Ok time for part 2

My apologies for not posting this sooner but things have been pretty chaotic here, busy at work and getting ready to move house!!

but things have been pretty chaotic here, busy at work and getting ready to move house!!

So lets continue.......and return to the Hults Bruk foundry

In part 1 you saw Cegga's colleagues forging the head of a Hultafors felling axe.

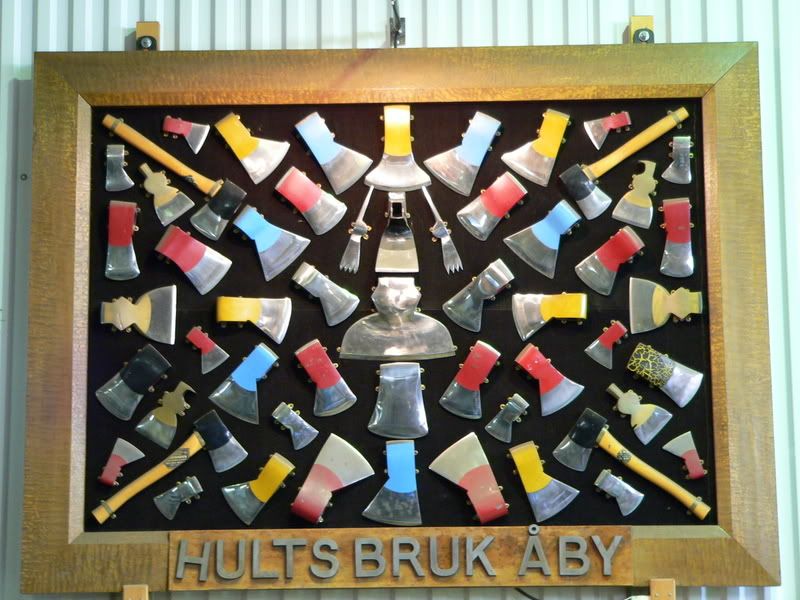

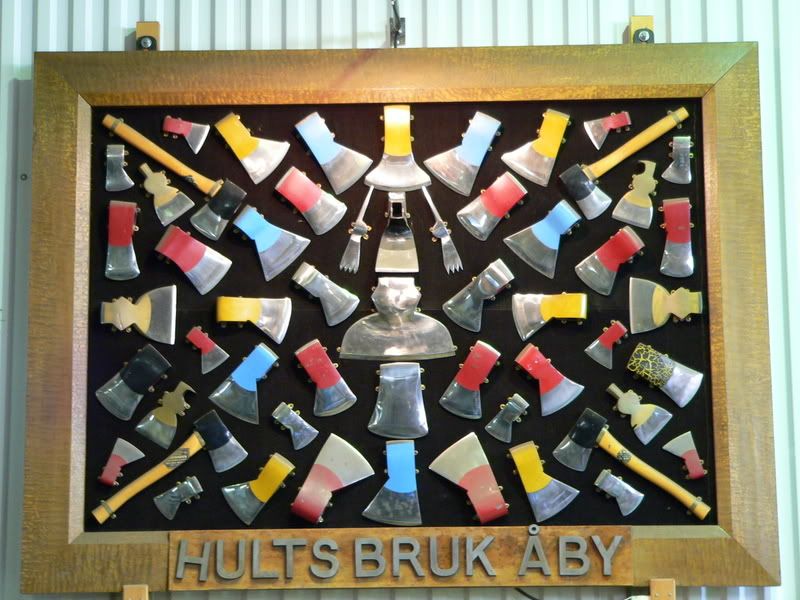

The Hults Bruk foundry produce several models of axe.

Check out the products panel on the right hand side of this link.

http://www.hultafors.co.uk/default.asp

It appears they produce a run of one model at a time and tool up the machinery accordingly. So as Cegga gave us the guided tour we were able to see further stages of poduction of same model of axe.

So here we have the finished head ready to be fitted with the handel.....................

excuse my poor photo of Ceggas lightening fast thumb!

The handels ready to be fitted.

Cegga's colleague opperating the machine that fits the handels.

Once the handel is fitted the cutting edge is dipped into a rubbery type material to provide some protection.

We saw some of the Hultafors "Classic" models assembled and ready to be packed.

However there were loads of different styles of axe head waiting to be assembled.

Ok enough for now part 3 to follow.

My apologies for not posting this sooner

So lets continue.......and return to the Hults Bruk foundry

In part 1 you saw Cegga's colleagues forging the head of a Hultafors felling axe.

The Hults Bruk foundry produce several models of axe.

Check out the products panel on the right hand side of this link.

http://www.hultafors.co.uk/default.asp

It appears they produce a run of one model at a time and tool up the machinery accordingly. So as Cegga gave us the guided tour we were able to see further stages of poduction of same model of axe.

So here we have the finished head ready to be fitted with the handel.....................

excuse my poor photo of Ceggas lightening fast thumb!

The handels ready to be fitted.

Cegga's colleague opperating the machine that fits the handels.

Once the handel is fitted the cutting edge is dipped into a rubbery type material to provide some protection.

We saw some of the Hultafors "Classic" models assembled and ready to be packed.

However there were loads of different styles of axe head waiting to be assembled.

Ok enough for now part 3 to follow.