also try not to round off the spine so it can strike a firesteel.

i'll vote wyldwood too, great name. can't wait for this one.

i'll vote wyldwood too, great name. can't wait for this one.

Files lines would be great, it will help the grip in the absence of the Spyderco 'Hump'Nemisis said:Any plans for file lines along the back as a thumb grip like on the grohmann?

sal. said:Great pics Hoodoo, thanx much.

Martyn, we ground the first pattern full flat as I needed to do an edge retention run on the CATRA. When we test mules, we grind flat with consistent edge angles so the tests are comparable. We've not tested 52100 yet so this is a good opportunity.

I agree. It'll be interesting to see which knife sells better in which area.On the modern ("NASA") version, we'll more than likely go full flat as I believe that market will prefer the full flat grind.

On the "traditional" version, we're open. There does seem to be some differences in preference.

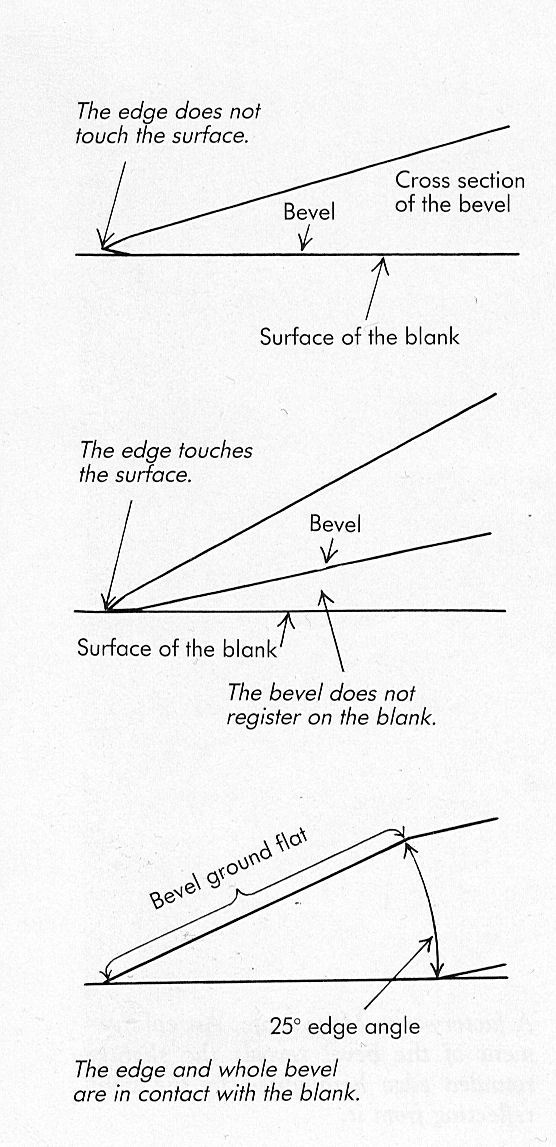

I must say that I am a bit confused by the seemingly contradictory statements of "scandi" grind requiring a "flat" flat stone, and the "sharpening on a rock" adaptability.

I do not think that I could sharpen a scandi grind on a rock and do a good job.

sal. said:Thanx for the input Martyn. Next, what is the ideal inclusive angle for a scandi grind?

I think that's what the woodlore is. The Bearclaw field knife is 40totalMartyn said:I've got 40 degrees in me head Sal, but I've no idea where from.