I've been wanting an adze for a while now, and I have been experimenting with a rudimentary forge set up, so I was able to bash out the blade for this.

Adze1 by Alan Muddypaws, on Flickr

Adze1 by Alan Muddypaws, on Flickr

Adze 3 by Alan Muddypaws, on Flickr

Adze 3 by Alan Muddypaws, on Flickr

The blade is forged from a piece of leaf spring, but it is quite small (the bar started out only three quarters of an inch wide), so doesn't have much heft to it.

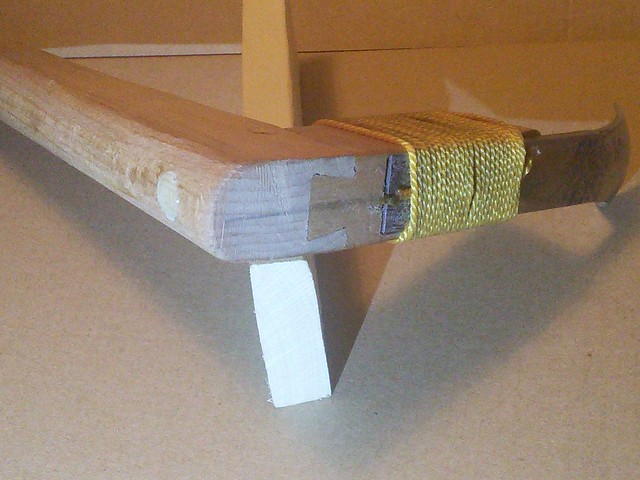

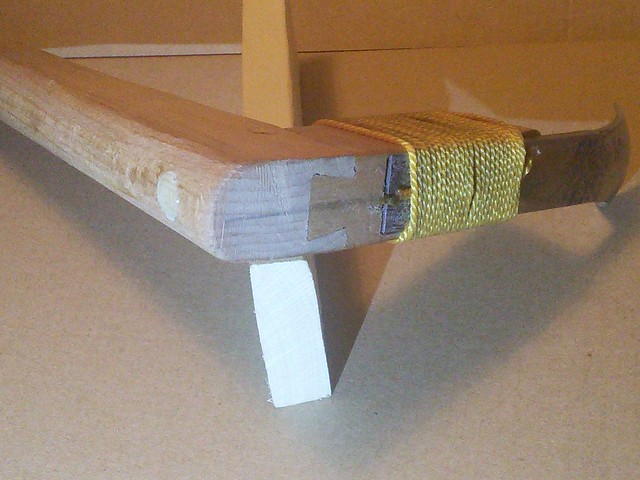

I didn't have any really suitable timber for the handle, so my bodged up compromise is a two piece elbow, dovetailed, glued, dowelled and a couple of small woodscrews for good measure. Hopefully these pictures will show how this was achieved.

Adze2 by Alan Muddypaws, on Flickr

Adze2 by Alan Muddypaws, on Flickr

Handle joint by Alan Muddypaws, on Flickr

Handle joint by Alan Muddypaws, on Flickr

I owe a debt of gratitude to Robson Valley, for all his posts about his Pacific Northwest tools, and for the links to Kestrel tools, all of which has given me valuable pointers for sharpening and mounting the blade.

In use I have found this adze to be a useful addition to my toolkit. I hollowed out a small dish in quick time, needing only minimal cleanup with a hook knife. Previously I would have tried to remove the bulk of the waste with a drill and Forstner bit, before using a spoon bent gouge.

That said, I know it is not perfect, so I already have plans for adze mark 2, with a wider, heavier blade, a shallower sweep, and not so much forward curve. Needless to say, I will keep you posted.

Thanks for looking.

Adze1 by Alan Muddypaws, on Flickr

Adze1 by Alan Muddypaws, on Flickr Adze 3 by Alan Muddypaws, on Flickr

Adze 3 by Alan Muddypaws, on FlickrThe blade is forged from a piece of leaf spring, but it is quite small (the bar started out only three quarters of an inch wide), so doesn't have much heft to it.

I didn't have any really suitable timber for the handle, so my bodged up compromise is a two piece elbow, dovetailed, glued, dowelled and a couple of small woodscrews for good measure. Hopefully these pictures will show how this was achieved.

Adze2 by Alan Muddypaws, on Flickr

Adze2 by Alan Muddypaws, on Flickr Handle joint by Alan Muddypaws, on Flickr

Handle joint by Alan Muddypaws, on FlickrI owe a debt of gratitude to Robson Valley, for all his posts about his Pacific Northwest tools, and for the links to Kestrel tools, all of which has given me valuable pointers for sharpening and mounting the blade.

In use I have found this adze to be a useful addition to my toolkit. I hollowed out a small dish in quick time, needing only minimal cleanup with a hook knife. Previously I would have tried to remove the bulk of the waste with a drill and Forstner bit, before using a spoon bent gouge.

That said, I know it is not perfect, so I already have plans for adze mark 2, with a wider, heavier blade, a shallower sweep, and not so much forward curve. Needless to say, I will keep you posted.

Thanks for looking.