Hello folks, I think this is my first post on this forum so I hope it's in the right place!

I thought Id just share a little project Im up to at the moment. I got a wonderful Fieldcrafter blank for Christmas from the wife which Im even more glad to have got my hands on one now that Matt has stopped making them. It really is a wonderful blade! Anyway, Im sure youre all aware of the quality of these knives so I wont ramble on too much about them, but if you havent got one and ever get the chance to own one, do it! You wont be disappointed.

My next problem was how to choose what to make the handle scales out of, so many choices! Micarta always looks good in a utilitarian kind of way, the Corian stone effect ones the Matt was offering were very nice indeed too! (I nearly bought a white one in his end of shop mad sale!) But as my knife is hopefully going to be something that I can pass on to my son in some very distant year I thought Id go for a classic look. For this I chose English Walnut, classy and classic I hope itll be a fitting finish to this fantastic blade. This also means when I get some nice walnut furniture for my rifle they will be a matching pair.

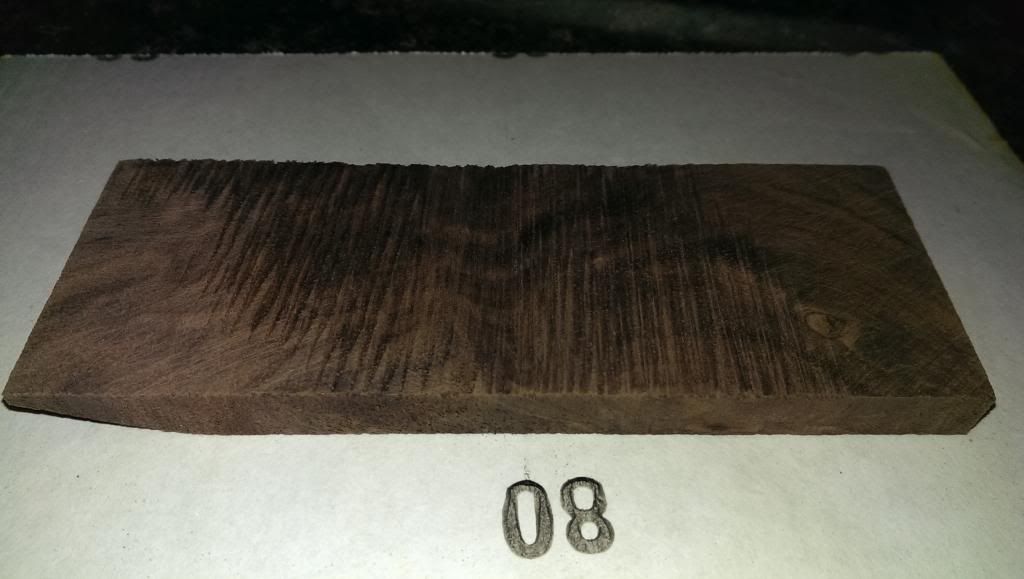

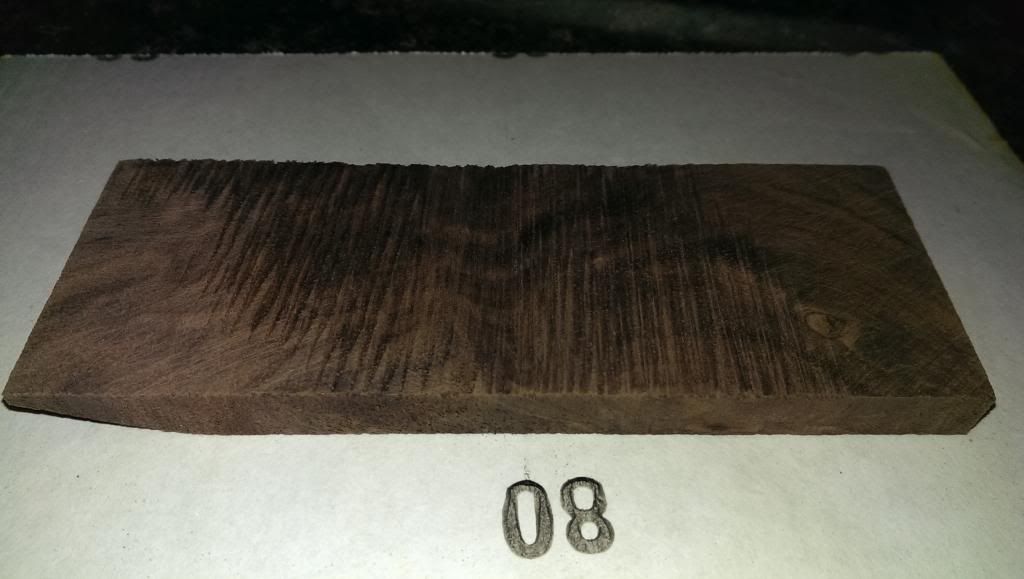

I found some nice looking pieces of wood from an eBay seller for a reasonable price and a few days later they landed through my door. Happily they look as nice in real life as on the advert so I pleased.

Not so happily they were very rough cut and had deep gouging all over, one was also slightly warped. Oh well, no bother, nothing that some elbow grease wouldnt sort out! So tonight Ive made a start. First job was to prep the sides that will be bonded to the tang as they were far from ready. So I sat down in from of an episode of Ray Mears (seemed appropriate!) with some sand paper and a flat surface and set to it. The warped one took almost a whole episode of Ray passing on his knowledge to get flat but it ended up how I wanted it.

Notice opposite corners have been sanded but the middle remains rough.

The scratches in the center were very persistent!

But eventually it was made flat!

This pic shows how much bend there was. Right hand edge is original, left is sanded.

The second block took nowhere near as long and before long I could sketch out where Id like to cut the scales from, making the most of the pattern and avoiding as many problematic bits of the wood as possible.

Well, thats enough for tonight, Ill keep you posted as things progress. Thanks for reading, if anyone has any tips Id be more than happy to receive them. Ive done my research but this is the first time Ive made knife scales, heres hoping they turn out ok! Later this year I hope to try the whole process and make some blades from some files I have saved for the purpose.

Jim

I thought Id just share a little project Im up to at the moment. I got a wonderful Fieldcrafter blank for Christmas from the wife which Im even more glad to have got my hands on one now that Matt has stopped making them. It really is a wonderful blade! Anyway, Im sure youre all aware of the quality of these knives so I wont ramble on too much about them, but if you havent got one and ever get the chance to own one, do it! You wont be disappointed.

My next problem was how to choose what to make the handle scales out of, so many choices! Micarta always looks good in a utilitarian kind of way, the Corian stone effect ones the Matt was offering were very nice indeed too! (I nearly bought a white one in his end of shop mad sale!) But as my knife is hopefully going to be something that I can pass on to my son in some very distant year I thought Id go for a classic look. For this I chose English Walnut, classy and classic I hope itll be a fitting finish to this fantastic blade. This also means when I get some nice walnut furniture for my rifle they will be a matching pair.

I found some nice looking pieces of wood from an eBay seller for a reasonable price and a few days later they landed through my door. Happily they look as nice in real life as on the advert so I pleased.

Not so happily they were very rough cut and had deep gouging all over, one was also slightly warped. Oh well, no bother, nothing that some elbow grease wouldnt sort out! So tonight Ive made a start. First job was to prep the sides that will be bonded to the tang as they were far from ready. So I sat down in from of an episode of Ray Mears (seemed appropriate!) with some sand paper and a flat surface and set to it. The warped one took almost a whole episode of Ray passing on his knowledge to get flat but it ended up how I wanted it.

Notice opposite corners have been sanded but the middle remains rough.

The scratches in the center were very persistent!

But eventually it was made flat!

This pic shows how much bend there was. Right hand edge is original, left is sanded.

The second block took nowhere near as long and before long I could sketch out where Id like to cut the scales from, making the most of the pattern and avoiding as many problematic bits of the wood as possible.

Well, thats enough for tonight, Ill keep you posted as things progress. Thanks for reading, if anyone has any tips Id be more than happy to receive them. Ive done my research but this is the first time Ive made knife scales, heres hoping they turn out ok! Later this year I hope to try the whole process and make some blades from some files I have saved for the purpose.

Jim