Does the thin-ness (blade width not thickness) of the Erickson help alot for carving?

I ask because i want to make a neck knife to go with my convex knife that Stu M is making. But i prefere scandi grinds for carving.

Anyway just wondering what you opinions on how thick to make the knife?

It helps in terms of manoeuvrability. The Eriksson will rotate in a very tight circle (along the long axis through the tang, if you know what I mean), particularly at the tip, but the steel doesnt handle the torque too well it tends to chip-out at the edge quite easily when trying to make a small curved cut with rotational force applied to it (at least in my limited experience). As a result, Im thinking along the same lines as you, in as much that Stu and I made an informal arrangement late last year to do a knife, and he suggested to me that as I liked the Erikssons blade geometry and handle shape so much, that that design should be my starting point for thinking about the project. I though it was an inspired suggestion on his part.

I think the choice of steel and heat treatment would be as every bit as important as cross-section and grind geometry. Its one of the reasons Ive been wanting to try-out a blade in D2 for a while. Im looking for a wood carving knife that will not chip-out too easily and will retain a finely honed edge for an extended time. Ive tried A2, which I like a lot, but Im keen to try something in D2.

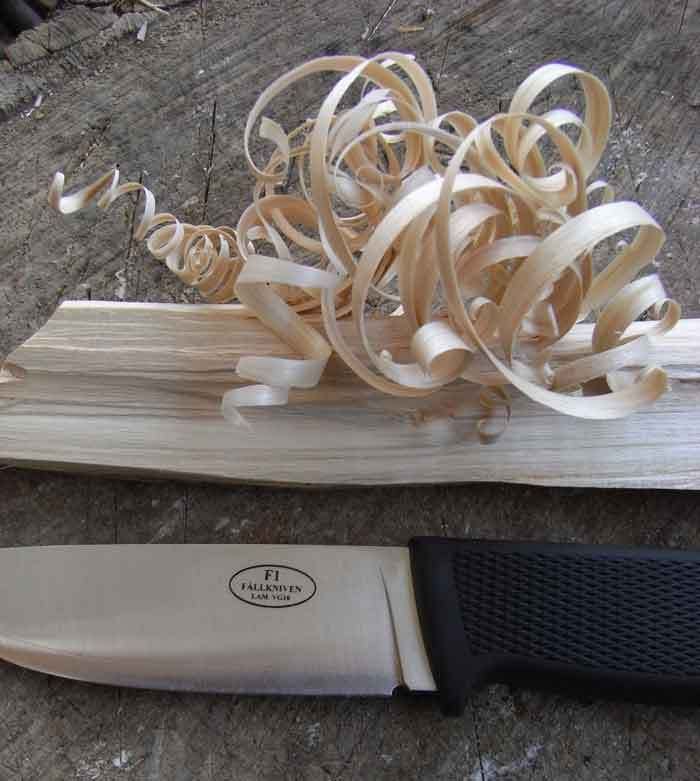

Looks like the knife cut OK - what is the fuss all about?

Stick with the vintner - the only headaches he will give you pass with a new bottle.....

Dont know, and I agree that popping corks is probably better than popping pills

I like what you have done with the plastic, the little diamonds tend to dig in after a while. I have rubbed mine a little with emery, but not anywhere near as much as you have. Is it still grippy?

The handle is still very grippy (even when wet), and a lot more comfortable when using the knife without a glove. Though, as Red has mentioned (a few times, now

) it lacks some comfort when applying a lot of force to the cuts and for prolonged periods. It would help if the skin on the palms of one's hands were like tanned leather, but one of my main contentions about the knife has always been that the F1 may have to be used in extreme sub-zero temperatures, and thus with gloves on (if one wants to avoid frost bite, that is). Im guessing that this [the user would be wearing gloves, and in the case of the F1 the aviator almost certainly would be] and zub-zero temperatures are the whole

reson d'etre for the Thermorun range of knives. Of course, the Kraton handle of the H1 might also be of value in any climate, if you find yourself up to the elbows in caribou gore etc.

I trimmed the checkering off with a pocket knife, but Im still looking for the right technique to smooth the Thermorun with abrasives to produce a scratch-free finish, and I could have been a bit neater when trimming it with the knife too.

Cheers,

Paul.

...I had feared for the worst

...I had feared for the worst

I can only dream of mellow, John, but you've given me a goal to aim for in the new year. I expect mellow would be a welcome change to my more usual '**** and vinegar'

I can only dream of mellow, John, but you've given me a goal to aim for in the new year. I expect mellow would be a welcome change to my more usual '**** and vinegar'