was surprised at the level of mechanisation...robots everywhere, anyway here are the pictures, not the best quality.

Here's the factory.

Blades are cut out of sheets at the suppliers, the laminated blades are made specially apparently a hollow cylinder of low carbon steel has a high carbon bar slotted into it, the whole lot is then heated and rolled to give a laminated sheet. The blades are cut in pairs with tangs facing out in the low carbon sides and blades in the laminated central area.

Rough blades as they arrive at the factory.

I think this machine just polished the sides of the blades.

not sure what these did...

the numbers of blades being processed was staggering and never touched by human hands

This guy in the yellow waterproof ground the bevels on a wet belt sander....one every 20 seconds...no tea breaks or lunch breaks...I bet he was not cheap though.

Racked up ready for hardening and tempering.

They did have a few big grinding wheels but not used much

the vodka machine

and this is where they cook the blades...all pretty high tech

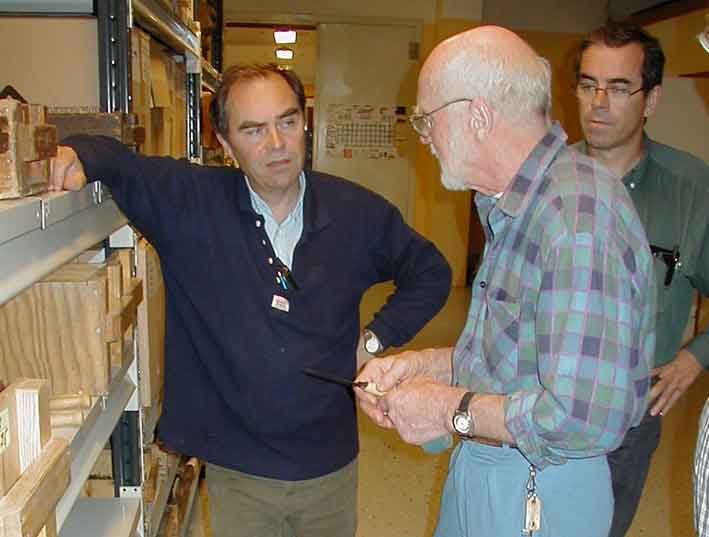

the owners discussing knife design with master carver Wille Sundqvist

and finally a machine that is operated by a human...not sure why a robot can't do this job but it is where the handles are moulded onto the blade...pop blade in 3 secs later take knives out, trim bits off....all day, but its clean and well paid.

2 at a time

they soon pile up

and are sold very cheap in big tubs

The owners said most folk are surprised that they do not move production to the far east but it is part of their philosophy to provide employment locally.

I do like Frosts knives...good design...good materials...serious mass production means unbeatable value to the consumer. In Sweden these knives are used by plumbers, builders, carpet fitters, anywhere you would see a stanley used here.

Here's the factory.

Blades are cut out of sheets at the suppliers, the laminated blades are made specially apparently a hollow cylinder of low carbon steel has a high carbon bar slotted into it, the whole lot is then heated and rolled to give a laminated sheet. The blades are cut in pairs with tangs facing out in the low carbon sides and blades in the laminated central area.

Rough blades as they arrive at the factory.

I think this machine just polished the sides of the blades.

not sure what these did...

the numbers of blades being processed was staggering and never touched by human hands

This guy in the yellow waterproof ground the bevels on a wet belt sander....one every 20 seconds...no tea breaks or lunch breaks...I bet he was not cheap though.

Racked up ready for hardening and tempering.

They did have a few big grinding wheels but not used much

the vodka machine

and this is where they cook the blades...all pretty high tech

the owners discussing knife design with master carver Wille Sundqvist

and finally a machine that is operated by a human...not sure why a robot can't do this job but it is where the handles are moulded onto the blade...pop blade in 3 secs later take knives out, trim bits off....all day, but its clean and well paid.

2 at a time

they soon pile up

and are sold very cheap in big tubs

The owners said most folk are surprised that they do not move production to the far east but it is part of their philosophy to provide employment locally.

I do like Frosts knives...good design...good materials...serious mass production means unbeatable value to the consumer. In Sweden these knives are used by plumbers, builders, carpet fitters, anywhere you would see a stanley used here.