Might be an idea to do a disc bolster and a wrap - the wrap should prevent it splitting (a bit of epoxy in the cracks to help waterproof to prevent rotting...) and the Bolster should take a bit of the strain so it's not all going on the wood handle...

Being a 'belt and braces' type that appeals to me.

...That being said, at this point I'd probably make the new handle and then add the wrap and bolster to that...

This appeals to me also

Interlocking grain should be the most resistant to stress. The annual rings in some woods tend to grow in opposite direction each year and produce a wood which can be a real PITA to work...

As I understand it, it depends on what kind of stress the wood is put under, In some circumstances it seems stronger, and under others, weaker.

The growth rings can reverse direction each year, or every few years, depending on the the species or the genetics of an individual tree. It seems like a complex subject, and gets more complex the further one delves into it. Plant biology is not my strong point (not that I have a strong point

).

...It does not really make them any stronger, just more difficult to work!...

I think if you are a wood turner the 'fluffy' grain that results from some types of interlocked grain can be troublesome when it comes to a silky finish to the wood.

...The wood section on the handle seems to be fairly thin and because of the stresses imposed on it by a (I assume) fairly big blade will make most woods crack in the same place. You could wrap either some strong thread or brass wire or hand sew some rawhide around the handle. You could get some rawhide from a pet shop, one of these rawhide bone, well soaked and tightly sewed around the handle should prevent more splitting.

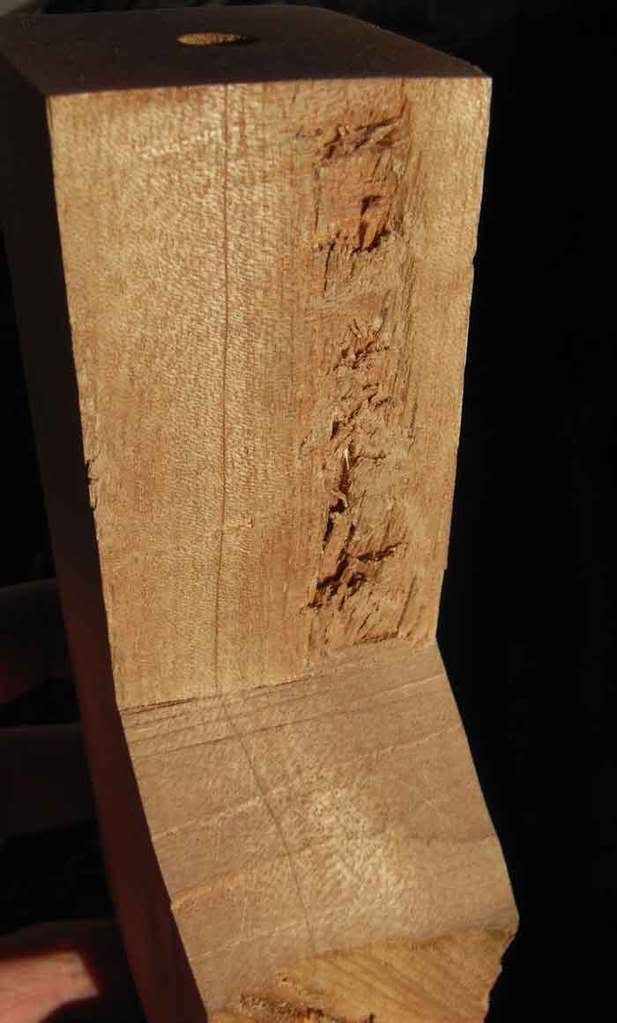

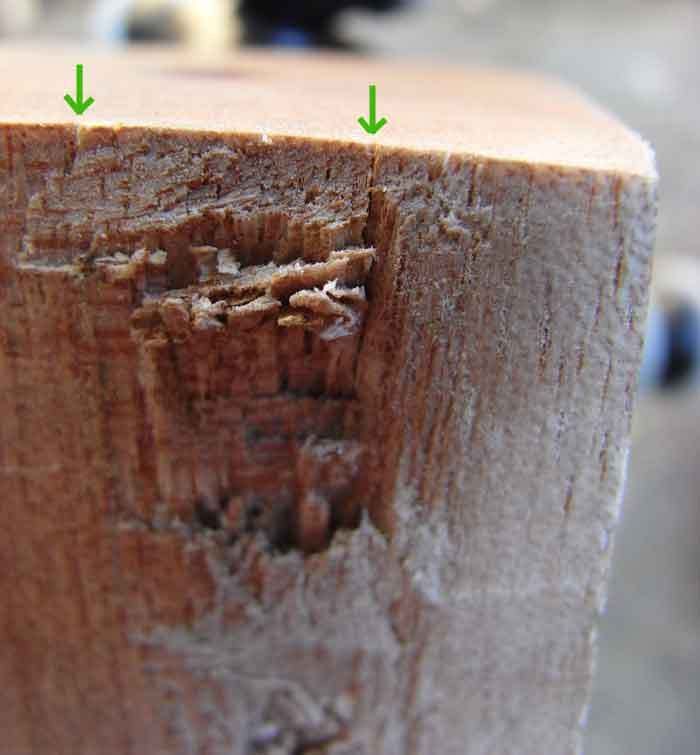

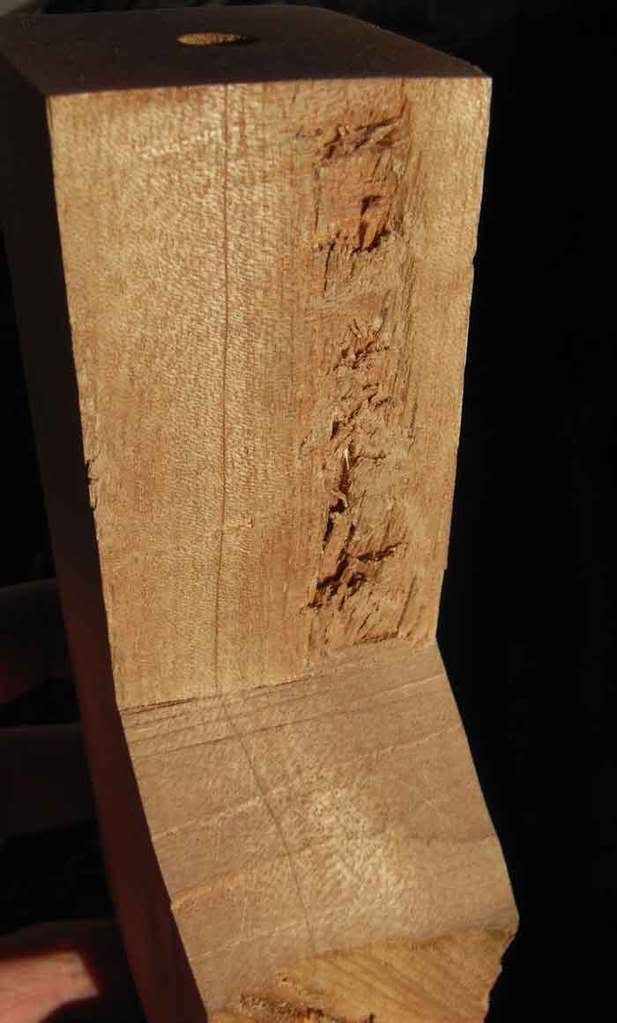

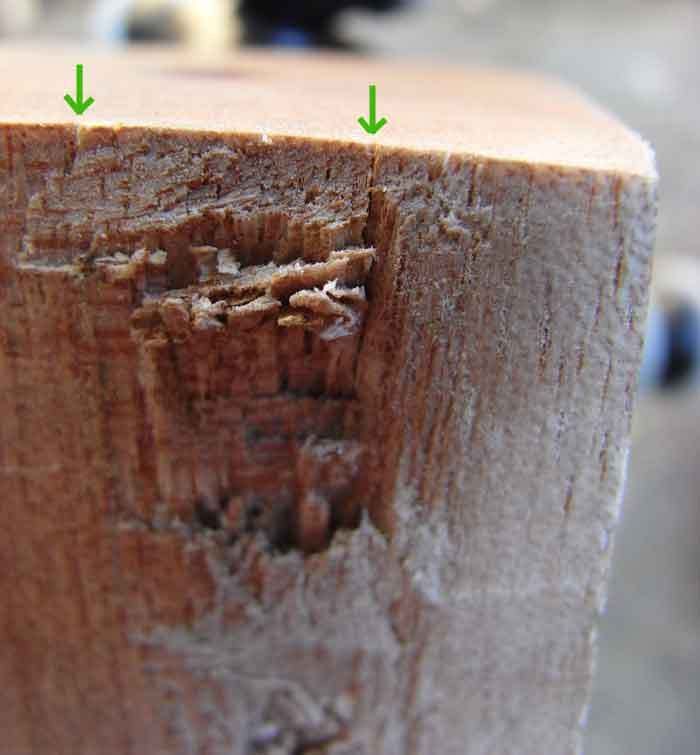

Yep, the lower edge of the tang mortise is very close to the edge of the handle, I dare say many types of wood would have split under the stresses of heavy chopping, without reinforcement, such as the rattan on BOD's large Parang.

Looking at the grain, I think it is a similar type of wood to the handle on [my] parang which...has a thin rattan plait, like a turks head, around it.

Not used much on the trail, this parang has been doing considerable axe-type work chopping down trees, including palm trees, and splitting wood for fire since about 2003 with no sign of failure yet, touch wood...

Interesting, BOD, thank you.

...Don't know nothing about interlocking grains etc.but a bolster is a good idea if you do not want to spend time making a new handle further down the road

...

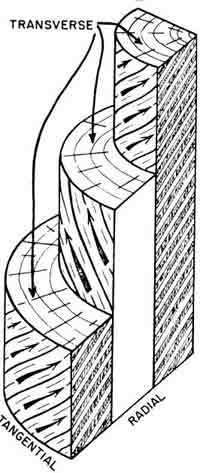

I could well be going with a bolster, and this illustrates the basics of interlocked grain on a tree trunk, though it does get a bit more complicated with woods that are from pollarded, burl/burr, or root woods:

...My guess is that these designs do not have additional reinforcements as they assume that the skills to fashion a new handle are widespread in the community...

I'm trying to do my bit to spread those skill further afield

...You are doing well by keeping these skills alive

...

That's excellent news, BOD, thank you

A thick steel or brass ferrule is the best to prevent splitting. The ferrule should be a tight fit to compress the wood. If you can't get a ferrule, you can try some wet sinew wrapped tightly and left to dry.

A ferrule was one of my first thoughts, but the non-circular cross-section of the handle has made me reconsider:

What sort of wud is your blank?...

That's what I've been tryng to find out -

http://www.bushcraftuk.com/forum/showthread.php?t=28214

...Some split more easier than othe's do, it depends what purpose as to get the best species for the job in hand. EG as has been said elm doesnt like to split which is why they always used it for hub's on cart wheel's, they wouldnt break up with all the mortice's in them for the spoke's. Chestnut on the other hand just loves to split, it splits itself almost, so its real nice to use if you want lots of thin rail's quickly. Wild/burr grain to my mind is sometimes a bit more durable than nice neat straight grain wood, but as Jojo said is tricky to work; but nothing that cant be sorted with sharp knife's, files, rasp's, scraper's etc. That piece you have in the picture's could well be OK it just need's care to get a decent finish with the wild grain showing up. A ferrule seems the likelist solution to reinforce the joint of blade to handle, its traditional because its proven to work (eg on mortice chisle's, bill hook's) and its easy to fit up. I'd be looking for a clean section of branch 4 to 5 inch diameter with a natural knee bend in it; split it in half, get the pithy centres out, then hew and refine your handle form from the best half plus you have a spare in case you mes up. The knee bend is a natural form of lamination, they used them in ship's and timber frame buildings for there strength as corner braces. If you carved your form from straight stock, the swell end will have short grain which is also a weak point where it may well snap under real stress. I'd go for ash, or elm (you can often get small section elm, surprisingly) or also possibly hawthorn. You can get steel tube for ferrul'es from any steel stock holder, they will generally cut it for you nice and square on there band saw. Make sure your handle is well bone dry before you fit the ferrule on or else it will loosen if the wood was wet and shrinked more.

Hope this help's, cheers Jonathan

Excellent stuff, Jonathan, much to think about, thank you!

If you want a quick and dirty fix supaglue is great. Squirt it into the cracks then clamp it in a vice to keep the cracks tight as the glue goes off. Then bind it up tight with strong linen thread like the ones in BODs pictures, squirt the thread with supaglue too if you like. I would expect a handle with a fix like that to take many years hard use and it would take 10 minutes to do.

'Quick and dirty' is my thing, but I'm trying to mend my ways, Robin

Seriously, I'm into skills and wood in an ever increasing way. I mean, this is a wood chip thrown by an axe earlier in the day. Who could not be beguiled by this material (an example of interlocked grain at the junction of tree branches):

Thanks to all for your interest, very much obliged to you,

Paul.

Seriously, I'm into skills and wood in an ever increasing way. I mean, this is a wood chip thrown by an axe earlier in the day. Who could not be beguiled by this material (an example of interlocked grain at the junction of tree branches):

Seriously, I'm into skills and wood in an ever increasing way. I mean, this is a wood chip thrown by an axe earlier in the day. Who could not be beguiled by this material (an example of interlocked grain at the junction of tree branches):