Hi....i recently saw this on ebay and it was the first 'EA....' serial numbered machine i've seen apart from one that was in totally mint condition and being sold by a sewing machine shop therefore at such a high price i couldnt justify buying it.

the lovely lady, Jan, who was selling it kindly agreed to post it as it was meant to be collection only so here it is. i knew it was going to be hard work and yes i've put a bit of money into it and a helluva lot of time....but hey, she's been worth it.

she's yet to have a 'deep clean'....it was completely filthy and caked with that horrible hardened grime/oil which Sir Mac has since told me was probably caused by someone using incorrect oil on it, most likely 2 in 1....a word of advice....ONLY use top grade and correct oils and greases on your sewing machines!! i use only Singer products...seems sensible huh? and the inside of the machine was as bad as the outside...rank grime, fluff, lumps of it jammed in around the feed dogs...the pivots, rods and levers behind the decorative face plate were the worst i've seen to date...they now look lovely and it runs like a dream. i've been unable to get everything i need as yet...for instance, the metal brackets/plates on the left and right of the base are not correct therefore i cant fit a totally correct extension table....but for now, the first stage is complete. so far its been wiped (vigorously) with only water and then oiled all over...i'll use fairy liquid in warm water and alcohol when i'm ready to put the new decals on. i may also work on the case, sand it, oil.....whatever.

so....here are the initial pictures to give you a starting point...

nothing a toothbrush and a damp cloth couldnt sort out...

it now has new bobbin cover and needle throat plates...these are the original ones (and you cant see on this picture because the part is missing but if you look down at the latest shot from this angle you'll see it has an extra silver wire thread guide....the original had been snapped off....and yes it was a part that was difficult to source, it only arrived today!):

as you can see it was all pretty yucky...

as most of you know i own a lot of these now, currently 15.....and i've noticed that the tension assemblies often differ throughout the years....this one had 'messed up' so i took it all off and re-assembled it according to the instructions in one of my manuals (not all manuals contain this info oddly!) and now its fine and springy as it should be.

the rust came of the spool pin holder with just oil and a hard rub...if only all rust came off that easily!!

i was going to simply put a better condition handcrank on it, mainly because it had a piece missing from the end part that goes into the balance wheel meaning it clanked, metal on metal....but i noticed this one was a bit different and therefore maybe special to the earlier machines....the metal arm is not simply curved, it has a straight bit in the middle....the wood handle is also smaller than most....also its pinned on with brass.....unusual....(i've about ten cranks here and theyre all the same and different from this one)....so i decided to do something about it...

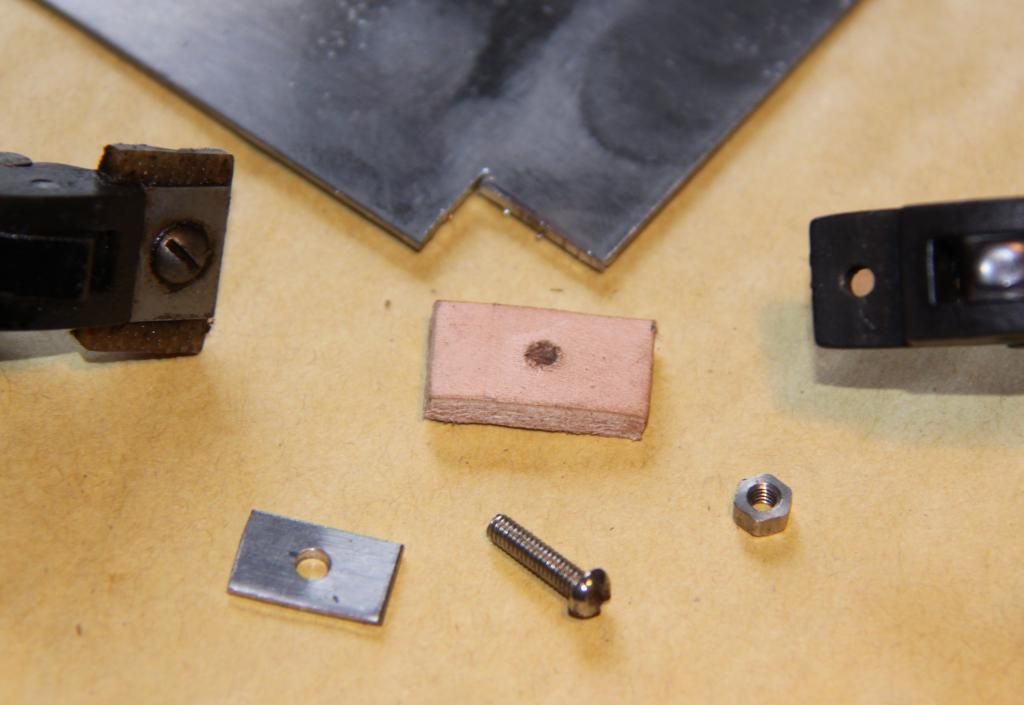

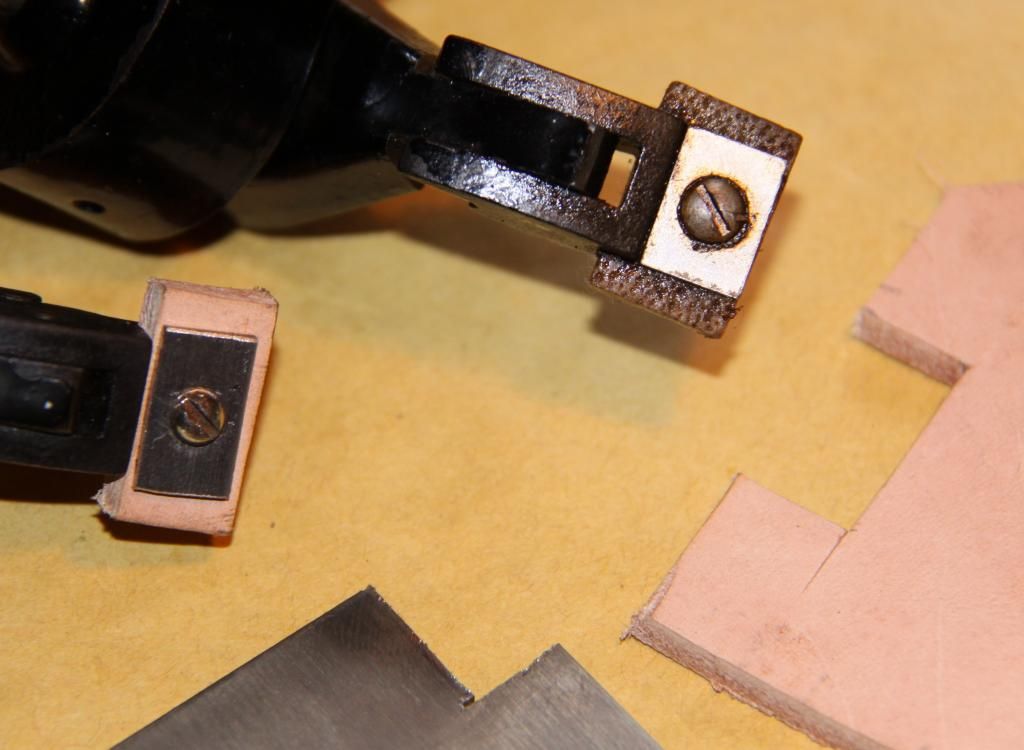

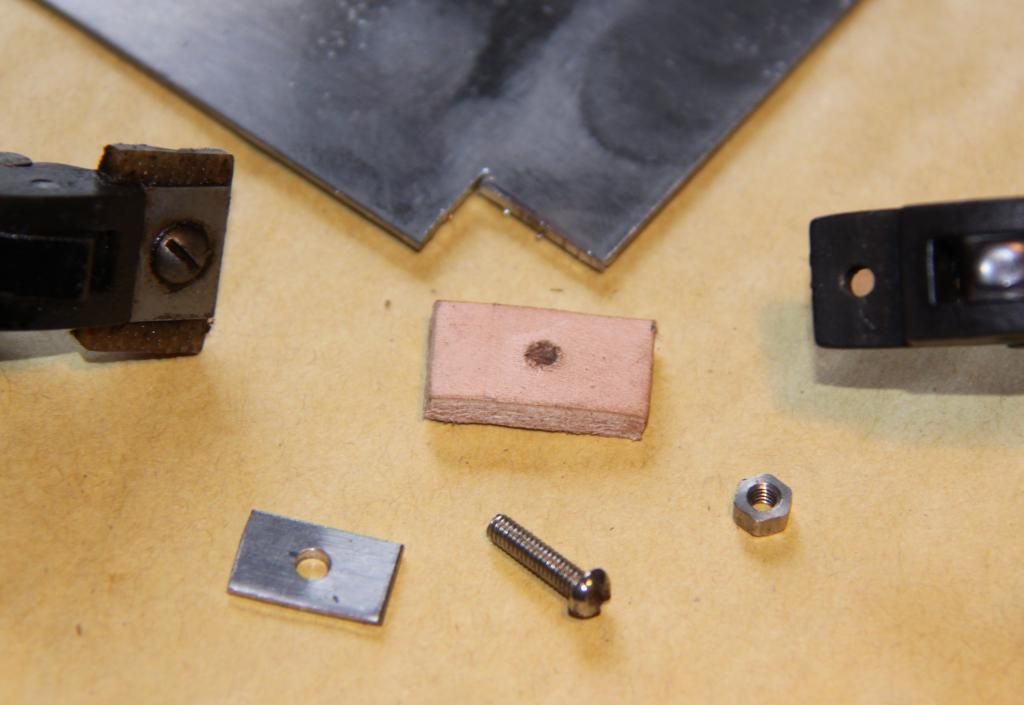

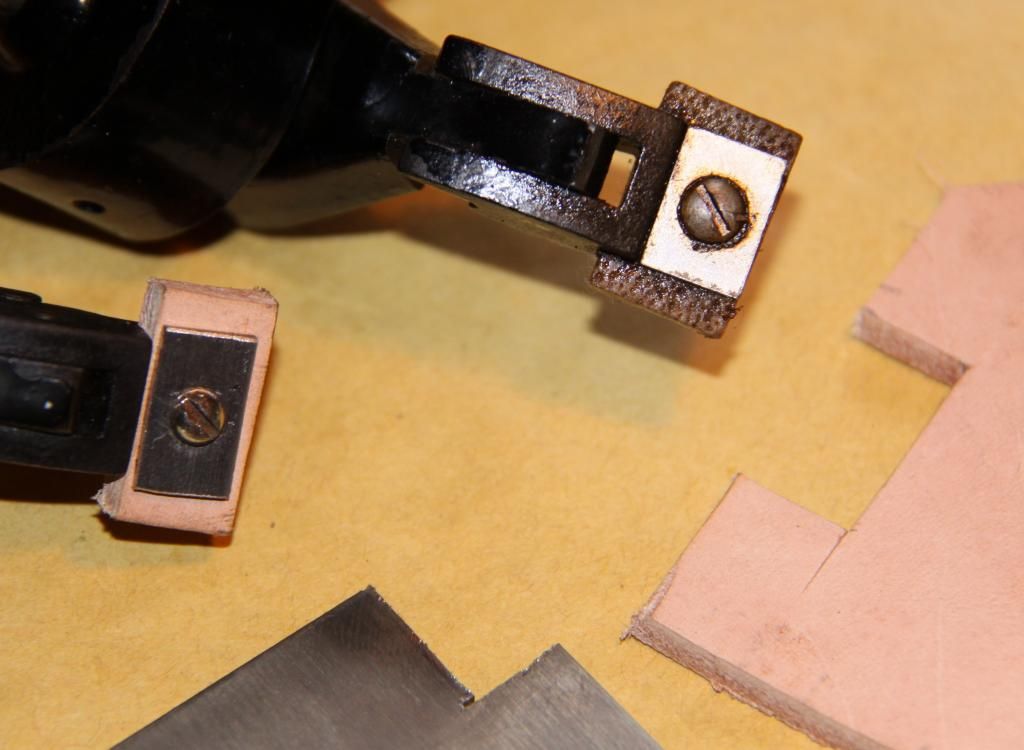

after having a look at how one should be i got meself a sheet of stainless steel and hacksawed out a small piece, drilled a hole in it, nicked an original screw from a different singer part i had, added a bit of leather....not artwork, granted, but i'm rather pleased with meself....i may dye the piece of leather but more likely i'll just add a smidge of oil and let it start to age naturally....

and heres how she looks now....

new lock-brackets where they were missing and shiney new plates...shame about the damaged wood but hey-ho...also you can see the brown staining on the two rods that hold the needle and foot...i'll be stripping all the mechanics out at a later date and cleaning them up properly)....

nice and clean with new red felts present...

fixed handcrank and a new bobbin winder housing...

new balance wheel and oiled handle...

new compartment lid...(of course when i'm saying 'new' i dont mean new as in a modern replica....all parts are original of course)

snazz...........

she now has her own complete 'godzilla' tin of accessories....new key and theres a new lock in the lid too....

and heres the sheet of decals she'll be wearing soon that i got from the U.S.A.....

shes also had various knobs, nuts, thread cutter, etc etc upgraded....there is just one slight problem with her....earlier i mentioned a part that had been snapped off...i'm presuming she took a knock at some point in that area because when trying to get the needle to pick up the thread from the bobbin it doesnt want to...this is because the needle doesnt go straight down but slightly to the right...it mustve been a heavy knock to bend the thick steel shaft (weirdly though it runs smooth as anything, theres no friction at all, its a miniscule amount i'm talking about but enough to cause this problem) that holds the needle but i cant think of any other reason...and the broken thread guide would add to this point...but, alls not lost....i've got the spare parts needed and will be looking at it more closely soon. if i put a bit of pressure on the needle and push to the left and then try it, it picks up the lower thread and she goes on to stitch just fine. all in all i'm pleased and will be soon seeking Sir Macs advice to help me through the decal bit....hope its been of use and interest....dont go throwing these lovely machines in the bin....with a bit of research, effort and t.l.c. these can be restored nearly 100 percent to their former glory! she's 78 years old and looking wonderful....and the best is yet to come!

regards,

sonni

the lovely lady, Jan, who was selling it kindly agreed to post it as it was meant to be collection only so here it is. i knew it was going to be hard work and yes i've put a bit of money into it and a helluva lot of time....but hey, she's been worth it.

she's yet to have a 'deep clean'....it was completely filthy and caked with that horrible hardened grime/oil which Sir Mac has since told me was probably caused by someone using incorrect oil on it, most likely 2 in 1....a word of advice....ONLY use top grade and correct oils and greases on your sewing machines!! i use only Singer products...seems sensible huh? and the inside of the machine was as bad as the outside...rank grime, fluff, lumps of it jammed in around the feed dogs...the pivots, rods and levers behind the decorative face plate were the worst i've seen to date...they now look lovely and it runs like a dream. i've been unable to get everything i need as yet...for instance, the metal brackets/plates on the left and right of the base are not correct therefore i cant fit a totally correct extension table....but for now, the first stage is complete. so far its been wiped (vigorously) with only water and then oiled all over...i'll use fairy liquid in warm water and alcohol when i'm ready to put the new decals on. i may also work on the case, sand it, oil.....whatever.

so....here are the initial pictures to give you a starting point...

nothing a toothbrush and a damp cloth couldnt sort out...

it now has new bobbin cover and needle throat plates...these are the original ones (and you cant see on this picture because the part is missing but if you look down at the latest shot from this angle you'll see it has an extra silver wire thread guide....the original had been snapped off....and yes it was a part that was difficult to source, it only arrived today!):

as you can see it was all pretty yucky...

as most of you know i own a lot of these now, currently 15.....and i've noticed that the tension assemblies often differ throughout the years....this one had 'messed up' so i took it all off and re-assembled it according to the instructions in one of my manuals (not all manuals contain this info oddly!) and now its fine and springy as it should be.

the rust came of the spool pin holder with just oil and a hard rub...if only all rust came off that easily!!

i was going to simply put a better condition handcrank on it, mainly because it had a piece missing from the end part that goes into the balance wheel meaning it clanked, metal on metal....but i noticed this one was a bit different and therefore maybe special to the earlier machines....the metal arm is not simply curved, it has a straight bit in the middle....the wood handle is also smaller than most....also its pinned on with brass.....unusual....(i've about ten cranks here and theyre all the same and different from this one)....so i decided to do something about it...

after having a look at how one should be i got meself a sheet of stainless steel and hacksawed out a small piece, drilled a hole in it, nicked an original screw from a different singer part i had, added a bit of leather....not artwork, granted, but i'm rather pleased with meself....i may dye the piece of leather but more likely i'll just add a smidge of oil and let it start to age naturally....

and heres how she looks now....

new lock-brackets where they were missing and shiney new plates...shame about the damaged wood but hey-ho...also you can see the brown staining on the two rods that hold the needle and foot...i'll be stripping all the mechanics out at a later date and cleaning them up properly)....

nice and clean with new red felts present...

fixed handcrank and a new bobbin winder housing...

new balance wheel and oiled handle...

new compartment lid...(of course when i'm saying 'new' i dont mean new as in a modern replica....all parts are original of course)

snazz...........

she now has her own complete 'godzilla' tin of accessories....new key and theres a new lock in the lid too....

and heres the sheet of decals she'll be wearing soon that i got from the U.S.A.....

shes also had various knobs, nuts, thread cutter, etc etc upgraded....there is just one slight problem with her....earlier i mentioned a part that had been snapped off...i'm presuming she took a knock at some point in that area because when trying to get the needle to pick up the thread from the bobbin it doesnt want to...this is because the needle doesnt go straight down but slightly to the right...it mustve been a heavy knock to bend the thick steel shaft (weirdly though it runs smooth as anything, theres no friction at all, its a miniscule amount i'm talking about but enough to cause this problem) that holds the needle but i cant think of any other reason...and the broken thread guide would add to this point...but, alls not lost....i've got the spare parts needed and will be looking at it more closely soon. if i put a bit of pressure on the needle and push to the left and then try it, it picks up the lower thread and she goes on to stitch just fine. all in all i'm pleased and will be soon seeking Sir Macs advice to help me through the decal bit....hope its been of use and interest....dont go throwing these lovely machines in the bin....with a bit of research, effort and t.l.c. these can be restored nearly 100 percent to their former glory! she's 78 years old and looking wonderful....and the best is yet to come!

regards,

sonni

Last edited: