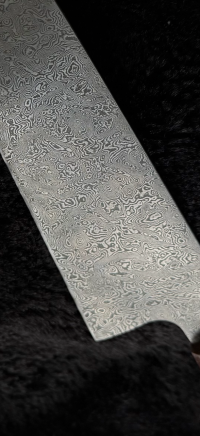

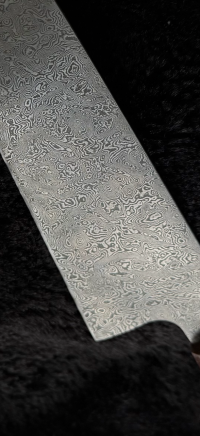

I know these are not really bushcraft related. Apart from the birch burl handles were from a tree I felled seasoned and stablized but here are a couple of Japanese style Santoku chef knives. Both are 192 layers of pattern layered steel of 15n20 and 80crv2

This first knife is a K tip design with a thin spine at 1.6mm at the heel which tapers to 0.9mm at the start of the K tip. With added Mammoth mauler in the handle.

This second blade is seriously thin at 1.2mm at the spine and 0.5mm 1cm away for the tip. With a mahogany bolster.

This first knife is a K tip design with a thin spine at 1.6mm at the heel which tapers to 0.9mm at the start of the K tip. With added Mammoth mauler in the handle.

This second blade is seriously thin at 1.2mm at the spine and 0.5mm 1cm away for the tip. With a mahogany bolster.