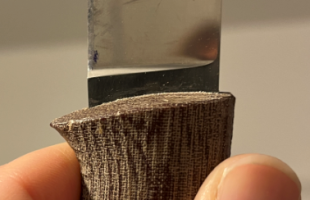

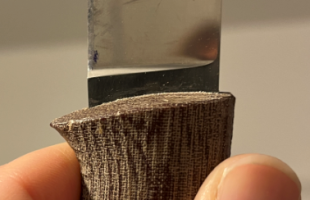

"....regarding the weak spots do you mean this area where my thumb nail is?"

Yes, that is the spot. Sharp lines look great, but if the knife is dropped you can lose a chip. Maybe it isn't a common problem, but it has happened to me on a couple, one was a particularly nice handle that I would rather it not have happened on. Showing it to the neighbour and he dropped it butt first on the stone path. I have done varying degrees of rounding on different knives. Easiest to show what I mean with a sketch. Doming makes for a stronger corner, doming and rounding the corners themselves makes it even stronger, and obviously a little gentler on hands.

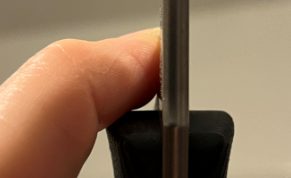

Handle front, the two factors. The bevel for cleaning looks like this, harder to do when the front edge is curved, as on your design

Much easier when straight.

Doesn't need much, you can test with some scrap on a flat surface, just want enough opening of the angle so you can run a finger/cloth around and easily reach the bottom of the corner.

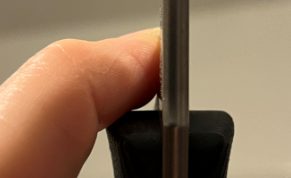

For comparison, a Lion Steel with 90deg scales.

I don't make many hunting knives, but my "bushcraft" knives mostly have a slight widening at the front that helps with pinch grip. If I was aiming for hunting, I would aim to have a little flat or something to help locate the pinching thumb. I would look at Loveless style hunters to see what I mean about flatter sides at the handle front.

Neat trick for keeping glue off blade, sometimes works really well, brown packing tape, stuck to blade, dry fit scale, scalpel cut tape to trace front of scale, remove scale, peal off tape from where scale fits. Glue down, blade is masked, can wipe glue away from join and not worry about getting it on the steel. Pealing off tape while glue is just a little soft still (mine takes over 24 hours to fully cure, so next morning is fine for me). Much less scraping to do with brass chisel.

All the best and good luck!

Chris