How do I go about sharpening my spoon knife, its an Erik frosts mora with two cutting edges both on the outside edge of the curve.

How do I sharpen a spoon knife?

- Thread starter Barney

- Start date

-

Come along to the amazing Summer Moot (21st July - 2nd August), a festival of bushcrafting and camping in a beautiful woodland PLEASE CLICK HERE for more information.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Try wrapping some fine wet and dry on a piece of wooden dowel, then shapening the inside of the hook. If you have a slipstone that will work just as well and is what I use.

On that particular knife, the bevel(s) is(are) on the outside. The inside should only be stropped.

I would start with 80 or 150 grit wet/dry sandpaper on the outside and blend the large secondary bevel with the curvature of the blade. In other words, make everything smooth. A block of wood with a piece of hard rubber glued to it and then covered with sand paper will make things go quickly. Make sure you use hard rubber, not a mouse pad. This will allow you some resilience but allow the sandpaper to dig in and do it's work.

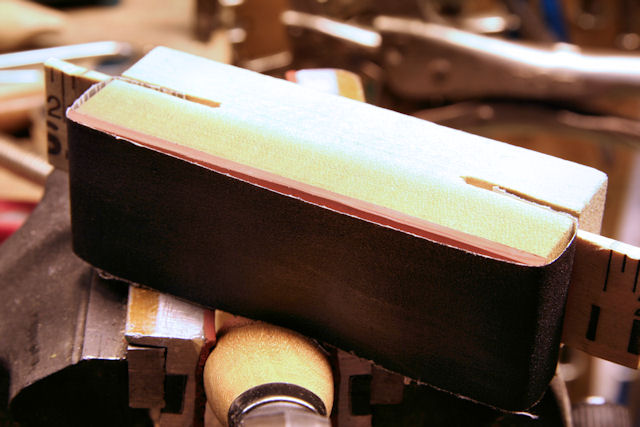

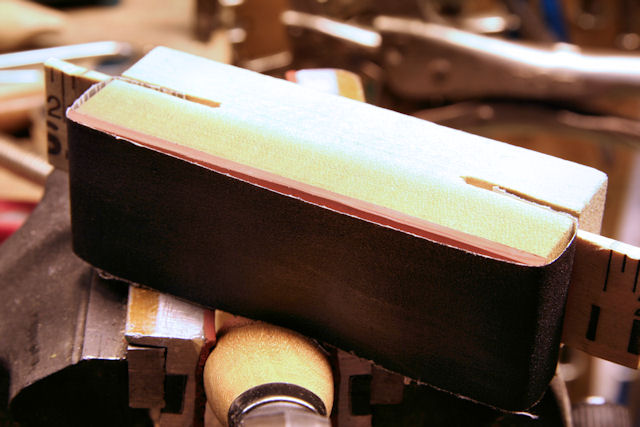

Here is a photo of the sanding block I use. Clamp the knife in a vise and sand parallel to the edge until the bevel is gone. When you get to finer grits, you may want to clamp the hone in the vise and hold the knife in your hand to sharpen. But for reprofiling, I find it easier in the beginning to clamp the knife.

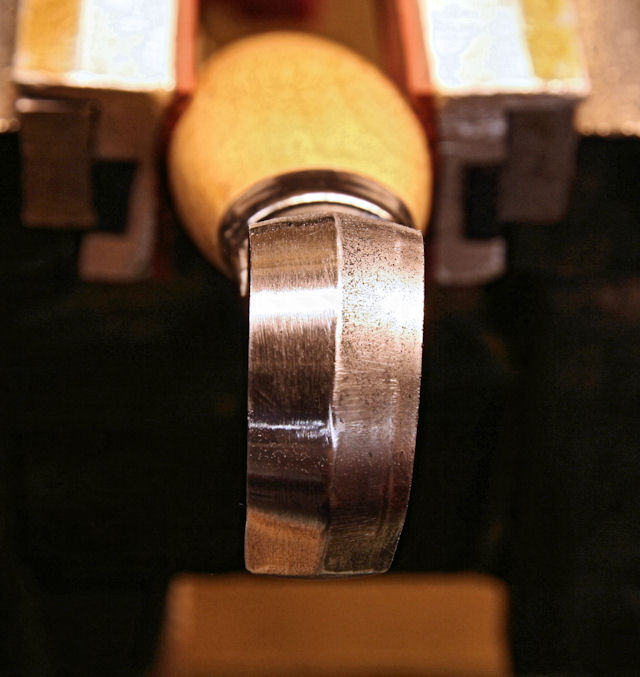

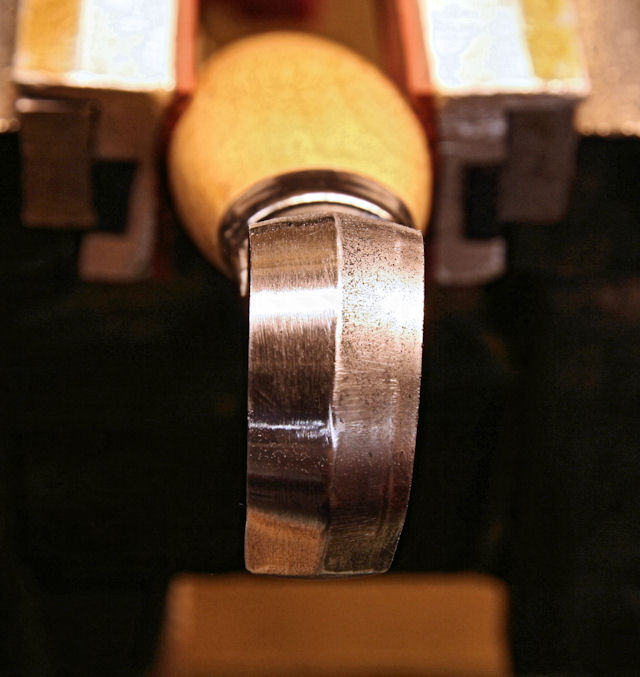

Here is a pic of one side with the bevel sanded nearly smooth with 150 grit and the other side with the bevel still intact. It takes less than 5 minutes to do this.

Repeat with 220 grit paper, then switch to a block that has a piece of mouse pad glued to it and begin smoothing the bevels with 400 grit paper, going out to 2000 grit, if you have it. Then strop on a piece of leather backed by a mousepad (made the same as the hone shown above), and strop the inside with a leather-covered dowel rod. For stropping, white gold stropping compound works incredibly well.

At some point, if you want, you can stop sanding parallel to the edge and sand with the edge trailing. Either method, though, will get you there.

I would start with 80 or 150 grit wet/dry sandpaper on the outside and blend the large secondary bevel with the curvature of the blade. In other words, make everything smooth. A block of wood with a piece of hard rubber glued to it and then covered with sand paper will make things go quickly. Make sure you use hard rubber, not a mouse pad. This will allow you some resilience but allow the sandpaper to dig in and do it's work.

Here is a photo of the sanding block I use. Clamp the knife in a vise and sand parallel to the edge until the bevel is gone. When you get to finer grits, you may want to clamp the hone in the vise and hold the knife in your hand to sharpen. But for reprofiling, I find it easier in the beginning to clamp the knife.

Here is a pic of one side with the bevel sanded nearly smooth with 150 grit and the other side with the bevel still intact. It takes less than 5 minutes to do this.

Repeat with 220 grit paper, then switch to a block that has a piece of mouse pad glued to it and begin smoothing the bevels with 400 grit paper, going out to 2000 grit, if you have it. Then strop on a piece of leather backed by a mousepad (made the same as the hone shown above), and strop the inside with a leather-covered dowel rod. For stropping, white gold stropping compound works incredibly well.

At some point, if you want, you can stop sanding parallel to the edge and sand with the edge trailing. Either method, though, will get you there.

Cheers Hoodoo.

I thought it a bit odd having a secondary I will get shut of it as you suggest.

Thanks for advice.

I thought it a bit odd having a secondary I will get shut of it as you suggest.

Thanks for advice.

Hoodoo cheers mate

I have only got out to 800 grit and it does not feel sharp yet .

.

But by gum what a difference to the cutting performance and efficiency the modification that you recommended made. The finish and cutting control is better in both hard dry wood and green wood.

Why does the knife not come with that grind when purchased?

Thanks again, I cannot believe the improvement.

I have only got out to 800 grit and it does not feel sharp yet

But by gum what a difference to the cutting performance and efficiency the modification that you recommended made. The finish and cutting control is better in both hard dry wood and green wood.

Why does the knife not come with that grind when purchased?

Thanks again, I cannot believe the improvement.

Hoodoo cheers mate

I have only got out to 800 grit and it does not feel sharp yet.

But by gum what a difference to the cutting performance and efficiency the modification that you recommended made. The finish and cutting control is better in both hard dry wood and green wood.

Why does the knife not come with that grind when purchased?

Thanks again, I cannot believe the improvement.

Glad I could help. If you find yourself with a very heavy burr on the inside, you can take some 1000 grit wrapped around a round dowel and run it on the inside very lightly, keeping it as flat as possible, to remove the bur.

Keep in mind that if you use the knife before stropping the burr off, the edge will go dull very very quickly.

800 grit is not a bad finish for a carving knife. You just have to do a lot of stropping.

Yes, I've always wondered that myself. The Frosts sloyd carving knives are just so superb and have the prefect profile and grind for whittling - why don't these work just out of the packet too? Maybe we ought to start hassling Frosts about it!Why does the knife not come with that grind when purchased?

Nicola

Excellent shots Hoodoo.

I have always maintained that it takes a load of work to make a Frost hook even generally useful, and such an out-of-the-box project is not a beginners task.

By the time you invest so much in it you could have easily bought a quality hook from a custom maker.

This tutorial should certainly help loads of folks sitting on a Frosts wondering why it carves so poorly.

I have always maintained that it takes a load of work to make a Frost hook even generally useful, and such an out-of-the-box project is not a beginners task.

By the time you invest so much in it you could have easily bought a quality hook from a custom maker.

This tutorial should certainly help loads of folks sitting on a Frosts wondering why it carves so poorly.

Great post Hoodo

Can I just ask where you get the hard rubber from and do you sand from blade to spine or the other way around?

Cheers

Heath

Can I just ask where you get the hard rubber from and do you sand from blade to spine or the other way around?

Cheers

Heath

I'm concerned about use of the mouse mat. My experience is that for carving you want a completely flat bevel so you can carve with accuracy. (That's why the secondary on these knives are such a pain.) Surely the mouse mat is a soft surface that will give you a slightly convex surface?

I sharpen using abrasives fixed directly onto a piece of planed softwood or MDF then finish with Autosol paste on the same. That way you're always using a hard, flat surface and come out with a completely flat bevel (if you have a good eye).

Nicola

I sharpen using abrasives fixed directly onto a piece of planed softwood or MDF then finish with Autosol paste on the same. That way you're always using a hard, flat surface and come out with a completely flat bevel (if you have a good eye).

Nicola

Excellent shots Hoodoo.

I have always maintained that it takes a load of work to make a Frost hook even generally useful, and such an out-of-the-box project is not a beginners task.

By the time you invest so much in it you could have easily bought a quality hook from a custom maker.

This tutorial should certainly help loads of folks sitting on a Frosts wondering why it carves so poorly.

My double sided frost spoon knife cost £10, I used it for a year, and other than the pain it was to sharpen I learnt enough from using it to know what I wanted when I bought a custom (a left handed one from Dave Budd) I think that the double sided one is a great learning tool to start with, and comes sharp enough from the box to make spoon from the get-go. I made dozens of spoons and even a large cup from well seasoned cherry.

As for time and effort in sorting it out Dave Budd did a bang on job reprofiling mine and only charged about £7 (including postage).

So for an outlay of £17 (half what a handmade custom spoon knife cost), Ive a double sided one that works as good as my custom.

If it is a choice of saving up and buying a custom spoon knife or spending a £10 on a frosts. Id say you are better of spending the £10. That way you will learn enough to actually know what kind of hand made custom knife you want

I'm concerned about use of the mouse mat. My experience is that for carving you want a completely flat bevel so you can carve with accuracy. (That's why the secondary on these knives are such a pain.) Surely the mouse mat is a soft surface that will give you a slightly convex surface?

I sharpen using abrasives fixed directly onto a piece of planed softwood or MDF then finish with Autosol paste on the same. That way you're always using a hard, flat surface and come out with a completely flat bevel (if you have a good eye).

Nicola

Hmmmm....I'm concerned about your concern.

Let's take a look at this eh?

First, I might agree with you on a regular straight bladed knife (with some reservations...) but we are talking about a knife that is round. You will never be able to cut flat planes with a round knife, even if the bevel is straight. The smallest arc on a round knife would still be curved. At least, that's what I learned in geometry class.

Second, there are very vew flat sufaces I would want to carve on a spoon with a spoon knife. If I want SMOOTH (not flat) I personally use a scraper. For bushcraft though, it's totally irrelevant imo.

Third, maybe we can ask the question, does the flat beveled spoon knife carve better? Does it make carving easier? Well, I'd have to respond in the negative. In fact, given all the spoon knives I own, the ones with convex grinds are the most effective in my experience. But if you won't take my word for it, you might want to contact that British spoon carving bloke Robin Wood. I have see him state on this forum that one of his favorite spoon knives is made by Del Stubbs. Now Del's knives come with a full convex grind. My personal experience with them has been pretty fantastic but still, I would check with that Robin guy.

Also please note, when you switch to the mousepad at the higher grinds, your are not really shaping the bevel so much as polishing it. My Frosts are not nearly as convexed as my Stubbs knives.

YMMV.

I've been married to him for the last eighteen years hoodoo!But if you won't take my word for it, you might want to contact that British spoon carving bloke Robin Wood. I have see him state on this forum that one of his favorite spoon knives is made by Del Stubbs. Now Del's knives come with a full convex grind. My personal experience with them has been pretty fantastic but still, I would check with that Robin guy.

I'm not sure what grind Del puts on his curved spoon knives, I've never really got on with them, and both Robin & I favour some scandinavian ones shape-wise. It's Del's straight sloyd knives we rave about. Now these actually have a bit of a concave (hollow) rather than a convex grind.

I don't quite follow your logic on the convex edge, but this is one of those conversations that would be so much easier if we could sit with a piece of paper and draw what we mean! I want a curve blade that only bends in one direction, from the handle to the tip. If the bevel also curves from the sharp edge to the back of the blade I think you have less control over the blade in the same way as for a straight knife. Maybe because you're always hollowing it is less critical, but still I think it is better flat.

At the end of the day, I carve a hell of a lot of spoons and get on well with the way I sharpen my knives so it works for me. If it's the same for you we should agree to differ!!

Nicola (Wood) aka Dr Spoon

robin wood

Bushcrafter (boy, I've got a lot to say!)

That one picture is worth a lot of words, well done Hoodoo.

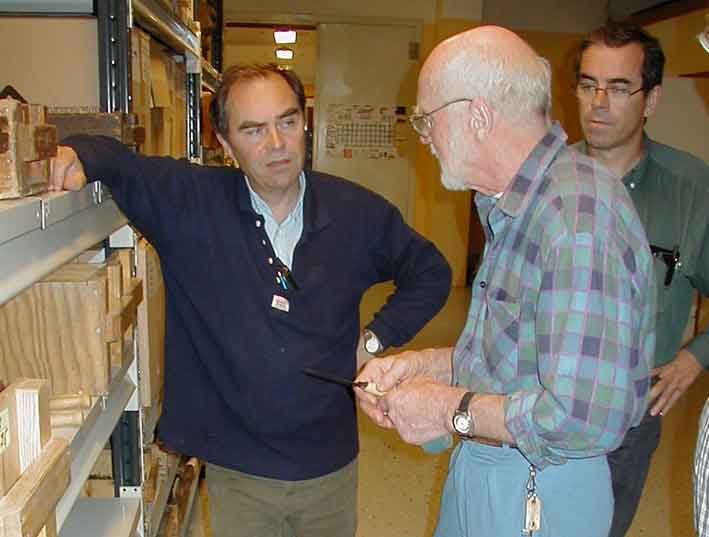

It frustrating that these tools don't come ready to go out of the box, the straight sloyd knives are so good and such good value. We visited the Frosts factory with Wille Sundqvist 6 years ago, here he is with the owners and we did have a long discussion about these knives.

As I saw it the bottom line was that whilst we may think they do a lot of them it is a very tiny production run compared to most of their knives and they sell so there was not much incentive to rework them.

I think with the modification shown in Hodoos picture the frost will work OK. What makes a hook really sweet and how to achieve it is very difficult to say. I have been forging my own woodturning hooks for nearly 20 years and they effectively do the same job and have a similar though slightly beefier sections. We also have examples of most of the spoon hooks by most makers. Whenever I think I have worked out exactly why the good ones work and the so so ones don't quite hit the spot I find another that breaks the theory.

Our favourite hook knives are made by two Swedish smiths Hans Karlsson (though I have modded ours a little) and Bo Helgesson (these were wonderful out of the box though he has not made any for sale for a few years) Both these knives have relatively short concave bevels which allows you to easily hone them flat. A very wide flat bevel will chatter as it tries to ride over a concave surface. I have some knives I have forged myself, particularly one I use many times a day to finish the inside of my turned bowls which is completely convex and works well.

The perfect sweet cutting hook is a joy but it is not an easy thing to create.

In the meantime, this mod to the frosts will be a good help to many I am sure.

I've been married to him for the last eighteen years hoodoo!

Do tell!

Sorry Nicola, I was just having a little fun.

Ultimately, if it works it works, and the main thing is to enjoy carving. I do agree with Robin's comment about the chatter you can get from a wide flat bevel, which is why I think a shallow convex works so well when the goal is to carve a curve. But I'm also a big fan of Han's spoon knives and the tight curvers you can make with them.

At any rate, cheers!

Similar threads

- Replies

- 10

- Views

- 876