I have done a few bags now and sometimes shown the progress, but I dont recall going through one step by step.

Lets start with the basics required for a small shoulder bag. This one is going to be loosely based on the Mk4 Gasmask / Indiana Jones bag.

Sewing machine is a must, I started with my wifes bog standard domestic machine. It could quite happily cope with a few layers of 1000d material, so would be fine for this project.

Needles and thread. I use denim/jeans needles and Coat Nylbond 60 thread. This works well for me and I would think it is a good starting place for anyone starting. Dunelm Mills stock both and are one of the cheapest places for the thread, although a little limited on colours.

Material. I usually use 1000d or 600d material, although have also used Goretex as well. I sometimes line with a different material, but for ease you can use the same on the inside and outside of the bag.

Unless the bag is for something really special (when I will use genuine 1000d Corudra) I tend to use 600d material from Ebay.

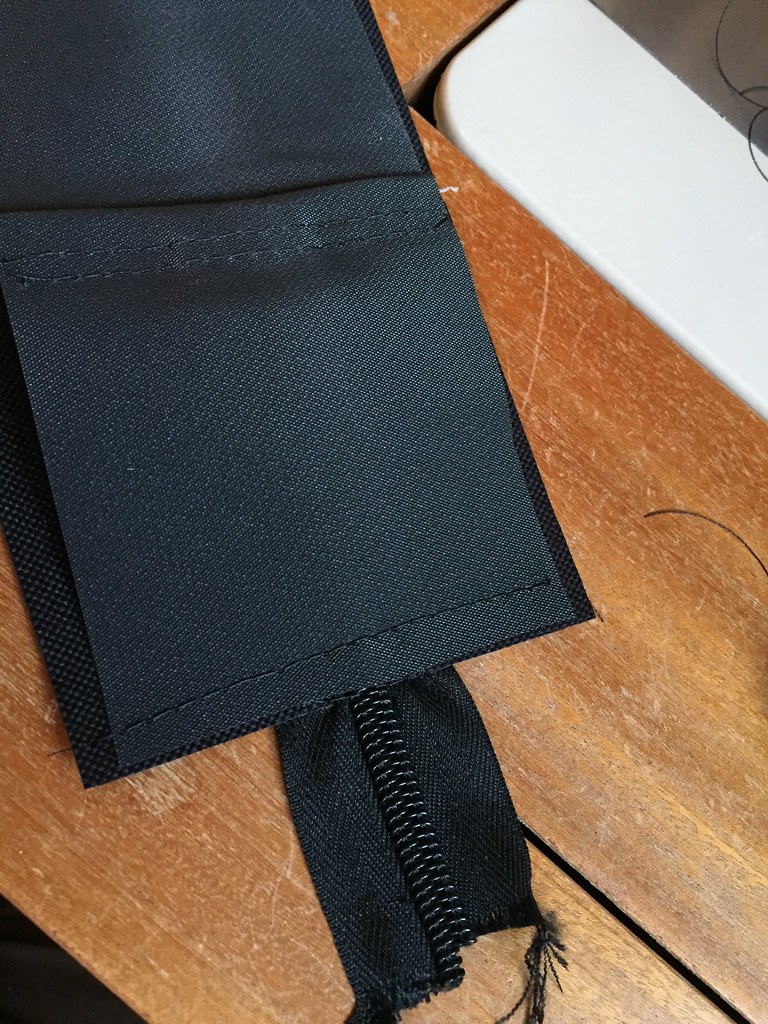

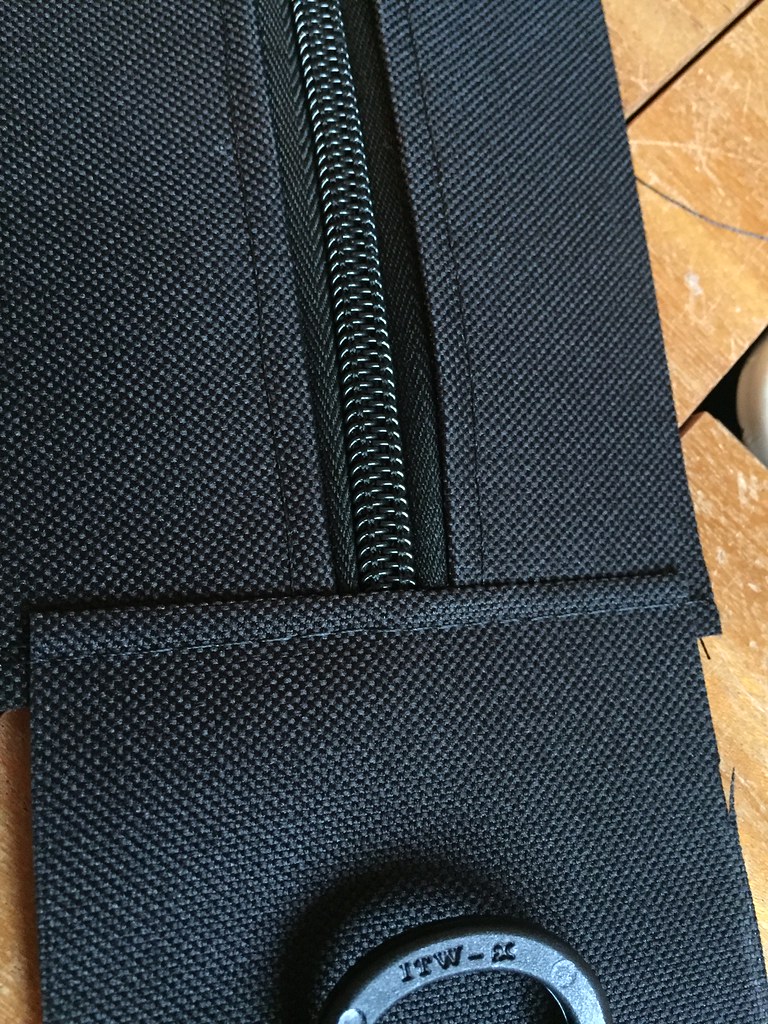

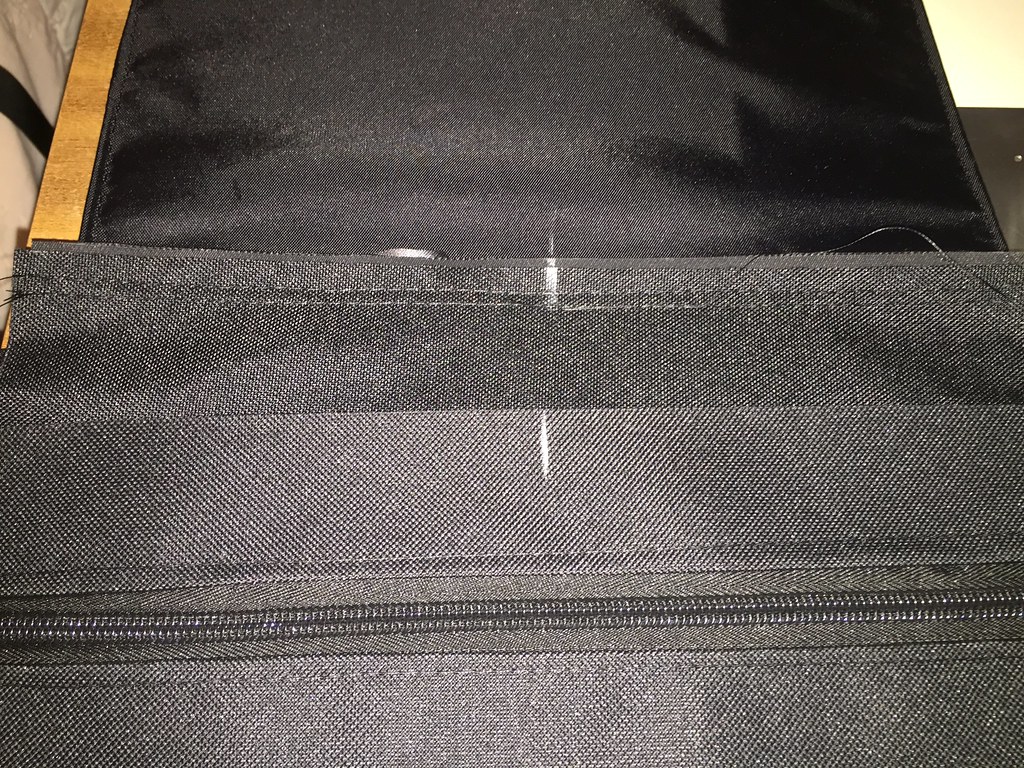

Zips. I usually buy a long piece of continuous zip and pulls. But you can also use open or closed end chunky zips, it does not matter as long as they are longer than the opening you are doing, this will become clearer later on.

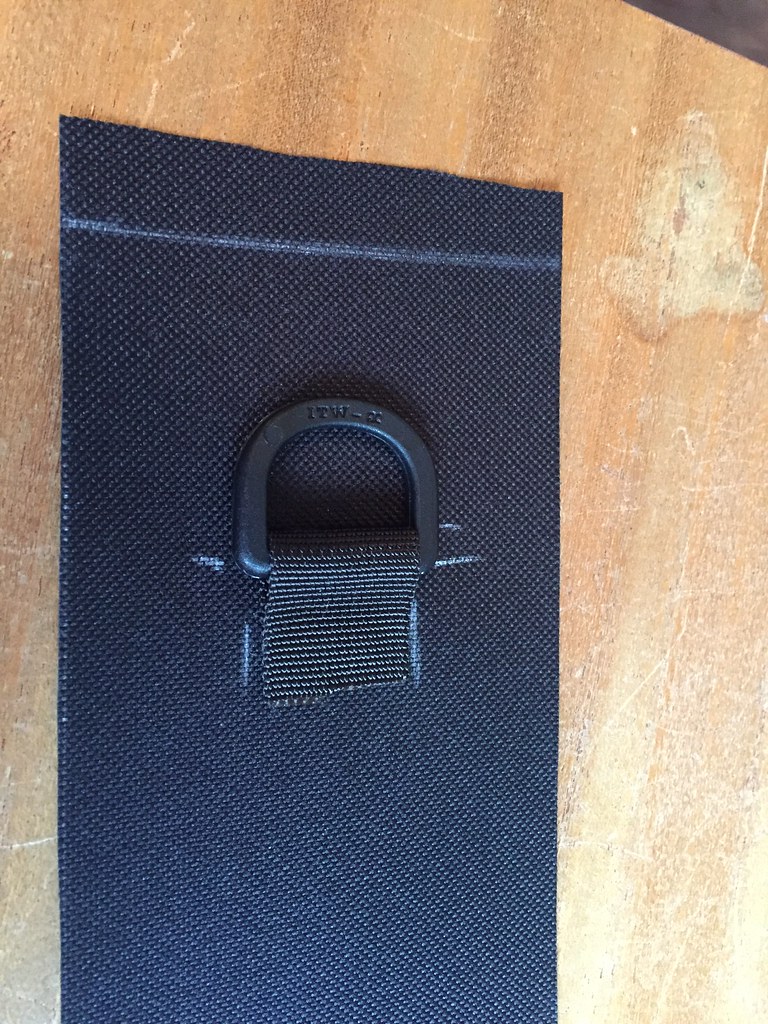

Plastic hardware. I always use ITW Nexus.

Other things I use are, tailors chalk, rulers, scissors and sail making tape.

If you need to know suppliers of various parts, please PM me and I will send you a list of who I have used in the past and am happy with their products.

Next Basic construction

Lets start with the basics required for a small shoulder bag. This one is going to be loosely based on the Mk4 Gasmask / Indiana Jones bag.

Sewing machine is a must, I started with my wifes bog standard domestic machine. It could quite happily cope with a few layers of 1000d material, so would be fine for this project.

Needles and thread. I use denim/jeans needles and Coat Nylbond 60 thread. This works well for me and I would think it is a good starting place for anyone starting. Dunelm Mills stock both and are one of the cheapest places for the thread, although a little limited on colours.

Material. I usually use 1000d or 600d material, although have also used Goretex as well. I sometimes line with a different material, but for ease you can use the same on the inside and outside of the bag.

Unless the bag is for something really special (when I will use genuine 1000d Corudra) I tend to use 600d material from Ebay.

Zips. I usually buy a long piece of continuous zip and pulls. But you can also use open or closed end chunky zips, it does not matter as long as they are longer than the opening you are doing, this will become clearer later on.

Plastic hardware. I always use ITW Nexus.

Other things I use are, tailors chalk, rulers, scissors and sail making tape.

If you need to know suppliers of various parts, please PM me and I will send you a list of who I have used in the past and am happy with their products.

Next Basic construction