In the thread 'Wood-gas stove for developing countries'

http://www.bushcraftuk.com/forum/showthread.php?t=84396&highlight=

.

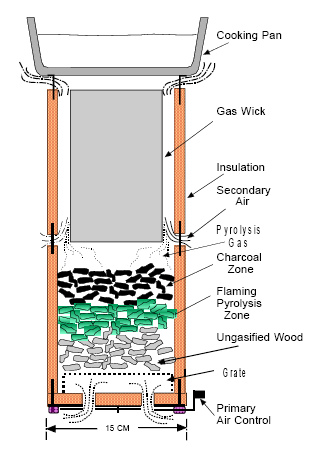

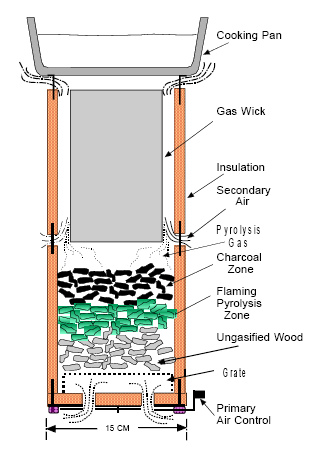

I asked if anyone had made a stove to the actual design in the paper:

http://www.waoline.com/science/newen...odGasStove.pdf

.The main schematic is:

.

No-one seemed to have done it so I thought I would have a go.

.

(People skilled at metal work should be sitting down and away from sharp objects when reading the remainder.)

.

The finished stove looked something like this:

.

.

SUMMARY

.

My impementation of the design did not work well but it has given me some ideas for another stove.

I set out here what I did in case it is of help to someone else with better ideas, skills and tools than me

.

MATERIALS

Two large heinz tomato soup cans and a baked bean can

.

PARTICULAR POINTS

.

(1) the valve at the bottom was relatively simple to make and could be a useful feature in other stoves

.

.

.

as it gives some control over air flow.

.

(2) Because of the valve in the bottom you need a grate - I just used screwed up galvanised wire as it was all I had - worked well enough for my trial, but something like the grid off a disposable BBQ would probably be better

.

.

(3) I tried various ways of holding the 'gas wick' in place

.

.

.

but in the end I just rested it on the bolts on the inside

.

.

.

(4) with the annular ring reduced to about 5mm the flame was a deep orange with occasional hints of blue, so the design seemed to be having some effect on the flame/efficiency of burn

.

.(

5) Insulating the unit (top and bottom halves) would probably have improved the gasification but as it was the bottom tin can was getting red hot

.

.

so if you want to have a go at this then it would be better to use a more robust lower unit

.

(5) I read the design to require that you clip the upper part to the lower part after you have lit the fire. I didn't know how I might do that. Even better if you were to use a method that allowed you to easily adjust the gap. I had to make do with nuts and bolts and it was a faff to amend/correct things eg when I forgot to put the grate in and again when I changed the annular gap

.

(6) You put the fuel in and then light the fire from the top

.

.

I added a bit of tinder and used a fire lighter to get it going

.

(7) The unit should have legs. These weren't essential for my tests but if you have a go then I think you should have only three legs , suitably positioned so that you can still open and close the valve fully

.

(8) You need some way of providing a pot rest that allows a gap for the flames to appear at the top - not essential for my test

.

NEXT TIME

.

Well ... as regards this design there won't be a next time for me. When I get the urge I might have a go at a stove which is just this:

.

.

or something like it

And if anyone ever does make a stove to the original design I'd be more than interested to hear how it worked

http://www.bushcraftuk.com/forum/showthread.php?t=84396&highlight=

.

I asked if anyone had made a stove to the actual design in the paper:

http://www.waoline.com/science/newen...odGasStove.pdf

.The main schematic is:

.

No-one seemed to have done it so I thought I would have a go.

.

(People skilled at metal work should be sitting down and away from sharp objects when reading the remainder.)

.

The finished stove looked something like this:

.

.

SUMMARY

.

My impementation of the design did not work well but it has given me some ideas for another stove.

I set out here what I did in case it is of help to someone else with better ideas, skills and tools than me

.

MATERIALS

Two large heinz tomato soup cans and a baked bean can

.

PARTICULAR POINTS

.

(1) the valve at the bottom was relatively simple to make and could be a useful feature in other stoves

.

.

.

as it gives some control over air flow.

.

(2) Because of the valve in the bottom you need a grate - I just used screwed up galvanised wire as it was all I had - worked well enough for my trial, but something like the grid off a disposable BBQ would probably be better

.

.

(3) I tried various ways of holding the 'gas wick' in place

.

.

.

but in the end I just rested it on the bolts on the inside

.

.

.

(4) with the annular ring reduced to about 5mm the flame was a deep orange with occasional hints of blue, so the design seemed to be having some effect on the flame/efficiency of burn

.

.(

5) Insulating the unit (top and bottom halves) would probably have improved the gasification but as it was the bottom tin can was getting red hot

.

.

so if you want to have a go at this then it would be better to use a more robust lower unit

.

(5) I read the design to require that you clip the upper part to the lower part after you have lit the fire. I didn't know how I might do that. Even better if you were to use a method that allowed you to easily adjust the gap. I had to make do with nuts and bolts and it was a faff to amend/correct things eg when I forgot to put the grate in and again when I changed the annular gap

.

(6) You put the fuel in and then light the fire from the top

.

.

I added a bit of tinder and used a fire lighter to get it going

.

(7) The unit should have legs. These weren't essential for my tests but if you have a go then I think you should have only three legs , suitably positioned so that you can still open and close the valve fully

.

(8) You need some way of providing a pot rest that allows a gap for the flames to appear at the top - not essential for my test

.

NEXT TIME

.

Well ... as regards this design there won't be a next time for me. When I get the urge I might have a go at a stove which is just this:

.

.

or something like it

And if anyone ever does make a stove to the original design I'd be more than interested to hear how it worked

Last edited: