I've made a forge and wonder what's the cheapest way to obtain an Anvil or something that can be used instead of an anvil

Are these any good or is there something that can be recycled/modded??

http://www.machinemart.co.uk/shop/product/details/11-5kg-cast-iron-anvil

that anvil will do for very light work and even then may dent. it will most likely chip if you strike the face with your hammer as it is only cast iron.

there are many alternatives to an anvil.

the do come up quite often on ebay - but be prepared to pay a good bit of coin for them - they go for anything between £50 - 350 (unless you are a jammy git like me and get one for £10.50

)

two good options are - rail road track or a sledge hammer head set in a wood block.

I don't know what you intend on forging but if it is only small stuff like knives then a sledge head will sort you out for some time. indeed I know a few blokes who used them for some years.

A piece of RRT is also a great option - my portable anvil is made from a 12" section of rail which was hardened up using a fire and wheel barrow full of water

- there are a few pics of it up in the Comrie croft picture threads.

only problem with rail track is that if you want to give it a horn it require a LOT of grinding - must have taken me a good few days to get it sorted.

failing those there are other options:

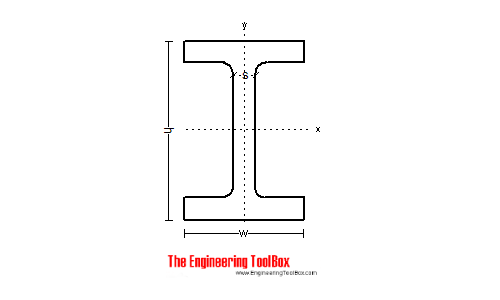

a piece of caterpillar track is quite good. as is a section of fork lift truck steel. - though I do not know if these require hardening - I suspect they do. a good section of I beam works too.

failing all that - a decent chunk of any steel will get you going for the time being.

check ebay - and check your local scrap merchants. if you have a local smith/farrier then go visit them and have a chat - if you are lucky they might have something you can use. I saw the farrier local to me and walked away with a leg vice for a fiver.

all the best

Andy