I received a small package through the post this morning, upon opening it i found this sitting there from Adam at JLT Knives

We were talking about these the other day and Adam kindly made and sent me a blade so that i could handle it myself, we had discussed stick tangs and all sorts of options for mounting the blade in a handle, Adam was right though a couple of holes in the tang allows for a multitude of different options, you can mount it on the top, at the bottom or if you are clever in the middle if your chosen handle material, i decided to mount this particular blade on the bottom of the handle.

Onto material choice for the handle, in this case im using well seasoned Elm, because A) i have a good stock of it, B) it's as tough as old boots & C) because it looks great when it's finished.

Marking out the rough area for the handle on the blank, the blank was taken down to the round on my shave horse with the draw knife and spoke shave

the rough shape, again all done with the draw knife

cutting out the channel for the tang

checking it for a good fit

working the tang cover plate, this is made from Ash (Fraxinus excelsior)

time to work out the area to be whipped over with cord and then carefully whittled down to make a recess for the cordage to sit it

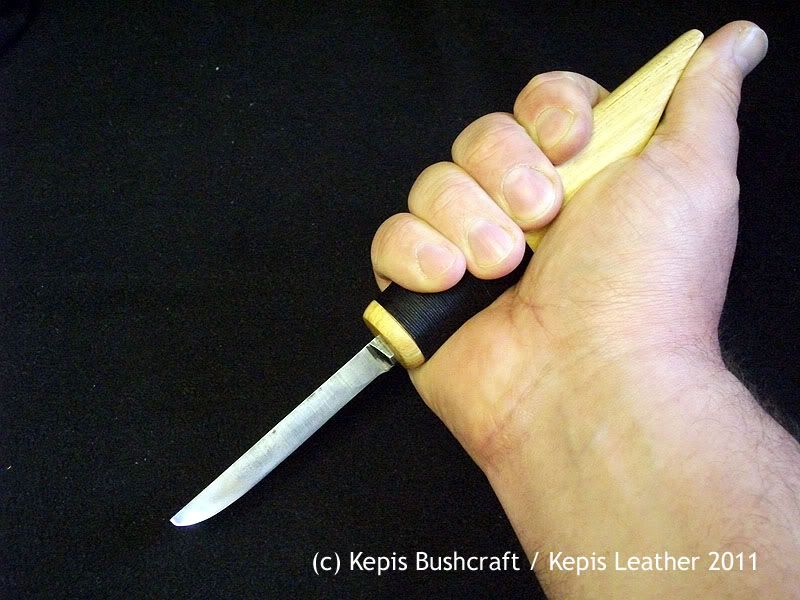

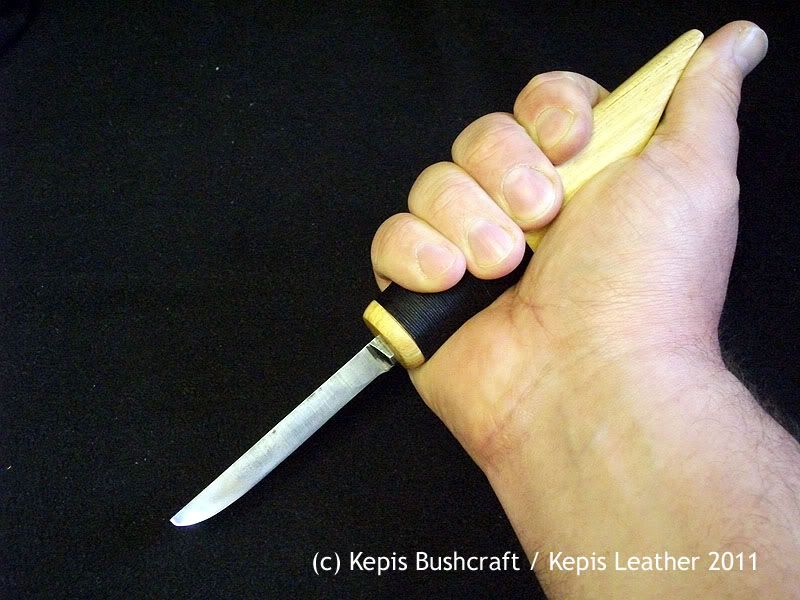

the new one and my older one, i made the new one with a different handle shape on purpose as i wanted a more or less cylindrical handle so i can use the knife for bowl and pot carving and general hollowing out and the cylindrical handle is more versatile and comfortable for the different grips used.

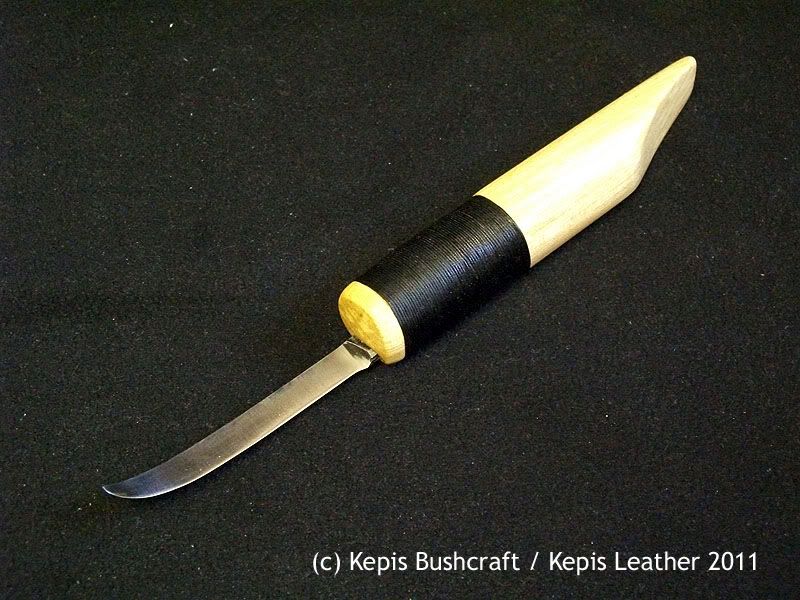

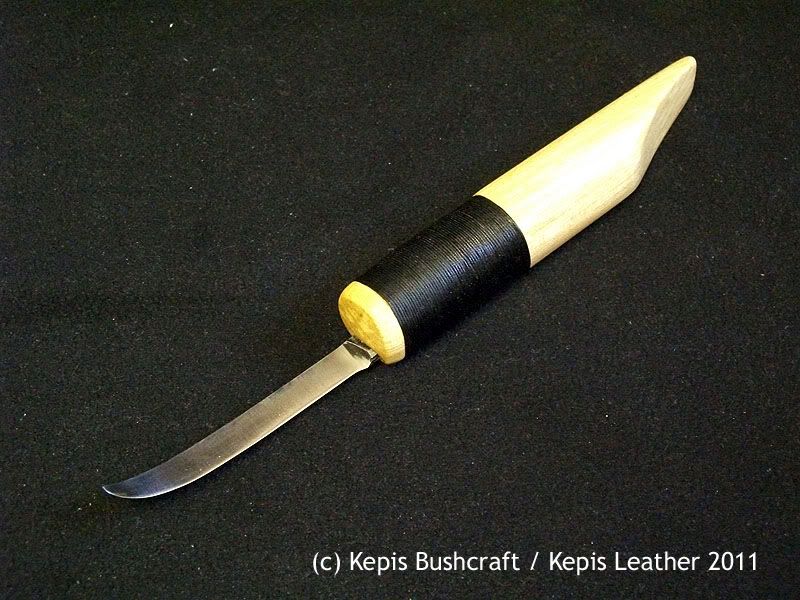

give everything a good sand down to 600 grit (except the cord recess which i left in the rough) then get it whipped up nice and tight and it's finished bar oiling the wood up

a perfect fit

I spent a bit of time using the completed knife this afternoon once i had finished it and it works a treat, the blade has a tiny amount of flex in it, but i like that, i shall give the blade a good work out as soon as i have a piece of wood that's right to carve a bowl from (im up the woods tomorrow :4 , but so far the blade has done some planing and general smoothing and it works a treat.

, but so far the blade has done some planing and general smoothing and it works a treat.

More info from Adam at www.jltknives.co.uk no affiliation to Adam other than im a happy customer.

We were talking about these the other day and Adam kindly made and sent me a blade so that i could handle it myself, we had discussed stick tangs and all sorts of options for mounting the blade in a handle, Adam was right though a couple of holes in the tang allows for a multitude of different options, you can mount it on the top, at the bottom or if you are clever in the middle if your chosen handle material, i decided to mount this particular blade on the bottom of the handle.

Onto material choice for the handle, in this case im using well seasoned Elm, because A) i have a good stock of it, B) it's as tough as old boots & C) because it looks great when it's finished.

Marking out the rough area for the handle on the blank, the blank was taken down to the round on my shave horse with the draw knife and spoke shave

the rough shape, again all done with the draw knife

cutting out the channel for the tang

checking it for a good fit

working the tang cover plate, this is made from Ash (Fraxinus excelsior)

time to work out the area to be whipped over with cord and then carefully whittled down to make a recess for the cordage to sit it

the new one and my older one, i made the new one with a different handle shape on purpose as i wanted a more or less cylindrical handle so i can use the knife for bowl and pot carving and general hollowing out and the cylindrical handle is more versatile and comfortable for the different grips used.

give everything a good sand down to 600 grit (except the cord recess which i left in the rough) then get it whipped up nice and tight and it's finished bar oiling the wood up

a perfect fit

I spent a bit of time using the completed knife this afternoon once i had finished it and it works a treat, the blade has a tiny amount of flex in it, but i like that, i shall give the blade a good work out as soon as i have a piece of wood that's right to carve a bowl from (im up the woods tomorrow :4

More info from Adam at www.jltknives.co.uk no affiliation to Adam other than im a happy customer.