D

DANKO

Guest

Custom Victorinox - Swiss Army Soldier Knife

I am pleased to share with you ..........

A few days ago, having few hours to spare and not knowing what to do, I have depleted to a project that I bounced over the head with when, for birthday, gave me this beautiful Victorinox Soldier 11.

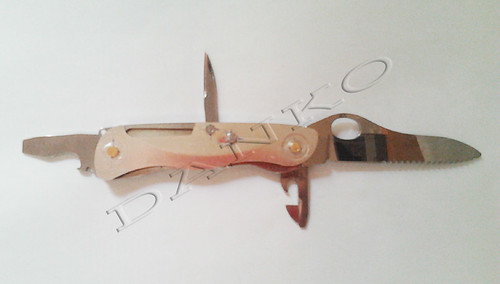

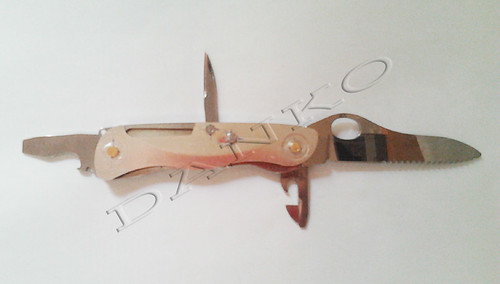

In fact I've customized the Soldier adding a blade flush with the floor on block (the blade combo will be useful but I am of the opinion that a flat edge blade should never be missing out on a multi-purpose tool), taken from One Hand Sentinel unVictorinox bought items used on a stand at the modest sum of 9, then I inserted taking it from Victorinox Dual Pro which had been given to my father (and he does not use because he said it is too heavy as it is accustomed to his old, worn pattadesa ) curved serrated blade with rounded point course along with its safety lock.

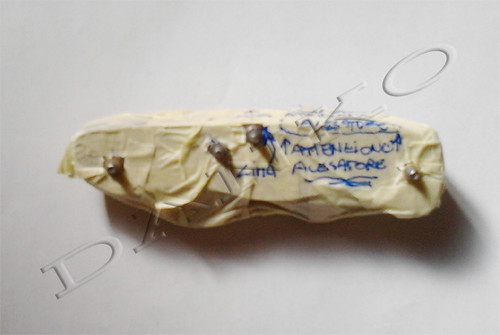

Obviously, to do what I have destroyed the One Hand Sentinel, from which I recovered, however, toothpick, tweezers and cheeks (as you will see that I mounted on the Dual Pro) while the Dual Pro has been disassembled and reassembled without a curved blade and consequently without the corkscrew, then I have not thrown anything away except for a side bulkhead aluminum Sentinel that unfortunately I deformed for the rest of what has been dismantled and was reassembled on a Victorinox or the other was kept as a spare part (see the red cheeks of the dual Pros and corkscrew).

It must be said, and I want to specify it, this customization was born to my need to have at hand a complete and versatile tool that would allow me, since I spend much time in the countryside between vegetables and animals from various rearing, to juggle several activities that involve, for example, the large blade flush floor is good for me to work the wood while the curved blade and serrated edge is excellent for the evisceration of the piglets during the slaughter, and that I accompany even during outdoor activities.

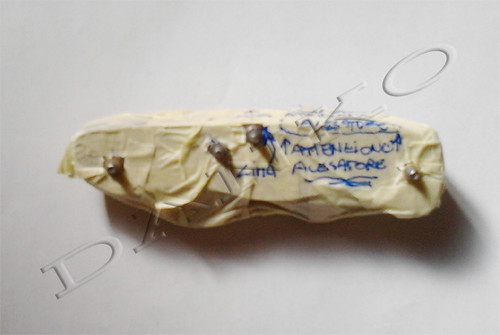

To do this fine job I used my faithful dremel with relative inserts while instead of the brass rivets original I used stainless steel screws from 3 to 2.5 mm (the head, replaced by a nut to distribute better, on both sides , the force of tightening) and accompanied by the respective nuts (brass screws from 3 easier to touch up), all for a cost which is around 5-6.

It goes without saying that the dice are rounded and polished for good so that they fit perfectly with the notches securing places on the inside of the cheeks.

For those who want to challenge themselves in such an alteration of a Victorinox advice during the assembly phase, pay close attention during the tightening of nuts as they are tight with millimetric movements so as not to lose "snap effect" of the various components.

In conclusion I am very very pleased with the outcome as well as obtain a robust and efficient tool to work, I have reshaped my way while maintaining the merits (the blades one hand for example start with a very simple course with the right hand and one with the left, etc..) of an original Victorinox.

But here are the pictures (sorry for quality) for the various steps that led to the construction of my new Victorinox Soldier Custom.

Forgive the errors of language!

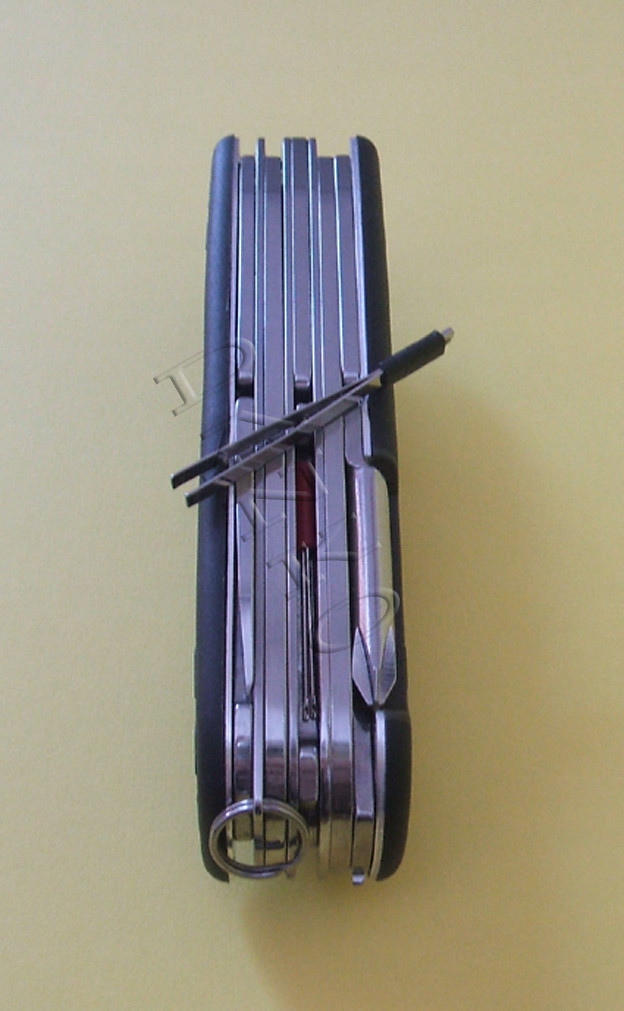

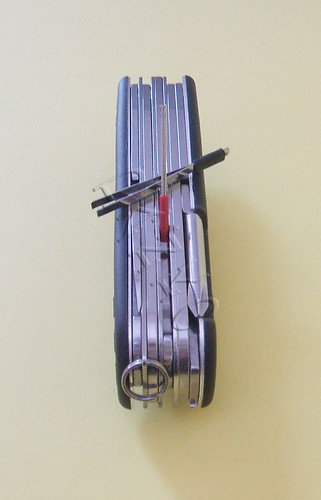

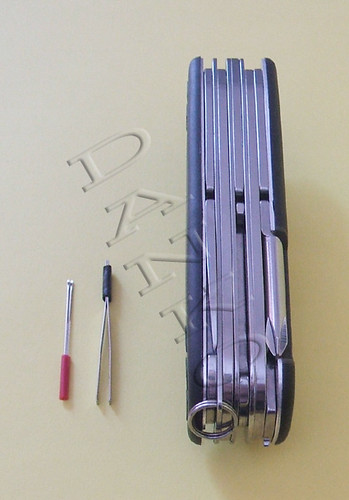

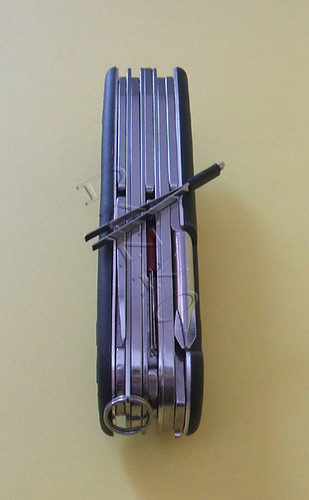

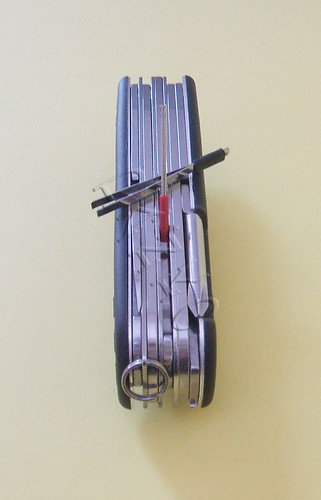

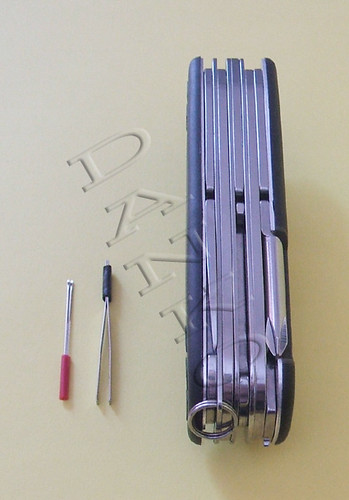

1,2 Photo Disassembly Victorinox Sentinel

3 Photo Victorinox Soldier the original version

3 Photo Victorinox Soldier the original version

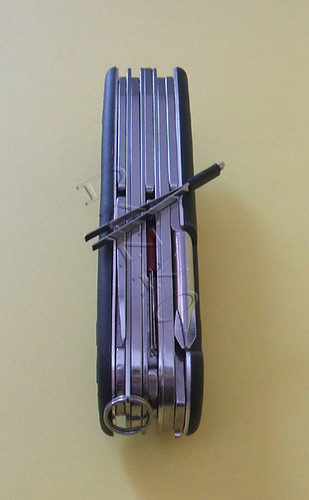

4,5 Photos Disassembly Victorinox Soldier

4,5 Photos Disassembly Victorinox Soldier

6,7,8,9,10 Photos Custom Mounting new Victorinox Soldier

6,7,8,9,10 Photos Custom Mounting new Victorinox Soldier

11 Photo Modified installation Victotinox Dual Pro

11 Photo Modified installation Victotinox Dual Pro

12,13,14,15,16,17,18,19,20 Photos Details new Victorinox Soldier Custom. Note the space obtained by needle and tweezers

12,13,14,15,16,17,18,19,20 Photos Details new Victorinox Soldier Custom. Note the space obtained by needle and tweezers

21,22 Photos Comparison new Victorinox Soldier Victorinox Dual Pro Custom and modified

21,22 Photos Comparison new Victorinox Soldier Victorinox Dual Pro Custom and modified

23 Photo Comparison (from left) changed from Victorinox Dual Pro, Victorinox Trailmaster original, brand new Custom Victorinox Soldier

23 Photo Comparison (from left) changed from Victorinox Dual Pro, Victorinox Trailmaster original, brand new Custom Victorinox Soldier

.......... I hope you like it !

!

Greetings.

Dk.

Victorinox Soldier - Custom for me!

I am pleased to share with you ..........

A few days ago, having few hours to spare and not knowing what to do, I have depleted to a project that I bounced over the head with when, for birthday, gave me this beautiful Victorinox Soldier 11.

In fact I've customized the Soldier adding a blade flush with the floor on block (the blade combo will be useful but I am of the opinion that a flat edge blade should never be missing out on a multi-purpose tool), taken from One Hand Sentinel unVictorinox bought items used on a stand at the modest sum of 9, then I inserted taking it from Victorinox Dual Pro which had been given to my father (and he does not use because he said it is too heavy as it is accustomed to his old, worn pattadesa ) curved serrated blade with rounded point course along with its safety lock.

Obviously, to do what I have destroyed the One Hand Sentinel, from which I recovered, however, toothpick, tweezers and cheeks (as you will see that I mounted on the Dual Pro) while the Dual Pro has been disassembled and reassembled without a curved blade and consequently without the corkscrew, then I have not thrown anything away except for a side bulkhead aluminum Sentinel that unfortunately I deformed for the rest of what has been dismantled and was reassembled on a Victorinox or the other was kept as a spare part (see the red cheeks of the dual Pros and corkscrew).

It must be said, and I want to specify it, this customization was born to my need to have at hand a complete and versatile tool that would allow me, since I spend much time in the countryside between vegetables and animals from various rearing, to juggle several activities that involve, for example, the large blade flush floor is good for me to work the wood while the curved blade and serrated edge is excellent for the evisceration of the piglets during the slaughter, and that I accompany even during outdoor activities.

To do this fine job I used my faithful dremel with relative inserts while instead of the brass rivets original I used stainless steel screws from 3 to 2.5 mm (the head, replaced by a nut to distribute better, on both sides , the force of tightening) and accompanied by the respective nuts (brass screws from 3 easier to touch up), all for a cost which is around 5-6.

It goes without saying that the dice are rounded and polished for good so that they fit perfectly with the notches securing places on the inside of the cheeks.

For those who want to challenge themselves in such an alteration of a Victorinox advice during the assembly phase, pay close attention during the tightening of nuts as they are tight with millimetric movements so as not to lose "snap effect" of the various components.

In conclusion I am very very pleased with the outcome as well as obtain a robust and efficient tool to work, I have reshaped my way while maintaining the merits (the blades one hand for example start with a very simple course with the right hand and one with the left, etc..) of an original Victorinox.

But here are the pictures (sorry for quality) for the various steps that led to the construction of my new Victorinox Soldier Custom.

Forgive the errors of language!

1,2 Photo Disassembly Victorinox Sentinel

.......... I hope you like it

Greetings.

Dk.

Last edited by a moderator: